Vettepilot555

Member

- Joined

- Mar 17, 2018

- Messages

- 138

I'm guessing this might have been covered in the past, but I couldn't find an answer to my exact question, so here goes... apologies if it's a stupid question and/or has been thoroughly covered before.

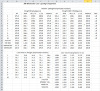

So I just bought a batch of 308 range brass, and have sorted it by headstamp. I ended up with some Federal, PPU, Lake City, etc., in batches of 40 to 80 or more. No problem there; just work up a load for each headstamp.

But I also ended up with around 200 or so in assorted headstamps. Some I have 3 of, some 8, some 5, etc., etc. What is the best way to deal with those??

Hypothetical case:

Let's say you have Federal brass, and it averages (xx) internal water volume, and you work up a safe, yet fast load for it. Could you then safely take a brand "X" headstamped case, that measures the SAME internal volume, and load it the same as the Federal??

What are acceptable safe internal volume tolerances in 30 cal brass?

Thanks for any and all insights,

Vettepilot

So I just bought a batch of 308 range brass, and have sorted it by headstamp. I ended up with some Federal, PPU, Lake City, etc., in batches of 40 to 80 or more. No problem there; just work up a load for each headstamp.

But I also ended up with around 200 or so in assorted headstamps. Some I have 3 of, some 8, some 5, etc., etc. What is the best way to deal with those??

Hypothetical case:

Let's say you have Federal brass, and it averages (xx) internal water volume, and you work up a safe, yet fast load for it. Could you then safely take a brand "X" headstamped case, that measures the SAME internal volume, and load it the same as the Federal??

What are acceptable safe internal volume tolerances in 30 cal brass?

Thanks for any and all insights,

Vettepilot