...realize that PSI and CUP are not exactly linear in their relationship, but they're not opposites either.

Excluding Varget from a recommended list...due to its "Higher (chamber) pressure " seems a bit silly

I do not debate that the Hodgdon site (and SAAMI itself for that matter) has higher pressure limits for tested loads.** And I do agree that CUP and psi are related (but not equal). I also agree that chamber pressure per se, is not the limiting factor in a Garand-type action. But that is not the point in any of this.

The OP

is using an M1A, not a bolt action. A combination of chamber and port pressure/gas impulse (not simple pressure) is at work here. I will near always recommend a powder combination in those actions that has port pressure

combined with powder weights "in the IMR4895 regime," AND total case fill, AND near (not

totally complete) powder burn, AND the lowest chamber pressure.

There are at least six powders listed above that fit that that combination of requirements-- producing anywhere from 2,000-5,000 psi less pressure than VARGET -- for that 175gr bullet at that velocity. It's a fairly simple choice where to start at that point.

~~~~~~~~~~~~~~~~~~~~~~

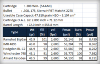

**The poster notes that CUP and psi are not equal, and so they aren't. But they tend to become proportional when pressures approach the SAAMI maxes of 52kCUP/62kpsi. That translates to:

Hodgdon MAX

H4895 Max 42.7gr. 2647 49,000 CUP

--> at least 58,400psi

Varget Max 45.0gr. 2690 48,600 CUP

--> at least 58,000psi

Again, I'd simply not recommend operating that close to MAX if there are other options.