If you use maximum loads, where the temperature of the day might blow the primer, than using mixed cases is bad. I use mid pressure loads in my 30-06's and 308 Win's, loads that were used by many target shooters in many guns, on many days, and I don't have issues with changes in brass, primers, or even make of bullets. What I mean by bullets are the 168 match bullets, Sierra, Speer, Hornady, Nosler, I could load any of those bullets and not experience any pressure or function problems, and could mix primers and brass. I would shoot all the same primer and charge, brass varying, and out to 300 yards, I can hold the NRA ten ring at 300 yards.

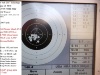

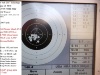

These rifles are sporting rifles in 30-06, not bench or match rifles. I think these groups are fine, considering the brass was not sorted by headstamp. So I had R-P, W/W, Nosler, Hornady, LC different years. maybe some Greek, etc. Shoots fine

If I can shoot 17 shots within 6 inches at 300 yards with a pre WW2 era M70, I am not worried about case type.

by the way, the Weaver 4X on the 1939 M70 is a very old Weaver, I think it is an El Paso Weaver, so old I was not interested in touching the elevation or windage knobs, as old scopes may move the group a graduation, or not, and not until a couple of shots later when the reticle jumps! Once I found this rifle shoots very well, I installed a newer scope. The optics on that old Weaver are not the best, it was very gray in over cast conditions.

I have shot better groups in NRA Highpower Competition out to 300 yards with my 223 AR15's. I had baggies of brass, all reloaded the same number of times, same primer, but mixed headstamp, and I would load them all with the same bullet and powder charge, and shoot cleans sitting RF and prone RF out to 300 yards.

However, I always felt that at 600 yards, it was best practice to use same headstamp, same everything else. Proving at 600 yards that changes in one component or not makes a difference, requires access to a 600 yard range, and lots of range time. Which I don't have. My F Class buds are shooting groups way inside anything I am doing with hunting rifles, and they are absolutely obsessive compulsive with their reloading practices. However that sport, like bench rest, has greatly reduced the human factor, which is the greatest source of error in hand held weapons. When shooters put a rifle rest, on a 600 lb concrete bench, and the only thing they touch is the trigger, they are eliminating sources of error, such as heart beat, flinch, rigidity of holding the weapon, etc. So they are seeing things with their loads that are within my hold with a sling, or a non target rifle.

Generally, it is better to load a lot of ammunition and shoot it, then spending that time, creating ammunition following bench rest reloading practices. One shooting bud, who won several 1000 yard events at Perry (sling shooter), he bought good brass (Lapau) used CCI Benchrest primers, loaded the cases, used a good bullet, and shot the stuff. And that was good enough for a National Championship.