I posted about this shotgun in the Firearms Research forum to get some history. I'll post a range report in the shotgun forum.

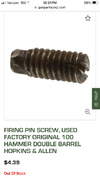

But I have a non-urgent repair issue. This is a sidelock exposed hammer shotgun that uses a firing pin retaining screw to hold the firing pin in place in lieu of a firing pin bushing. The screws are loose enough to rotate but apparently the ends of the screws are both peened from the hammer strikes on the firing pin and the pins striking the screws and the screws can only be screwed out a small amount before the peened portion interferes with the threads and prevents the screw from being unscrewed further. Here are a couple of pictures of the arrangement and parts involved:

Screw in place

Firing Pin

Firing Pin Spring

The only thing I know to do is to keep trying to turn the screw to back it out but not hard enough to damage the screw slot anymore than it is. But to use enough Force to try and swage (probably the wrong term) the deformed part into the threads.

Do you see another way to coax these screws out without destroying them? Is continuing to try to unsscrew the hoping to swabe the peened part a waste of time? I'm patient and if it will eventually work I'll try. You never e, i might come back in 5 years reporting success.

The only other option is to drill it out completely. Even though they are listed at Numrich, they are not available. So drilling them out isn't really an option. They currently work but I would like to be able to remove them for service in the future. I suppose they could be turned from raw material if they had to be drilled out for service in the future.

Im open for suggestions.

But I have a non-urgent repair issue. This is a sidelock exposed hammer shotgun that uses a firing pin retaining screw to hold the firing pin in place in lieu of a firing pin bushing. The screws are loose enough to rotate but apparently the ends of the screws are both peened from the hammer strikes on the firing pin and the pins striking the screws and the screws can only be screwed out a small amount before the peened portion interferes with the threads and prevents the screw from being unscrewed further. Here are a couple of pictures of the arrangement and parts involved:

Screw in place

Firing Pin

Firing Pin Spring

The only thing I know to do is to keep trying to turn the screw to back it out but not hard enough to damage the screw slot anymore than it is. But to use enough Force to try and swage (probably the wrong term) the deformed part into the threads.

Do you see another way to coax these screws out without destroying them? Is continuing to try to unsscrew the hoping to swabe the peened part a waste of time? I'm patient and if it will eventually work I'll try. You never e, i might come back in 5 years reporting success.

The only other option is to drill it out completely. Even though they are listed at Numrich, they are not available. So drilling them out isn't really an option. They currently work but I would like to be able to remove them for service in the future. I suppose they could be turned from raw material if they had to be drilled out for service in the future.

Im open for suggestions.

Last edited: