I have run into a few examples where a compressed load with a ball powder in a straight wall case resulted in Quickload (QL) result significantly over measured pressures.

However, further investigation says that this example is mostly a "bad inputs" issue.

I checked a Federal 357 case and found it took 27.4 gr of H110 to fill the case. I then plugged in 27.4 gr H110 into QL and set the OAL for zero seating depth. Quickload said that this was a 108.2% fill instead of the measured 100% fill.

I then did the water capacity test and found the Fed case to hold 27.0 gr of water. The QL default was 25.5 gr.

I changed the QL water capacity to 27 gr and the fill percentage went to 102.6%.

This means that the case capacity and the powder density were both off, and the combined error was significant. With cases capacity tweaked to 27.7 gr of water, the percent fill is effectively fixed (27.4 gr of H110 gives 100% fill at 0 seating depth).

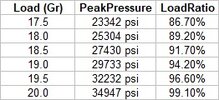

With the above "fudged" input, the max allowed SAAMI pressure of 35,000 psi is reached at 99.9% fill with 21.4 gr of H110. This is much closer to the Hodgdon data. Lot to lot variations for powder batches and variations in case capacities can easily explain this magnitude of difference in results.

As far as running a compressed load of lets say 104% of H110, I would not expect to see an "signs of pressure" in any stout gun. The resultant pressure is likely to be close to 45000 psi. I load a lot of different cartridges with essentially the same case diameter in my TC Contender. If you fire a 55,000 psi 357 mag load in a Contender, what "sign of pressure" would you expect. Primer appearance will vary from brand to brand, but some amount of "flat primer" will show up at anything over 30,000 psi and perforations are not expected until probably over 65,000 psi. Sticky extraction is not expected until probably over 60,000 psi.

Given the above, I would recommend avoiding any compressed loads of H110 under a 125 gr or bigger bullet unless both there is a real need and the ammo is only going to be used in a "stout" gun. Using a percent fill as a "double check" for a max charge really helps deal with making sure that everything "matches up" with expectations.