FAL continued:

ok, with inch vs. metric (partially!) covered, let's move on to the part by part.....

indicates applicable "922r(ubbish) compliance part" candidates, followed by approximate cost of a US made item

-muzzle device.

$30-up

the standard late 'metric' barrel is threaded at the muzzle 9/16-24 LH thread.

most often encountered attachment is the 'combo device' which functions as a flash hider, is threaded internally for a

blank firing attachment and is 22mm in diameter to match NATO rifle grenades and a tube or socket-style bayonet.

some had flats at their midpoint (fore to aft), others' were further to the rear of the device.

also 9/16-24LH and fairly common; the long, pronged, perhaps menacing-looking 'Stoll' flash hider designed by the namesake Austrian Major for the StG58 adopted by and manufactured under license in his home country at Steyr.

the Stoll device's intended use was for grenades, flash reduction, and wire-cutting but not bayonet fitment.

the OD will accept a tube-bayo but no flats are present to retain it.

maybe it was designed that way so if you actually used the bayo and it stuck, you could pull the rifle away easily.....

(these ring like a tuning fork. i could swear my 58 sings sometimes while it fires)

the Stoll is often found with the ribbed rear section (which overhangs the barrel to the rear of the device's internal threads)

turned off to create a 'shorty-Stoll' which IMO compliments a carbine build nicely.

there are also unthreaded devices and different types of lugged barrels. the German G1 pattern is probably the most prevalent lugged barrel in the US and the QD flash hider, BF & GL attachments made for it will not fit the earlier style lugged barrels.

shortly after adopting the G1, Germany went to the G3 reportedly because they could be made in-house and they were denied License by FN.

the Turks who took possession of the G1s created or converted bayonets to fit over the flash hider.

there are also a number of aftermarket (read: US made /designed ) hiders with windy or sometimes stormy or ornery-animal-sounding names which reportedly work exceptionally well at flash signature and / or recoil reduction.

here are a few front end arrangements. L-R

DSA SA58 w/integral brake, a shorty-Stoll, Turk bayo w/FH for lugged G1, socket bayo & scab. for combo device, StG58 w/Stoll FH

which brings us to

-BARRELS.

$100-up for good used surplus. DSA sells new US made in standard, medium and heavy contour $250-up

in my limited experience among the least-used surplus seem to be the StG58 barrels, often found nearly pristine.

kits out of South America often exhibit far more handling wear than internal bore wear.

G1 barrels and those from kits out of Africa are often very well worn with dark or pitty (pity!) bores and / or (G1s especially) leaky gas blocks.

major variations:

LENGTH

production model barrel lengths per Blake's book was thus:

(inch conversions rounded off [roughly:21, 18 & 17-1/8"])

50.61 standard barrel (533mm/20.984"), steel lower

50.64 standard barrel (533mm/20.984"), alloy lower

50.63 458mm/18.031" or 436mm/17.165" ?with either lower/barrel combo?

of course this is just para models but i believe the only issue-length barrel for (50.00) non-paras was 533mm/20.984"

LINE of SIGHT

as was touched on in the inch vs. metric preamble, there are open ear metric barrels with the higher line of sight.

in a standard metric-parts build they may be used by adding a taller inch or Indian rear sight or Israeli aperture which will fit the metric base.

likewise then an inch barrel may be used with other metric parts so long as sight plane is considered in this manner.

an aside on front sight posts i don't have any experience with the metric open ear version but closed ear metric blocks utilize front sight posts usually marked with a multiple of 'dots' (starting w/none) to indicate their height; dots are not to be confused with the holes for the sight adjusting tool which are larger and opposite one another.

Unmarked - 5.5 mm

1- 6.0 mm

2- 6.5 mm

3- 7.0 mm

4- 7.5 mm

there are aftermarket front sight posts with tritium inserts and hooded crosshairs.

the inch uses a blade as shown above, held in place by a set screw at the front of the gas block. (7?) different height blades are also available. watch that set screw, they run away.

BIPOD CUT OR NOT:

the G1 contract was a landmark in the development of the FAL. the German-specified lower line of sight became the standard at FN.

carried on as an option were German-designed bipod and handguards made primarily of sheet metal stampings which clamped onto the barrel forward of the gas block. the legs fold rearward from the extended position to fit flush with aptly-named bipod-cut handguards.

this arrangement required an extra groove or bipod cut to be machined on the barrel to locate the bipod on. the groove for the bipod is interrupted atop the barrel to allow a key inside the top saddle of the bipod mount to limit rotation. i believe all G1 and StG58 barrels were bipod cut.

