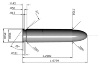

230RN

2A was "political" when it was first adopted.

"At the moment of firing (likely by a hammer swinging into a recess in the bottom of the bolt) the bolt recoils a short distance (2 mm?) before coming up short because of the flaps in the recesses, but that short movement sends the traveler on its way."

That seems to be the fly in the ointment. Allowing the bolt to come back ~0.080" while the cartridge is at almost peak pressure is almost guaranteed to rupture the now-unsupported portion of the brass case.

While a lot of guns have a small portion of the case unsupported in the chamber, the web of the case is thick at this point and the brass will hold the pressure. This is fine unless something else goes wrong, like a barrel obstruction or an overloaded case.

Garand, in his design(s) for what came to be the M1 Rifle, took a lot of trouble to avoid this unsupported area because it had been a source of "accidents" in prior designs, such as the Mauser and Springfield-type bolt rifles.

So now, unless I'm reading your descriptions incorrectly, you're going to allow the rear end of the case to stretch out 2 mm or ~0.080" while the front end is still grabbing the chamber walls. And your first description only talked about 1 mm (~0.040") of bolt withdrawal, which to my eye, looked like a recipe for disaster in the first place --see my previous post on this.

Might be barely OK for a low-pressure cartridge like a shotgun shell, but for high-intensity pistol and rifle rounds (which run up to 50 or 60 thousand "psi")... I don't think so. You might take note of the fact that the very high pressure 5.56 NATO round which grew out of the lower-pressure .223 Remington round, has had this portion of the brass case thickened substantially... even though both rounds will chamber and fire in the .223 chambers.

And just for "mental scaling" purposes, you might also take note of the fact that if the .30-06 had to be fired in a straight blowback action, the breech block would have to weigh about 27 pounds.

I strongly recommend you read Hatcher's Notebook, especially the chapter on the strength of military rifles and the one on headspace.

Again, all this if I am not misreading/misunderstanding your descriptions. The closest I can come to understanding or conceptualizing your idea is with one of Garand's original experimental designs, where the primer was allowed to set back in the case in order to unlock the bolt. This idea was abandoned by Mr. Garand.

Terry, 230RN

That seems to be the fly in the ointment. Allowing the bolt to come back ~0.080" while the cartridge is at almost peak pressure is almost guaranteed to rupture the now-unsupported portion of the brass case.

While a lot of guns have a small portion of the case unsupported in the chamber, the web of the case is thick at this point and the brass will hold the pressure. This is fine unless something else goes wrong, like a barrel obstruction or an overloaded case.

Garand, in his design(s) for what came to be the M1 Rifle, took a lot of trouble to avoid this unsupported area because it had been a source of "accidents" in prior designs, such as the Mauser and Springfield-type bolt rifles.

So now, unless I'm reading your descriptions incorrectly, you're going to allow the rear end of the case to stretch out 2 mm or ~0.080" while the front end is still grabbing the chamber walls. And your first description only talked about 1 mm (~0.040") of bolt withdrawal, which to my eye, looked like a recipe for disaster in the first place --see my previous post on this.

Might be barely OK for a low-pressure cartridge like a shotgun shell, but for high-intensity pistol and rifle rounds (which run up to 50 or 60 thousand "psi")... I don't think so. You might take note of the fact that the very high pressure 5.56 NATO round which grew out of the lower-pressure .223 Remington round, has had this portion of the brass case thickened substantially... even though both rounds will chamber and fire in the .223 chambers.

And just for "mental scaling" purposes, you might also take note of the fact that if the .30-06 had to be fired in a straight blowback action, the breech block would have to weigh about 27 pounds.

I strongly recommend you read Hatcher's Notebook, especially the chapter on the strength of military rifles and the one on headspace.

Again, all this if I am not misreading/misunderstanding your descriptions. The closest I can come to understanding or conceptualizing your idea is with one of Garand's original experimental designs, where the primer was allowed to set back in the case in order to unlock the bolt. This idea was abandoned by Mr. Garand.

Terry, 230RN

Last edited: