CMV

Member

Loading mixed HS brass. Running into problems with oversize ID at the mouth.

WIN, FED, CCI, & others are fine, but I had some TZZ & RP that were giving me issues. .451 bullets going into the case all the way down with just my thumb. Some would go a good way in & stop, but after loading, a firm push against the bench would make them move in another .005 - .015.

After a while I noticed that there was no resistance on the expander die - it felt like I was running the press with no die at all. On those, sometimes the bullet would go all the way in with just my fingers, others it just went in a little like a normally expanded case. Most cases I felt the expander die contacting the brass - it was just these certain ones.

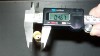

Most all the TZZ 85 HS was that way. About 1/4 of the RP. Measuring the ID of some, they were .4505 - .451. Double checking the Hornady HAP & they were always .451.

Thought maybe I could save some with the Lee FCD. Some would still push in & others would not.

I tried running a few through the FL sizing die a couple more times rotating the case & running again. The expander still didn't touch them.

I tried crimping the empty case, then expanding, then seating, then FCD and that didn't work and caused a couple to split.

Other than trashing the rest, is there a way to identify that upfront? I hate that I'm prepping & putting primers into cases that I can't then load - or have to take apart because there is no tension. I can sort out the TZZ HS & just trash it all since there isn't that much, but I have lots of RP mixed in with everything else.

I'm using Lee carbide dies. Would a different FL die do any better? Don't know how it would because they all have the same OD - it's the ID that's the problem which suggests the brass is particularly thin on these troublesome cases.

This mixed lot of brass was given to me (so I shouldn't complain) as 1x or 2x fired, but after seeing some RA42 headstamps I would assume there are many more firings on some of it - but a lot seemed brand new.

WIN, FED, CCI, & others are fine, but I had some TZZ & RP that were giving me issues. .451 bullets going into the case all the way down with just my thumb. Some would go a good way in & stop, but after loading, a firm push against the bench would make them move in another .005 - .015.

After a while I noticed that there was no resistance on the expander die - it felt like I was running the press with no die at all. On those, sometimes the bullet would go all the way in with just my fingers, others it just went in a little like a normally expanded case. Most cases I felt the expander die contacting the brass - it was just these certain ones.

Most all the TZZ 85 HS was that way. About 1/4 of the RP. Measuring the ID of some, they were .4505 - .451. Double checking the Hornady HAP & they were always .451.

Thought maybe I could save some with the Lee FCD. Some would still push in & others would not.

I tried running a few through the FL sizing die a couple more times rotating the case & running again. The expander still didn't touch them.

I tried crimping the empty case, then expanding, then seating, then FCD and that didn't work and caused a couple to split.

Other than trashing the rest, is there a way to identify that upfront? I hate that I'm prepping & putting primers into cases that I can't then load - or have to take apart because there is no tension. I can sort out the TZZ HS & just trash it all since there isn't that much, but I have lots of RP mixed in with everything else.

I'm using Lee carbide dies. Would a different FL die do any better? Don't know how it would because they all have the same OD - it's the ID that's the problem which suggests the brass is particularly thin on these troublesome cases.

This mixed lot of brass was given to me (so I shouldn't complain) as 1x or 2x fired, but after seeing some RA42 headstamps I would assume there are many more firings on some of it - but a lot seemed brand new.