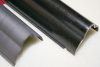

top barrel has sling cut only, barrel below is bipod cut:

-GAS SYSTEM:

-GAS PISTON.

~$25 avoid the 2-piece pistons IMO. spec for the piston head is 0.429" diameter

piston, gas cylinder (tube) and tube/carry handle bush will interchange. plugs and regulators work only in their native gas block.

-GAS PLUG:

variants include standard, StG58 with lever and the different grenade-launching sight-ladder-equipped South African variants.

standard at front, StG to left, SA plug for Energa grenade to rear

here's a GL plug installed

i believe there are plugs w/different sight-ladder heights (for dif.types of grenades?) as well.

-GAS TUBES: the vent holes in the metric tube are at 4 & 8 o'clock while inch are at 3 & 9.

most rifles have a long gas tube, threaded then pinned into the gas block and supported at the rear by a bushing which screws into the front of the receiver (capturing the carry handle in it's slot in the receiver).

most StG58 barrels had half-length tubes soldered into the gas block rather than the aforementioned system. conceivably this negates the tendancy for sloppiness to develop at this critical interface allowing gas to bypass the operating sytem. the arrangement also simplifies cleaning the internal portion of the gas system.

short tubes will expose a portion of the piston & spring inside the handguard.

this is most pronounced in conjunction with an open-topped handguard such as the uber-insulative Israeli.

but if you keep gas flowing down the tube, nothing's going to crawl in there!

comparison of standard gas tube (with Izzy HG) & StG halfie:

ok let's jump to

-HANDGUARDS.

~$20-40

for US stuff, IMO DSA > Penguin(PSAW) > century/tapco where feel & looks are compared.

DSA are best US by far IMO but aftermarket sets named felt nowhere near as sturdy as Belgian, Imbel or Argentine synthetics.

all interchange between inch, metric & Israeli light-barrel. the heavy barrel Izzy HG requires a larger diameter HG ring or a slight mod to the HG's metal liner. HB versions can be spotted by the notch they have cut out to allow for their forward-facing carry handle.

original early style solid wood HG are pretty rare in any shape above fair it seems. repros abound. i have none to show.

laminated L1A1 HG can be found in good shape and are pretty effective heat dampeners.

the Israeli are perhaps the best for thermal protection.

Australian (L1A1) laminated

here's the Izzy heavy barrel handguard, note notch at bottom left of pic

the Izzy light barrel handguard, no notch

SYNTHETIC Hg were made of many different materials. some had metal inserts at the gasblock interface, others not.

obviously they were made with and without the bipod cut which allowed the folding bipod legs to recess.

i don't believe there are any wood bipod cut guards to speak of.

non-bipod synthetic HG: (Imbel, non-factory finish)

bipod synthetic HG, metal ends:

bipod stamped steel G1 pattern (used on StG too), non-factory (DSA) finish

US made Penguin; non'pod cut, no metal ends, proprietary buttplate assembly.

DSA US made, metal ends, only bipod cut offered AFAIK

-PISTOL GRIPS.

-PISTOL GRIPS.

~$15-30

many plastic grips out there from FSE, wolfsburgbob, DSA, ergo. there are original looking, PSG style, G3 style, there are wood PGs OE & aftermarket also. inch does not interchange here at all.

some like using aftermarket grips that prohibit the selector from going into the auto position.

FN SAW grips fit and are popular for their less rakish angle.

aftermarket plastic grips are sometimes molded out of spec and bind on / inhibit movement of trigger return plunger assembly.

-BUTTSTOCKS.

~$20-up

quite a few of these to choose from. inch does not interchange here at all. early widespread metric was wood with metal buttplate (some w/trapdoors, others w/o) and butted up to rear of lower receiver. not too good. so they added a ferrule to the stock there. those are referred to as types b & c respectively.

later came rubber butt-padded, synthetic 'humpback' stocks to be had in regular or long lengths.

the Austrians, in addition to some small # of wood stocks early on, used a straight-combed synthetic stock and rubber buttpad unique to their StG58. many users report a face-slapping sensation when using these stocks and are helped by refitment with a humpback style.

here are some metric butts, L-R

Izzy light barrel, StG, Imbel, SA XL

Izzy light barrel (no trapdoor on plate), Turk 'B' w/trapdoor for G1, Belgian 'C' w/trapdoor

-CARRY HANDLES.

