You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HS6 Data Differences in 357 Magnum

- Thread starter DMW1116

- Start date

243winxb

Member

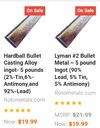

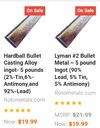

Some Lymans have gas checks on the base. Lyman alloy is #2. More tin then Hard Ball alloy.

Rotometal alloys

Basic Rules for Hardening Lead-

For every 1% additional tin, Brinell hardness increases 0.3.

For every 1% additional antimony, Brinell hardness increases 0.9.

For a simple equation,

Brinell = 8.60 (Antimonial Lead) + ( 0.29 * Tin ) + ( 0.92 * Antimony )

Rotometal alloys

Basic Rules for Hardening Lead-

For every 1% additional tin, Brinell hardness increases 0.3.

For every 1% additional antimony, Brinell hardness increases 0.9.

For a simple equation,

Brinell = 8.60 (Antimonial Lead) + ( 0.29 * Tin ) + ( 0.92 * Antimony )

Last edited:

243winxb

Member

Quote:

From my old Lyman manual.

While antimony is used to harden the bullet, the mixture of tin is critical, for while antimony mixes with lead in its molten state, it will not remain mixed when it solidifies. If tin were not added, we would have pure antimony crystals surrounded by pure lead. A bullet of this type , while it feels hard , would certainly lead the bore and eliminate all potential for accuracy.. In a lead-tin-antimony mixture, the antimony crystals will be present just the same, but they will be imbedded in a lead-tin mixutre. As the bullet cools the tin will form around the antimony-lead keeping your bullets from leading the bore.

The bullets I'm using don't seem to lead the barrel. They're 158 grain SWC NLG from Missouri Bullet Company. They are Hi-Tech coated. For a full power load, I use a charge of 13.6 grains of 2400. These bullets mic at 0.360", so I'm sure they seal the bore well. However, the Hodgden data is for a generic LSWC with HS6, so that is probably the reason for the difference. I've shot these bullets through the charge range in the Lyman Cast Manual using HS6 as well, which goes up to about 9 or maybe more. 2400 was more accurate, but I'm running out and thought about trying HS6 again.

243winxb

Member

Not because of pressure. Hodgdon @15,500 CUP. When SAAMI maximum is 45,000 CUP.Hodgdens data stops at 7 grains in 357 Magnum with 158 grain SWC cast bullets

243winxb

Member

P Flados

Member

When load data was developed, there could have been a number of different reasons to stop with pressures below max.

One big change in recent years is the use of coatings on cast bullets. I have guns that do not want to be pushed past 38 Sp power with traditional lube, but are OK to ful magnum with coated bullets.

Another point to consider is that I see a lot of data posted in cup instead of psi. The cup data is usually very old data. I usually try to avoid relying on cup data. Most Lyman data is old cup data.

And then there is COAL and bullet length. Seating depth can make a big difference.

I ran a 1.590" COAL load with a 0.665" long Lee 158 over 10 gr of HS6 through Quickload and got just over SAAMI MAP. Then I ran the 0.660" long Lyman 155 with the same COAL and charge but I changed the weight to 158. I got just under MAP. Note that the Lee bullet is seated 0.005" deeper than the Lyman.

One big change in recent years is the use of coatings on cast bullets. I have guns that do not want to be pushed past 38 Sp power with traditional lube, but are OK to ful magnum with coated bullets.

Another point to consider is that I see a lot of data posted in cup instead of psi. The cup data is usually very old data. I usually try to avoid relying on cup data. Most Lyman data is old cup data.

And then there is COAL and bullet length. Seating depth can make a big difference.

I ran a 1.590" COAL load with a 0.665" long Lee 158 over 10 gr of HS6 through Quickload and got just over SAAMI MAP. Then I ran the 0.660" long Lyman 155 with the same COAL and charge but I changed the weight to 158. I got just under MAP. Note that the Lee bullet is seated 0.005" deeper than the Lyman.

Last edited:

Alaskamike

Member

- Joined

- Jun 19, 2020

- Messages

- 229

I really dislike when we use the term "lead bullets". There is a whole world of difference between soft, pure lead swaged bullets, and cast lead alloy bullets. To use the term "lead bullets" implies that we treat them equally, when nothing could be further from the truth.

I routinely push cast bullets to velocities typical of jacketed bullets, with no leading whatsoever in any of my revolvers, or my Rossi 92 carbine with a 20" barrel. In fact, some of my carbine loads probably come very close to 50kpsi. I'm not even using exotic alloys like Linotype--I simply use old clip on wheel weight alloy with a little added tin. I would never do this with pure lead, swaged bullets.

The Hodgdon data is almost certainly for dead soft pure lead swaged bullets. Unfortunately, they simply call it "158 GR. CAS LSWC" which really tells us nothing. I will assume that their use of "CAS" here means Cowboy Action Shooting, but that's purely an assumption. With cast alloy bullets you can push them much harder than 15,500 psi using HS6.

This really warrants a call to Hodgdon to find out whether they used a pure lead swaged bullet, or a cast lead alloy bullet, or if there is some other reason they limited their published data to 15,500 CUP.

I routinely push cast bullets to velocities typical of jacketed bullets, with no leading whatsoever in any of my revolvers, or my Rossi 92 carbine with a 20" barrel. In fact, some of my carbine loads probably come very close to 50kpsi. I'm not even using exotic alloys like Linotype--I simply use old clip on wheel weight alloy with a little added tin. I would never do this with pure lead, swaged bullets.

The Hodgdon data is almost certainly for dead soft pure lead swaged bullets. Unfortunately, they simply call it "158 GR. CAS LSWC" which really tells us nothing. I will assume that their use of "CAS" here means Cowboy Action Shooting, but that's purely an assumption. With cast alloy bullets you can push them much harder than 15,500 psi using HS6.

This really warrants a call to Hodgdon to find out whether they used a pure lead swaged bullet, or a cast lead alloy bullet, or if there is some other reason they limited their published data to 15,500 CUP.

GeoDudeFlorida

Member

- Joined

- Dec 1, 2020

- Messages

- 11,067

Excellent points. Hornady and Speer both still sell swaged antimonial lead bullets. They are exceptionally accurate and work very well for small game with the right loads.I really dislike when we use the term "lead bullets". There is a whole world of difference between soft, pure lead swaged bullets, and cast lead alloy bullets. To use the term "lead bullets" implies that we treat them equally, when nothing could be further from the truth.

I routinely push cast bullets to velocities typical of jacketed bullets, with no leading whatsoever in any of my revolvers, or my Rossi 92 carbine with a 20" barrel. In fact, some of my carbine loads probably come very close to 50kpsi. I'm not even using exotic alloys like Linotype--I simply use old clip on wheel weight alloy with a little added tin. I would never do this with pure lead, swaged bullets.

The Hodgdon data is almost certainly for dead soft pure lead swaged bullets. Unfortunately, they simply call it "158 GR. CAS LSWC" which really tells us nothing. I will assume that their use of "CAS" here means Cowboy Action Shooting, but that's purely an assumption. With cast alloy bullets you can push them much harder than 15,500 psi using HS6.

This really warrants a call to Hodgdon to find out whether they used a pure lead swaged bullet, or a cast lead alloy bullet, or if there is some other reason they limited their published data to 15,500 CUP.

Hooda Thunkit

Member

The right loads - I. E: at the right pressure levels.They are exceptionally accurate and work very well for small game with the right loads.

I routinely push right past the "lead" bullet levels with HS6. I am in the middle of jacketed data with both 357 and 44 Mag using HS6, and this with a cast alloy around 10-11 BnH.

I don't know why Hodgdon stops at such a low pressure with cast data, but they have been doing just that for decades.

GeoDudeFlorida

Member

- Joined

- Dec 1, 2020

- Messages

- 11,067

Only they can answer. I do know why Lyman is higher and Hornady is lower but I have no idea which testing labs Hodgdon uses or if they use data from more than one source. I’ve never been all that sold on Hodgdon as a primary source of information. They’re a distributor, not a primary contractor or manufacturer.The right loads - I. E: at the right pressure levels.

I routinely push right past the "lead" bullet levels with HS6. I am in the middle of jacketed data with both 357 and 44 Mag using HS6, and this with a cast alloy around 10-11 BnH.

I don't know why Hodgdon stops at such a low pressure with cast data, but they have been doing just that for decades.

AJC1

Member

Good Ole Elmer and I think bhn 12 is good for full 35k max loads and beyond... 13.7 grains of #9 is full power for a 158 cast...

Last edited:

GeoDudeFlorida

Member

- Joined

- Dec 1, 2020

- Messages

- 11,067

Sad truth is No.9 is now harder to find and costs about as much as the competition. I have seen HS6 on the shelf in the last month; I haven’t seen No.9 in over a year.Good Ole Elmer and I think bhn 12 is good for full 35k mak loads and beyond... 13.7 grains of #9 is full power for a 158 cast...

Soonerpesek

Member

Damn...................I've got a 8lber that I have tried to rehome....................!!Sad truth is No.9 is now harder to find and costs about as much as the competition. I have seen HS6 on the shelf in the last month; I haven’t seen No.9 in over a year.

