Jamie C.

Member

Anybody used one'a these?

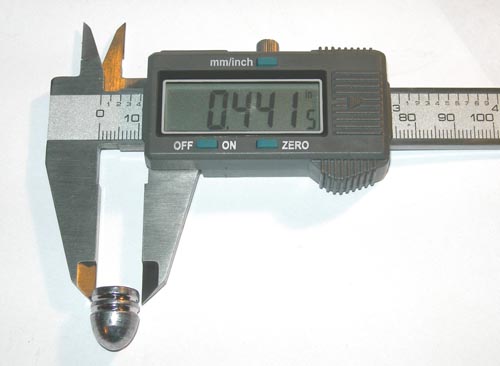

Conical Bullet Mold

At .450 dia., I wonder if the bullets wouldn't be too small for an Uberti's chambers... But on the other hand, I'm thinking of using it to make paper cartridges, so the layer of paper might make for a snug fit. Or the paper could get shaved off during loading and be of no help at all.

Any thoughts on this? Should I just stick with round ball?

J.C.

Conical Bullet Mold

At .450 dia., I wonder if the bullets wouldn't be too small for an Uberti's chambers... But on the other hand, I'm thinking of using it to make paper cartridges, so the layer of paper might make for a snug fit. Or the paper could get shaved off during loading and be of no help at all.

Any thoughts on this? Should I just stick with round ball?

J.C.