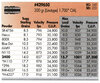

Searching for low pressure loads in 44 Magnum. The goal is to make a loads using lead bullets 265 up to 300 grains, to get about 1100 fps from revolver with 6.5"-7.5" barrel, but pressure up to 23 000 CUP. I looked on internet but the only load I found close to my wish is on Hodgdon website https://www.hodgdonreloading.com/reloading-data-center?rdc=true&type=53 :

270 GR. SPR GDSP, powder HS-6, 11 grains, 1036 fps (barrel 8.275"), 22 200 CUP

Since this is jacketed bullet, but fired from 8.275" long barrel, I would expect that lead bullet 265 grains will do about the same from revolver with 7.5" barrel.

However, when going to 45 Colt (Ruger, Freedom Arms & T/C only) loads, also from Hodgdon, things are getting very interesting:

325 GR. CPB LFN PB, powder H110, starting load 21.0 grains, loaded round OAL 1.680", 1109 fps (barrel 7.250"),18 100 CUP

335 GR. CPB LFN GC, powder H110, starting load 20.5 grains, loaded round OAL 1.680", 1109 fps (barrel 7.250"),19 200 CUP

Now, if we scale down noted 45 (,453) bullets on 44 (.431), and powder charges, we are getting these results:

45-325 scaled to; 44, 294 grains, powder H110, 19.0 grains, loaded round OAL 1.680" (DO NOT USE, for reference only)

45-335 scaled to; 44, 303 grains, powder H110, 18.56 grains, loaded round OAL 1.680" (DO NOT USE, for reference only)

When checking closest 44 bullet and and powder charge:

300 GR. HDY XTP, powder H110, starting load 18.0 grains, loaded round OAL 1.600", 1266 fps (barrel 8.275"), 35 100 CUP

As you could see, just straight scaling down powder charges is something that shouldn't be done. Obviously, higher friction of jacketed bullet and shorter loaded round OAL make a big difference in pressure and velocity.

Going to Hodgdon website and checking 41 Magnum, 265 grains:

265 GR. WLNGC, powder H110, starting load 19.5 grains, loaded round OAL 1.710", 1410 fps (barrel 10.125"), 24 400 CUP

Scaling up 41-265 bullet and its powder charge, we are getting:

41-265 scaled to; 44, 290 grains, powder H110, 20.79 grains, loaded round OAL 1.710" (DO NOT USE, for reference only).

Obviously, using one caliber and its loads, scale them up or down for another caliber, is a very risky, rather dangerous proposal. ONLY TESTED LOADS SHOULD BE USED. However, this little exercise indicates that that even loads at moderate pressure range 20 000-23 000 CUP could lunch bit heavier bullets at a reasonable velocity..

On the end, I wish that powder and bullet manufacturers standardize their load testing procedures using setup that will properly simulate revolver, with about .004" gap and barrel 6.5".

I would appreciate your opinion and eventual correction.

270 GR. SPR GDSP, powder HS-6, 11 grains, 1036 fps (barrel 8.275"), 22 200 CUP

Since this is jacketed bullet, but fired from 8.275" long barrel, I would expect that lead bullet 265 grains will do about the same from revolver with 7.5" barrel.

However, when going to 45 Colt (Ruger, Freedom Arms & T/C only) loads, also from Hodgdon, things are getting very interesting:

325 GR. CPB LFN PB, powder H110, starting load 21.0 grains, loaded round OAL 1.680", 1109 fps (barrel 7.250"),18 100 CUP

335 GR. CPB LFN GC, powder H110, starting load 20.5 grains, loaded round OAL 1.680", 1109 fps (barrel 7.250"),19 200 CUP

Now, if we scale down noted 45 (,453) bullets on 44 (.431), and powder charges, we are getting these results:

45-325 scaled to; 44, 294 grains, powder H110, 19.0 grains, loaded round OAL 1.680" (DO NOT USE, for reference only)

45-335 scaled to; 44, 303 grains, powder H110, 18.56 grains, loaded round OAL 1.680" (DO NOT USE, for reference only)

When checking closest 44 bullet and and powder charge:

300 GR. HDY XTP, powder H110, starting load 18.0 grains, loaded round OAL 1.600", 1266 fps (barrel 8.275"), 35 100 CUP

As you could see, just straight scaling down powder charges is something that shouldn't be done. Obviously, higher friction of jacketed bullet and shorter loaded round OAL make a big difference in pressure and velocity.

Going to Hodgdon website and checking 41 Magnum, 265 grains:

265 GR. WLNGC, powder H110, starting load 19.5 grains, loaded round OAL 1.710", 1410 fps (barrel 10.125"), 24 400 CUP

Scaling up 41-265 bullet and its powder charge, we are getting:

41-265 scaled to; 44, 290 grains, powder H110, 20.79 grains, loaded round OAL 1.710" (DO NOT USE, for reference only).

Obviously, using one caliber and its loads, scale them up or down for another caliber, is a very risky, rather dangerous proposal. ONLY TESTED LOADS SHOULD BE USED. However, this little exercise indicates that that even loads at moderate pressure range 20 000-23 000 CUP could lunch bit heavier bullets at a reasonable velocity..

On the end, I wish that powder and bullet manufacturers standardize their load testing procedures using setup that will properly simulate revolver, with about .004" gap and barrel 6.5".

I would appreciate your opinion and eventual correction.