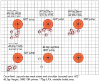

It was overcast and fairly calm this morning so I shot the 10 rounds that I put together yesterday. The first shot of the morning was the impact near 12 o'clock on the left target. The next four rounds appeared to make one ragged hole and I was excited since I thought I'd shot one of the best .308 Win groups of my life only to discover that it was larger than the 5-shot group shown previously. However, it's clearly a great combination for this rifle pushing the bullet about .005" into the lands in front of 44.1gr of Varget. Maybe .0025" into the lands would be the best load given the "touch" and .005" jam results. That would give some margin for less than perfect handloads. As far as groups go, anything better than about 0.5 moa will be luck on my part since I feel that I'm at the limit of my abilities here, particularly given the weight of the rifle and my shooting set up. I'm going to shoot a couple more groups just like the one below left (maybe .0025" jam) to confirm that everything is good, followed by the same COAL but +/- 0.3gr to see what it looks like. If the bracketing loads look decent I'll move onto the 175gr LRX load. So far I'm very pleased with how few rounds I've shot to get to this point and "jamming" the bullet into the lands is something I'll be investigating with other rifles/loads.

The bloody LabRadar has been acting up despite formatting the SD card so I only got one velocity reading which was 2,701 fps. I need to tighten up some of my reloading skills such as bumping the shoulder back. I mentioned earlier that the chamber is tight i.e. the bolt has some resistance closing on a GO gage, but the fired cases are coming out at about .0015" over minimum SAAMI. I was trying to bump the shoulder back .002" but ended up with more like .004" to .005" of bump. It's amazing how much case lube and press velocity affect shoulder bump.

The bloody LabRadar has been acting up despite formatting the SD card so I only got one velocity reading which was 2,701 fps. I need to tighten up some of my reloading skills such as bumping the shoulder back. I mentioned earlier that the chamber is tight i.e. the bolt has some resistance closing on a GO gage, but the fired cases are coming out at about .0015" over minimum SAAMI. I was trying to bump the shoulder back .002" but ended up with more like .004" to .005" of bump. It's amazing how much case lube and press velocity affect shoulder bump.

Last edited: