J-Bar

Member

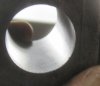

I've heard that a side-by-side shotgun's chambers can be polished out with a brake cylinder hone on a hand drill...makes it easier and faster to dump empty hulls during a cowboy action match.

Have any of you done this, any dangers, recommendations? I have an occasional hull hang up and it's frustrating, but don't want to risk ruining a good gun.

Thanks.

Have any of you done this, any dangers, recommendations? I have an occasional hull hang up and it's frustrating, but don't want to risk ruining a good gun.

Thanks.

.

.