OS/N

Member

- Joined

- Nov 2, 2023

- Messages

- 246

With the ever increasing cost of primers, powder, and bullets, I have put more effort and time into producing accurate cast loads.

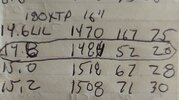

Here are a few of the later and time tested loads I use for lever carbine and also the revolver. Velocity listed is for carbine which has a 10:1 twist liner. Powder type is given but not the charge - as always work up your own charge weight with the use of a trusted published manual.

200GC FP - 1450 Lil'Gun T

180 TCGC Sil - 1650 Lil'Gun T

158 Lee RFP GC added - 1850 Li'Gun H/T

150 RN GC added - 1780 W296 T

125 2R GC added - 2300 W296 H

(H = hunting use: T = target)

When loading the same bullets (less the 200) for the revolver, I do not use the above listed powders. For handgun a mid range burn powder is used and charge determined by impact to point of aim. Powders used in revolver: Longshot, True Blue, Blue Dot, or as always 2400.

Alloy - Lyman #2

Lube - Lyman Moly

Sized - same as groove in carbine and same as cyl throat for revolvers (within reason).

Sure others are doing or considering cast bullets. I refuse to pay what bullets go for now days. Scrounged lead is what it is but purchased alloy still will run close to 6 to 9 cents a piece depending on source and bullet weight.

Here are a few of the later and time tested loads I use for lever carbine and also the revolver. Velocity listed is for carbine which has a 10:1 twist liner. Powder type is given but not the charge - as always work up your own charge weight with the use of a trusted published manual.

200GC FP - 1450 Lil'Gun T

180 TCGC Sil - 1650 Lil'Gun T

158 Lee RFP GC added - 1850 Li'Gun H/T

150 RN GC added - 1780 W296 T

125 2R GC added - 2300 W296 H

(H = hunting use: T = target)

When loading the same bullets (less the 200) for the revolver, I do not use the above listed powders. For handgun a mid range burn powder is used and charge determined by impact to point of aim. Powders used in revolver: Longshot, True Blue, Blue Dot, or as always 2400.

Alloy - Lyman #2

Lube - Lyman Moly

Sized - same as groove in carbine and same as cyl throat for revolvers (within reason).

Sure others are doing or considering cast bullets. I refuse to pay what bullets go for now days. Scrounged lead is what it is but purchased alloy still will run close to 6 to 9 cents a piece depending on source and bullet weight.

Last edited: