Looks like I am getting into shooting Webley .455 revolvers again, after more than 15 years. I already have appropriate hollow base bullet mold from MP-Molds https://www.mp-molds.com/product/455-webley-mk2-hollow-base-4-cavity-mold/ . Now, the issue is brass. I even tried to organize group buy on another forum, asking dealer to contact Starline in order to manufacture longer Mk I brass, but no avail. Instead, Starline started making shorter Mk II brass. To make long story short, I was making my own Mk I brass, starting first with 45 Colt case and later switched to 45 Schofield. I liked more later one because inside reaming not required, and it has bit larger rim dia than 45 Colt case.

While checking chambers in the cylinder of my Webley Mk VI, I found that I could insert 45 Colt case trimmed on 1.100", see https://www.shootersforum.com/threads/45-schofield-loads-for-webley-mk-vi.24147/ . If that revolver was modified, I don't know, would like to hear from you that have Webley Mk VI, did you find the same.

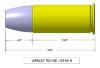

Looking further, I found that OAL of loaded .455 Mk I round is even trifle longer than 45 Schofield one:

When looked loading data on Hodgdon website, I was quite surprised to see that using 250 grain bullet, velocities from 45 Schofield are quite above standard velocities from .455 Webley:

From https://www.hodgdonreloading.com/reloading-data-center .-

As you could see, only one max load with Universal (6.3 grains) is above max. pressure of 6 tons (per square foot), aka 13 440 PSI, for Webley Mk VI

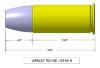

And that gave me idea, "wait if". If I am lucky and get that revolver, I might look for another cylinder, modify it and make loaded round as bellow, using shortened mold (now 250 grains) for 455", 265 gr HB bullet, and trimmed 45 Schofield case. I called this round.455 Mk 6. Going this way, I can use wider range of loads for 45 Schofield, tested by Hodgdon and other reputable companies.

Since Webley Mk VI cylinder has face to face 1.500" length, this loaded round will have .040" clearance from the front face.

Please take a look, I would appreciate any opinion or suggestion, thanks.

P.S. I helped manufacturer to recreate bullet mold for .455 Webley, so if somebody wants mold for same bullet I am proposing, I am confident that they could easily modify existing mold for .455-265-HB.

While checking chambers in the cylinder of my Webley Mk VI, I found that I could insert 45 Colt case trimmed on 1.100", see https://www.shootersforum.com/threads/45-schofield-loads-for-webley-mk-vi.24147/ . If that revolver was modified, I don't know, would like to hear from you that have Webley Mk VI, did you find the same.

Looking further, I found that OAL of loaded .455 Mk I round is even trifle longer than 45 Schofield one:

When looked loading data on Hodgdon website, I was quite surprised to see that using 250 grain bullet, velocities from 45 Schofield are quite above standard velocities from .455 Webley:

From https://www.hodgdonreloading.com/reloading-data-center .-

As you could see, only one max load with Universal (6.3 grains) is above max. pressure of 6 tons (per square foot), aka 13 440 PSI, for Webley Mk VI

And that gave me idea, "wait if". If I am lucky and get that revolver, I might look for another cylinder, modify it and make loaded round as bellow, using shortened mold (now 250 grains) for 455", 265 gr HB bullet, and trimmed 45 Schofield case. I called this round.455 Mk 6. Going this way, I can use wider range of loads for 45 Schofield, tested by Hodgdon and other reputable companies.

Since Webley Mk VI cylinder has face to face 1.500" length, this loaded round will have .040" clearance from the front face.

Please take a look, I would appreciate any opinion or suggestion, thanks.

P.S. I helped manufacturer to recreate bullet mold for .455 Webley, so if somebody wants mold for same bullet I am proposing, I am confident that they could easily modify existing mold for .455-265-HB.

Last edited: