I prefer leather but want to try and make some "shells" for a IWB holster. Not sure if it is worth making a press and buying the extra stuff I will need.

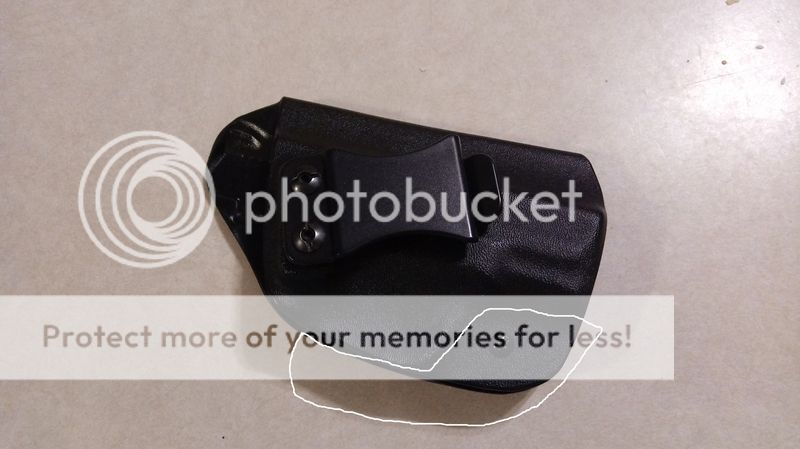

I have a really nice IWB hybrid holster (ComTac) (kinda like CrossBreed) that has a leather backing and uses kydex shells for the gun. It is is very well made, The shells just screw on .

I do not want to buy all the shells as I am not real sure what gun I want to carry (IWB) I am more of a pocket or outside the waistband with a long shirt. Here in Florida, IWB holster are not real comfortable (at least for me)

I would like to try and make some shells for different guns (they sell them for around $26.00 each)

I did some research, watched videos etc and seems like I can give it a try. I have a old toaster oven and can make a press.

I have all kinds of tools for trimming, cutting, buffing etc.

I will need a good infrared thermometer to check the kydex temp and some of the foam for the press. Heck, if I screw up I can reheat it,and try again.

Where is a good source for the kydex and what thickness is recommended? Also, if you have any good links that would help. Some of the ones I watched well, they were kinda Bubba'ish!.

Thanks

I have a really nice IWB hybrid holster (ComTac) (kinda like CrossBreed) that has a leather backing and uses kydex shells for the gun. It is is very well made, The shells just screw on .

I do not want to buy all the shells as I am not real sure what gun I want to carry (IWB) I am more of a pocket or outside the waistband with a long shirt. Here in Florida, IWB holster are not real comfortable (at least for me)

I would like to try and make some shells for different guns (they sell them for around $26.00 each)

I did some research, watched videos etc and seems like I can give it a try. I have a old toaster oven and can make a press.

I have all kinds of tools for trimming, cutting, buffing etc.

I will need a good infrared thermometer to check the kydex temp and some of the foam for the press. Heck, if I screw up I can reheat it,and try again.

Where is a good source for the kydex and what thickness is recommended? Also, if you have any good links that would help. Some of the ones I watched well, they were kinda Bubba'ish!.

Thanks