ssmith1187

Member

- Joined

- Dec 14, 2011

- Messages

- 23

Good evening!!

I am currently in the process of developing some hunting loads for my Ruger M77 Mark II rifle chambered in .30-06. I am not new to reloading but I am new to rifle cartridge reloading.

I am to the point in the process where I am determining the optimal bullet seating depth using a Hornady O.A.L. Gauge and Hornady Bullet Comparator.

As a point of reference I measured a Federal Fusion 165 grain factory loaded cartridge and came up with an ogive measurement of 2.603 inches.

I am using a dowel inserted into the muzzle end of the barrel and “feathering” the bullet back and forth to determine the point when it contacts the rifling in the barrel. Once this has been determined I then lock the thumb screw on my O.A.L. gauge and remove it from the chamber of my rifle and take the measurement using my bullet comparator.

The bullets I am interested in potentially developing a hunting load for are (also listed is the ogive measurement and the difference between it and the reference cartridge measurement):

Barnes 168 grain TSX: 2.719 inches (+.116 inches longer than the reference cartridge)

Berger 168 grain VLD – Hunting: 2.689 inches (+.086 inches longer than the reference cartridge)

Hornady 165 grain SST: 2.683 inches (+.080 inches longer than the reference cartridge)

Nosler 165 grain Ballistic Tip: 2.729 inches (+.126 inches longer than the reference cartridge)

Sierra 165 grain GK Spitzer Boat Tail: 2.733 inches (+.130 inches longer than the reference cartridge)

Speer 165 grain Boat Tail Soft Point: 2.724 inches (+.121 inches longer than the reference cartridge)

I understand I am comparing apples (a generic factory loaded cartridge) to oranges (potential hunting loads) but the difference seems to be larger than I would have expected. Even visually the new loads seem much longer than the factory loaded cartridge. I understand that factory loaded cartridges need to be manufactured to fit countless chambers, but I would not have thought the measurements would have been that different.

Hornady recommends a free-travel of between .020 to .040 inches. So taking the longest measurement (Sierra GK) of 2.733 inches and subtracting .040 inches (maximum recommended free-travel) gives me a bullet seat depth of 2.693 inches. That is still .09 inches longer than the reference cartridge.

Am I placing too much stock in the reference cartridge measurement? Should I not even be thinking in terms of that measurement or should I just be concerned with the my bullet comparator is telling me?

Thank you,

Steve

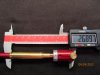

Attached are a few photos showing:

#1) The length of my reference cartridge

#2) The length of the Berger 168 grain VLD – Hunting cartridge

#3) The visual difference between the two

#4) The current seating depth of the bullets listed above (in that order from left to right). Note, the current seating depth does NOT take into account the additional .020 to .040 inch adjustment.

I am currently in the process of developing some hunting loads for my Ruger M77 Mark II rifle chambered in .30-06. I am not new to reloading but I am new to rifle cartridge reloading.

I am to the point in the process where I am determining the optimal bullet seating depth using a Hornady O.A.L. Gauge and Hornady Bullet Comparator.

As a point of reference I measured a Federal Fusion 165 grain factory loaded cartridge and came up with an ogive measurement of 2.603 inches.

I am using a dowel inserted into the muzzle end of the barrel and “feathering” the bullet back and forth to determine the point when it contacts the rifling in the barrel. Once this has been determined I then lock the thumb screw on my O.A.L. gauge and remove it from the chamber of my rifle and take the measurement using my bullet comparator.

The bullets I am interested in potentially developing a hunting load for are (also listed is the ogive measurement and the difference between it and the reference cartridge measurement):

Barnes 168 grain TSX: 2.719 inches (+.116 inches longer than the reference cartridge)

Berger 168 grain VLD – Hunting: 2.689 inches (+.086 inches longer than the reference cartridge)

Hornady 165 grain SST: 2.683 inches (+.080 inches longer than the reference cartridge)

Nosler 165 grain Ballistic Tip: 2.729 inches (+.126 inches longer than the reference cartridge)

Sierra 165 grain GK Spitzer Boat Tail: 2.733 inches (+.130 inches longer than the reference cartridge)

Speer 165 grain Boat Tail Soft Point: 2.724 inches (+.121 inches longer than the reference cartridge)

I understand I am comparing apples (a generic factory loaded cartridge) to oranges (potential hunting loads) but the difference seems to be larger than I would have expected. Even visually the new loads seem much longer than the factory loaded cartridge. I understand that factory loaded cartridges need to be manufactured to fit countless chambers, but I would not have thought the measurements would have been that different.

Hornady recommends a free-travel of between .020 to .040 inches. So taking the longest measurement (Sierra GK) of 2.733 inches and subtracting .040 inches (maximum recommended free-travel) gives me a bullet seat depth of 2.693 inches. That is still .09 inches longer than the reference cartridge.

Am I placing too much stock in the reference cartridge measurement? Should I not even be thinking in terms of that measurement or should I just be concerned with the my bullet comparator is telling me?

Thank you,

Steve

Attached are a few photos showing:

#1) The length of my reference cartridge

#2) The length of the Berger 168 grain VLD – Hunting cartridge

#3) The visual difference between the two

#4) The current seating depth of the bullets listed above (in that order from left to right). Note, the current seating depth does NOT take into account the additional .020 to .040 inch adjustment.