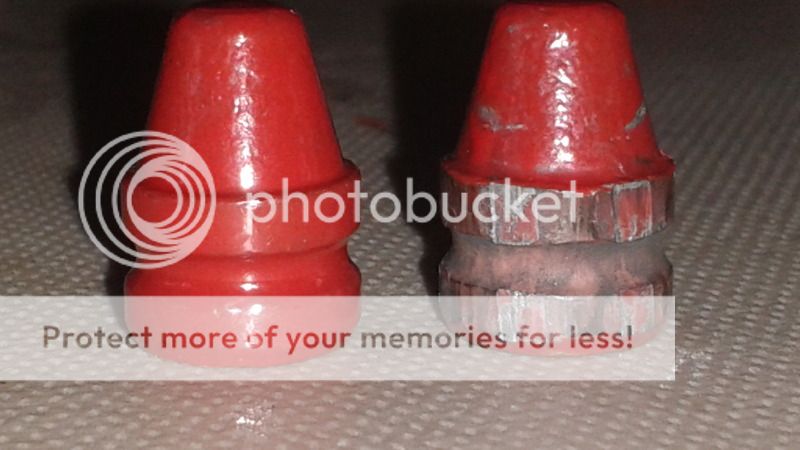

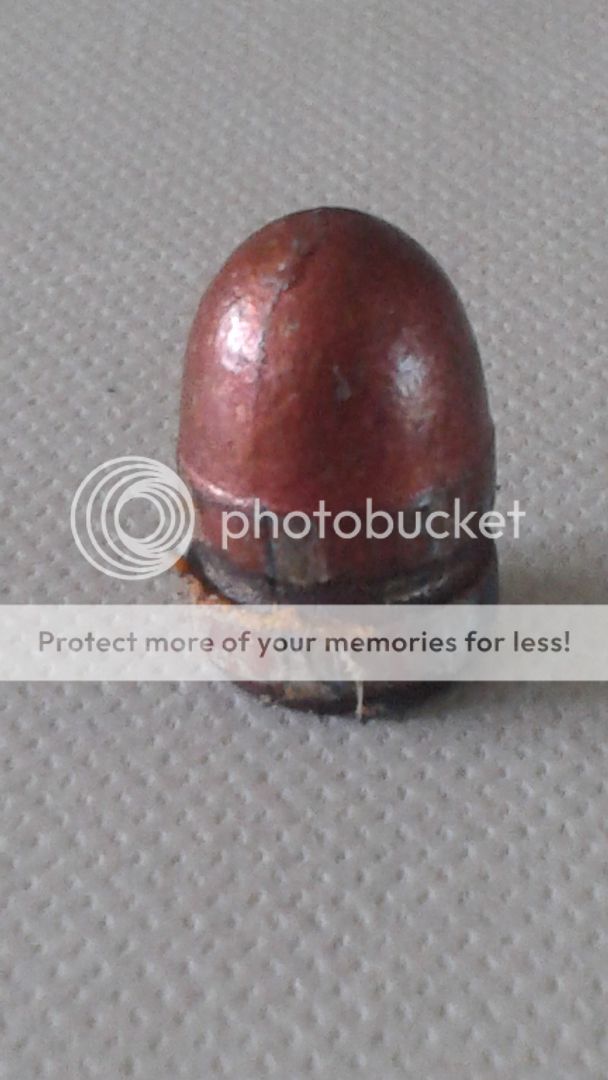

my missouri bullet co. order arrived this morning. 125 grain swc hi-tec 9mm .356" dia. i just had to work up a load for the glock 19 and try it out!

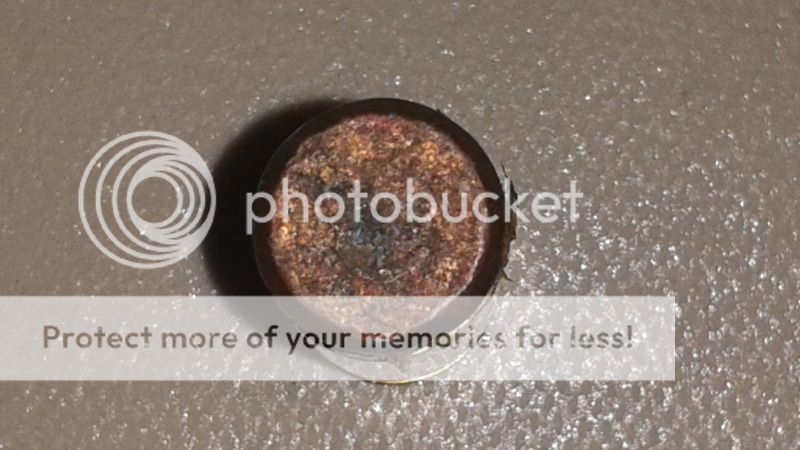

this also became a case length test. i sorted the win cases by length and will see if it makes a difference in group size.

anyway, i'm happy to have a practice load for the glock w/ the stock barrel. i've already made up ten more @ 1.083" c.o.l. and will run them over the chrony tomorrow. so far no leading in the stock barrel.

murf

this also became a case length test. i sorted the win cases by length and will see if it makes a difference in group size.

anyway, i'm happy to have a practice load for the glock w/ the stock barrel. i've already made up ten more @ 1.083" c.o.l. and will run them over the chrony tomorrow. so far no leading in the stock barrel.

murf