-CARRY HANDLES.

there is some old and repro wood around but plastic abounds inch & metric. flat top w/finger-groove is L1A1 style,

i think black is Brit & green is Aussie.

radial grooved on short wire is G1 / StG style, maybe others.

Imbel & others used a longer-wired, sort of ambi-finger-groove design.

-CHARGING HANDLE.

-CHARGING HANDLE.

$30-60

most all metrics had handles with fixed knobs made of synthetic material.

notable exceptions are the G1's aluminum knob, and the folding 'para' handle.

US made items can be readily had in folding steel or fixed steel or alloy AFAIK.

charging hanlde style and the

locking levers (horizontal vs. vertical) which open the action on a central joint pin assembly are two more items of individual preference.

below is the fixed knob with vertical lever

and the folding knob w/ horizontal lever.

i believe all inch had folding / horizontal configuration.

-UPPER RECEIVER.

$250+ for a century, 100/100s more for entreprise, DSA and the exotic imports.

the once-ubiquitous (&$189) imbel receivers can no longer be imported and are going for $500 or more. i just gave .6k for a DSA L1A1!

DCI is o-o-p but had made some nice runs of t1s, another, more recent run maybe not so nice?? no 1st hand there...i have 3 early ones in 20K range which are pretty dang nice. closer to DSA than CAI if ya know what i mean.

-there are type 1, 2 and 3 metric receivers. this has to do with the external profile at the end of the receiver's machining.

for all intents and purposes this is a matter of aesthetic preference (2 is best IMO) and availability.

reportedly the type 1 was supplanted by the t2 with a reinforced or rather an un-lightened area as compared to t1 near the recoil lug to possibly mitigate cracking in that area from sustained rapid firing. the t3 is a simplification

of the design of the receiver without all the graceful looking external cuts of the preceeding versions.

inch receivers are closest in metric terms to the t1 but were all different unto themselves with regard to external profiles i believe.

DCI t1

i have no t2, here's a lifted image from DSA, isn't it pretty!?!

imbel t3

Brit L1A1.............

the horror! :skull:

DSA Australian L1A1

-LOWER RECEIVER.

-LOWER RECEIVER.

stripped import lowers $25-up US made ~$100 &up for DSA's fancy AR-sighted or picatinny-topped models. also steel or alloy available in some models i believe. i am a BIG fan of the DSA alloy

lower in conjunction with an 18" or so barrel for a handy and well-balanced carbine.

lowers can be classed 1 2 or 3 also and that difference is seen on the lower's recoil plate where a profile is cut to match the profile of the upper receiver's rear end. so let your upper type guide you here or don't care & mix & match. it's only a visual mismatch. and only then if a FAL guy's looking....yes, ok it bothers me & i don't abide it but neither would i jeer at another's!

the following pics of the recoil plates were lifted from a post by

Rooster on the FALFiles

type 1

type2

type3

and here's what it's like when they don't match....the horror! :skull:

there are of course exceptions to everything! for instance IIRC the SA's made a "t1.5" lower @ Pretoria with a mix of the 1&2 radii on the recoil plate...but 1,2,3 are the bulk of what you'll see.

-SELECTORS don't interchange between inch & metric unless you grind on the inch selector or remove the stop pin on the metric lower which interferes. the L1A1 has an enlarged pad that is very nice and helps maintain grip while actuating it. a worthwile endeavor IMO for a metric rifle. DSA sells an ambi versions also.

metric in the pic immediately below, inch after that..

while we're at these particular pics, go back and look closer at the above rilfes'

-REAR SIGHTS the pic above shows inch rear sight, above that a standard metric.

as an assembly (with base) these interchange inch/metric. the (taller) Israeli aperture will fit a metric base.

hooded rear apertures are also available. the inch (&Indian) sights fold. there are also (rarish) multiple-aperture inch sights.

ear-protected, 2 position folding leaf sights are common to (metric) para rifles. aftermarket versions are available with tritium.

para rear sight:

-HAMMER, TRIGGER, SEAR.

