The forcing cone cracks on the barrel of these guns due to the machined thinning of the barrel to fit the longer .357 cylinder in the frame sized for .38 spl.

Howdy Again

With all due respect, the machined thinning of the forcing cone on K frame revolvers has nothing to do with the length of a 357 Magnum cylinder. As I said in an earlier post, S&W has been putting a relief cut on the underside of the forcing cone of K frame revolvers since dinosaurs roamed the earth, long before the existence of the 357 Magnum cartridge. It has to do with the diameter of the gas ring, that portion of the cylinder that protrudes beyond the front face of the cylinder. The diameter of the gas ring required that in order for the cylinder to close, a clearance cut had to be made on the underside of the forcing cone. Otherwise the cylinder would not close. The amount of material removed in the clearance cut has varied over the years, but every K frame Smith I own, except one, has a clearance cut on the underside of the forcing cone.

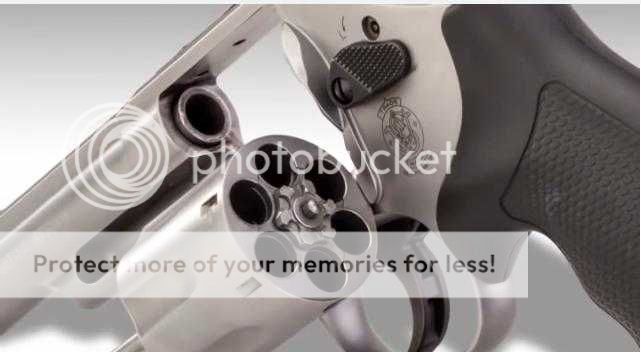

Here are some representative photos of a few in my collection of K frames.

38 M&P made in 1920. The relief cut is difficult to see with the less than ideal lighting of this photo, but it is there.

38 M&P made in 1939. Clearly visible relief cut.

K-38 made in 1957

Clearance cut on a 357 Magnum Model 13-2 made in 1979. Clearly, there has been more material removed from the underside of the forcing cone on this revolver than any of the others and the lower portion or the forcing cone is visibly thinner. That is because the gas ring is larger in diameter than any or the others, .435 in diameter. Most of the other gas rings are running around .421 - .423 in diameter. So clearly, with that much material removed from the forcing cone, combined with the power of the 357 Magnum cartridge, cracked forcing cones could become an issue.

Here is the exception to the rule, a 38 M&P Model 1899, made in 1899. Why no relief cut? The gas ring on this revolver is pretty big, .437 in diameter. The answer is the shank of the barrel is thinner, so there was no need for a clearance cut. That football shaped relief on the underside of the top strap is not flame cutting. That is the old Black Powder relief cut that S&W and other revolver makers used to put on the underside of the top strap. Don't forget, the 38 Special cartridge started out as a Black Powder cartridge. The relief cut was put there in the belief that it would provide a place for Black Powder fouling to accumulate without building up sufficiently to bind the cylinder. Eventually the BP relief cut was reduced and finally eliminated.

All this goes to show how the Smith and Wesson hand Ejector design evolved over time. The K frame M&P did not spring fully developed from the minds of the designers at S&W in 1899. Like most manufactured products, it was tweaked and modified over time. With the K frame 357 Magnum revolvers the splitting forcing cone problem became a new issue not seen with the older 38 Special K frames. The ultimate solution was the development of the L frame, a little bit taller, with a little bit more room for the gas ring without needing a clearance cut under the forcing cone.