What you are seeing in the variation of data between Lyman and Lee books is a difference in philosophy in load goals and bullet hardness.

Lyman's philosophy is that if you want to shoot magnum cartridges their data should reflect a magnum loading. The Linotype alloy is a hard bullet alloy with a 22 BNH hardness. This type alloy can be shot to magnum velocity levels at a higher pressure near the SAAMI CUP max of 46,000. In fact the extra hard alloys will usually lead badly at lower pressure.

Lee doesn't develop load data for their bullet. They do publish a book using data obtained from other sources, mostly the powder companies which is why their data matches that published by Hodgdon. Hodgdons philosophy on lead bullets is that they are for use in Cowboy action shooting that is restricted to low velocity loading at lower pressure. This is why their d"ata and Lee's data is so much lower for the same bullet weight

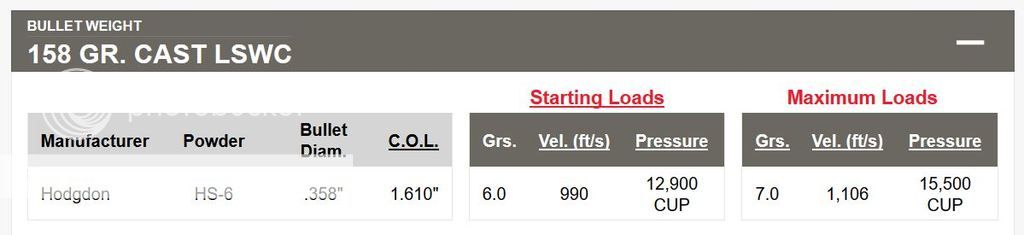

The data below is from online Hodgdon data. Note the pressures at the maximum load is much less than maximum SAAMI 46,000 CUP's. Also note the actual velocity from a revolver will be quite a bit less as Hodgdon uses a 10" test barrel putting real world velocities likely less than 900 fps.

If your bullets are at 18 BNH you can use the Lyman data for load development. If they are the typical Cowboy hardness of 12 BNH you should use the data found in the LEE and the on line Hodgdon sources.