-HAMMER, TRIGGER, SEAR.

$65-up for the 3pc set. hardly ever function as well as the OEM parts. several manufacturers.

2 sets DSA and 1 FSE i've had were fine if heavy, 1 cai hammer/sear set was total crap.

my jard match trigger feels amazing but that rifle's still in testing / building phase.

no interchanging with inch here.

some originals had chrome plated engagement point which is nice. G1 i think, maybe others.

-MAGAZINES

$1+***

mag bodies, followers and floorplates all count towards 922r. currently only floorplates seem available. there were followers but not recently produced it seems. pretty much all undamaged military mags are 'good'. the alloy 'para' mags are nice and light, if perhaps a bit less robust than the steel counterparts. there was limited usage / production also of straight bodied 30 round metric mags.

also to be found are converted-for-metric-use (or not) L4A1 30rd bren mags. mnay deride their use as intended for a top feed.

1 i have converted from DSA has worked fine for me each time out.

metric (SA) left, converted bren right

-MAG RELEASE

-MAG RELEASE addressed above

inch

clockwise from top left are inch, metric, Israeli (my fav by far) & a tapco "Holland":

-BHO LEVER

-BHO LEVER addressed above

inch on left:

-note the metric BHO has a 'wide foot'. there are also (earlier) metrics with a narrow foot,

and the Izzy variant which has a hole drilled through the tab that extends up off the foot. no pic sorry...

how about differences between the para and standard metric?

here's a typical fixed stock type.

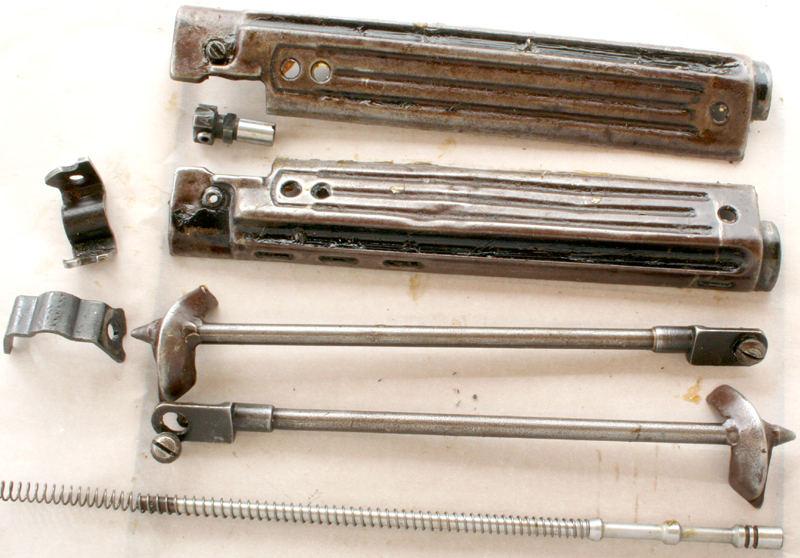

note the 'rat-tail' fixed to the bolt carrier. as the bolt & carrier travel rearward in the receiver body, rear tip of tail at "A" is driven into the return spring plunger through a hole in the lower receiver at "B" which compresses the springs in the tube inside the buttstock.

the non-para topcover, for lack of better description, is open on fore and aft ends. with the action open the bolt & carrier can be withdrawn to the rear with the cover remaining in place.

for the stock to fold, the return springs are relocated to a recess atop the para carrier.

the para topcover has a plate at it's rear to which a guide rod for the return springs is fixed. at the fore end of the cover there is a lip that hangs down into the interior of the cover a bit so that it catches the front top edge of the carrier, trapping the B/BC/topcover together so you pull the whole assembly out together.

the lip at the front of the cover requires a counterbore to be cut inside the receiver at the gas piston hole, unless you're one who would grind the lip off.

{can't find my para-cut receiver pic yet...}

the plate at the rear of the para topcover requires a clearance cut on the lower's recoil plate that is larger than on non-para lowers.

para:

non-para recoil plate:

a start........

indicates applicable "922r(ubbish) compliance part" candidates, followed by approximate cost of a US made item

indicates applicable "922r(ubbish) compliance part" candidates, followed by approximate cost of a US made item