rbernie

Contributing Member

I've read 'em. Nowhere in them do I see a comprehensive discussion of the dynamics of the roller locking system within the CETME to a sufficient level of detail required for me to throw away the 'conventional wisdom' and replace it with yours.I have posted my affirmative ideas dozens of times on various gun sites. I have also posted references to discussions which I consider worthwhile. These can be found easily using Google.

I'm not adverse to doing so.

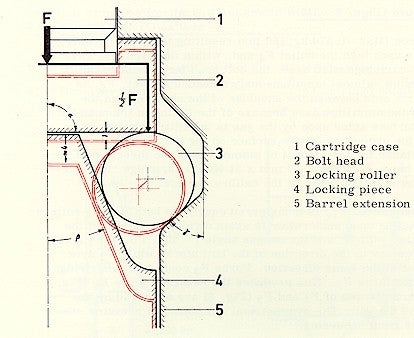

But you need to consolidate your thoughts into a discussion that starts with the forces and mechanical relationships that halt the bolt's forward movement into battery when the chamber is both empty and loaded, progresses into how the linear vector of the bolt under rearward pressure is converted by the rollers into a force that acts upon on the locking piece, describes the location/orientation of all of the relevant parts (dynamic and static) while the bolt is in battery and fully locked and how each reacts to the rearward pressure on the bolt face, and concludes by examining the 'timing' of the bits in play in the event that they deviate from the manufacturers specified tolerances (e.g. the bolt is ground shorter than its minimum specificed length).

In the absence of this complete picture, you're asking folks to take your word in regards to this. In doing so, you place yourself in no different light than anyone else in the conversation, but without the benefit of the manufacturer's specified tolerances to cover your fanny.

<shrug> Your call. But you started a thread that demanded attention to your ideas. It seems kinda silly to abandon it when you're so convinced that you're correct.Since I have made my points as best I can, in THR, a forum not dominated by a Cetme "expert," I will retire from this discussion and let others continue it, if they wish.

Personally, I think that a ground bolt in part compensates for the fact that the barrel is too far to the rear in the trunnion and that the bolt cannot fully and properly enter into battery with in-spec ammo (headspace, if you will) unless the bolt itself is shortened to compensate. But shortening the bolt, in turn, reduces the distance available for the rollers to operate (since the bolt is further to the rear of the recesses than it was originally designed to operate). If the rollers cannot retract sufficiently by the time they reach the end of their recesses (they're still too far down the ramp of the locking piece), the supporting material around the rear of the locking recesses will take one hellova beating and this may cause significant damage to the barrel/receiver over time. I believe that the rationale for having in-tolerance bolt lengths and bolt gaps and locking piece dimensions and such is to both time the unlocking of the action relative to the dynamic bits but also to time the unlocking of the action relative to the stationary bits (the locking recesses, etc.).

You may be able to compensate for a shorter-than-normal bolt by playing with the dimensions of the locking piece and size of the rollers, but in the end you're pushing around a very small window within which things will operate correctly (and running an increasing risk of getting it wrong such that the bolt doesn't fully lock up, etc.). The factory specs are designed to create a larger window, timing-wise and wear-wise, for all of that to occur.

But that's just my theory, and is worth no more than anyone elses.