AJC1

Member

I shifted to blue dot so I hadent noticed. I only have about half a pound, I guess my plan to try them all is working as I will spend time testing and loading what I can get cheap. Have you tried sw heavy pistol?Sad truth is No.9 is now harder to find and costs about as much as the competition. I have seen HS6 on the shelf in the last month; I haven’t seen No.9 in over a year.

GeoDudeFlorida

Member

- Joined

- Dec 1, 2020

- Messages

- 11,067

Not yet. I’m powder poor right now.I shifted to blue dot so I hadent noticed. I only have about half a pound, I guess my plan to try them all is working as I will spend time testing and loading what I can get cheap. Have you tried sw heavy pistol?

41 Mag

Member

I guess I am in with the others on the question of just what Hodgdon used, and would call them to verify. I load mostly cast for all of my handguns and most are of the magnum variety from 357 thru 454. I routinely load into the higher pressure areas with an alloy that runs around an 11 BHN on average with no ill effects. I have however also found that just because you can run one alloy with one load of a specific powder, it doesn't always work across the board. I have cleaned out several leaded up barrels, which were for no other reason, caused by the change in my alloy. I pretty much knew it was going to happen but had to try it and see anyway. It was going from a known working load with a certain alloy, to a bit softer, then a bit softer to see where the limit was. Kinda like working up a load only from a different angle. Nothing dramatic like going from straight linotype to pure, just changing the batch up a little at a time to see what the limit would be.

I use HS-6 almost exclusively for my 45 Colt and for a couple of other caliber loads, as well as AA-9, and 296. My most used 357 load is a MP 359-640 160gr cast HP over 13gr's of AA-9 and second to that is the Lyman 358-429 SWC over the same charge with the same 11 BHN alloy mentioned above. I have used HS-6, 2400, and 296, but they just didn't give me the same accuracy as Accurate did.

I use HS-6 almost exclusively for my 45 Colt and for a couple of other caliber loads, as well as AA-9, and 296. My most used 357 load is a MP 359-640 160gr cast HP over 13gr's of AA-9 and second to that is the Lyman 358-429 SWC over the same charge with the same 11 BHN alloy mentioned above. I have used HS-6, 2400, and 296, but they just didn't give me the same accuracy as Accurate did.

2ndtimer

Member

I used a bit of HS-6 a couple decades ago but it was supplanted by Unique, which was followed by Accurate No. 5 for “all purpose” handloads in .38/.357, 9mm, .45 ACP and mid range .44 Mag. The No. 5 was replaced by Power Pistol during one of the scarcity panics, and my current go to is BE-86 for my “universal” handgun powder. (I actually have two pounds of Hodgdon Universal still tucked away in reserveI guess I am in with the others on the question of just what Hodgdon used, and would call them to verify. I load mostly cast for all of my handguns and most are of the magnum variety from 357 thru 454. I routinely load into the higher pressure areas with an alloy that runs around an 11 BHN on average with no ill effects. I have however also found that just because you can run one alloy with one load of a specific powder, it doesn't always work across the board. I have cleaned out several leaded up barrels, which were for no other reason, caused by the change in my alloy. I pretty much knew it was going to happen but had to try it and see anyway. It was going from a known working load with a certain alloy, to a bit softer, then a bit softer to see where the limit was. Kinda like working up a load only from a different angle. Nothing dramatic like going from straight linotype to pure, just changing the batch up a little at a time to see what the limit would be.

I use HS-6 almost exclusively for my 45 Colt and for a couple of other caliber loads, as well as AA-9, and 296. My most used 357 load is a MP 359-640 160gr cast HP over 13gr's of AA-9 and second to that is the Lyman 358-429 SWC over the same charge with the same 11 BHN alloy mentioned above. I have used HS-6, 2400, and 296, but they just didn't give me the same accuracy as Accurate did.

I, too, like Accurate No. 9 for full .357 Mag loads, although I plan on trying Enforcer down the road if No. 9 is scarce.

I never got around to casting my own bullets, but have shot a bunch of them from various producers. My current favorite is T&B Bullets who sells some really nice coated cast bullets. https://tbbullets.com/

LV Gun

Member

I do the same thing with LLA and I buy all my bullets I just leave the lube in the bullets and put LLA right over it , this works extremely well and actually keeps your barrels clean and literally free of lead.It sure does.

That’s why I started using liquid alox as a supplemental lube on all my lead bullets.

In most cases it works like magic to prevent leading, especially with softer swaged bullets.

Similar threads

- Replies

- 28

- Views

- 840

- Replies

- 7

- Views

- 898

- Replies

- 11

- Views

- 432

- Replies

- 28

- Views

- 760

- Replies

- 15

- Views

- 2K