berettaprofessor

Member

Thought those here would be interested in this little set of reloads. Based on your advice in this thread, I loaded 30 of the brand-spanking new Starline Valkyrie today without annealing....or doing anything else...cases were properly sized already at 1.589-1.591 and necks looked great so I just dived in. The bullet used was a Hornady 88grain ELD. But I wanted to answer some questions about runout and the Frankford Ultimate Precision Die set, so I loaded 10 with a Lee die seating firmly in one stroke, 10 with a Lee die seating partway, turning 1/4th turn, and then seating completely, and 10 with the Frankford Arsenal Ultimate Seating Die I recently purchased and a 224 insert. Then I hauled out the Hornady concentricity gauge and measured runout in all 30, ran them through a Lee LCD to crimp very lightly, and then measured runout again (runout measured in 1000's of an inch).

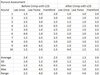

Results below:

I don't know about you, but looking at those numbers, I'd say that it doesn't make any difference if I use a Lee or Frankford die, or if I seat the bullet in one stroke or partially seat it, turn it, and seat it the rest of the way. The Lee FCD also doesn't seem to have made a difference in runout. Those averages, SD's, and ranges are all so close they're probably within my measurement error.

I suppose the only caveat here is that an average runout of 2-2.6 thousands is not very high to begin with. A higher initial runout might still be affected by seating twice or by using the FCD.

Now I wish I'd loaded another 10 with the RCBS 224 Valkyrie Seating Die I have.....Next time.

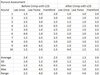

Results below:

I don't know about you, but looking at those numbers, I'd say that it doesn't make any difference if I use a Lee or Frankford die, or if I seat the bullet in one stroke or partially seat it, turn it, and seat it the rest of the way. The Lee FCD also doesn't seem to have made a difference in runout. Those averages, SD's, and ranges are all so close they're probably within my measurement error.

I suppose the only caveat here is that an average runout of 2-2.6 thousands is not very high to begin with. A higher initial runout might still be affected by seating twice or by using the FCD.

Now I wish I'd loaded another 10 with the RCBS 224 Valkyrie Seating Die I have.....Next time.