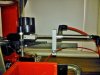

This in my initial test for fit and function. It went much better than I had expected, nothing broke and function was as intended (albeit a little more vigorous then expected).

I never really cared for the case feed mechanism on the Load Master even though It works and I have no problems getting it to function. I always felt it made operating the press feel heavier than need be.

Realistically, the pneumatics make the operation of the lever feel about 15% lighter.

https://www.youtube.com/watch?v=2MjppGMY7XE

I never really cared for the case feed mechanism on the Load Master even though It works and I have no problems getting it to function. I always felt it made operating the press feel heavier than need be.

Realistically, the pneumatics make the operation of the lever feel about 15% lighter.

https://www.youtube.com/watch?v=2MjppGMY7XE

Attachments

Last edited: