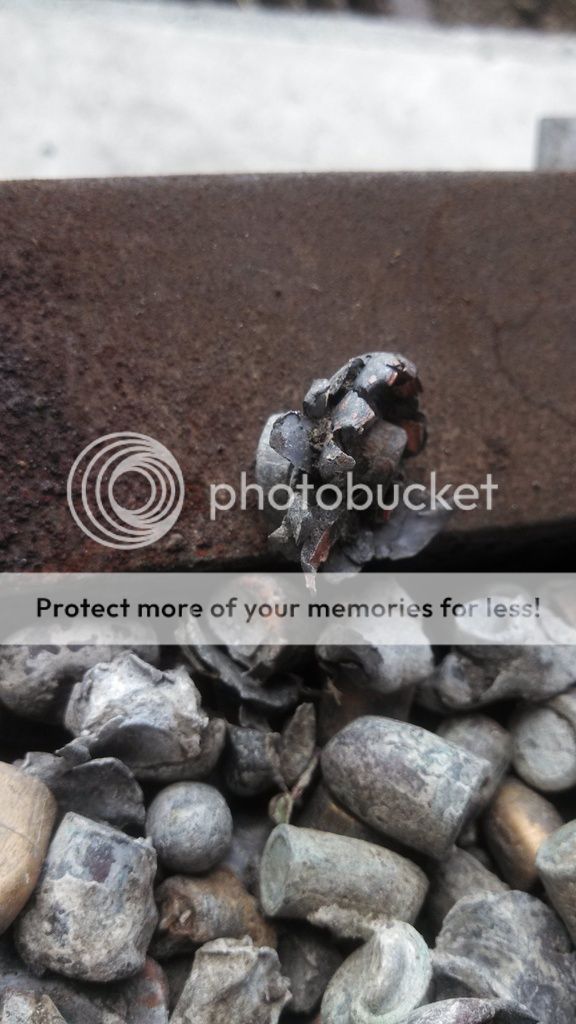

I just finished up smelting a little over 2,000 pounds of recovered bullets two months ago. About half was mined from the berms at our range, and the other half was purchased at .50 cents a pound.

Out of that, I ended up with approximately 1,600 pounds in 10 pound ingots, which is the perfect size for my 40 pound casting pot, and my 80 pound Mark 6 Bullet Master. There was just over 275 pounds of copper jackets, which I sold to the recycler for $1.80 a pound as #2 Copper, since the price of copper is down at the present time. There was also about 50 pounds of steel and copper washed jackets, and I only got .04 cents a pound for those, but at least they go back into the supply system and not into the ground.

When smelting recovered bullets, fill the pot and then turn on your heat source. This will bake the moisture out of the bullets and they'll melt down just fine. Do this outside, and use sawdust for fluxing. My pot holds about 200 pounds of bullets, but I don't like to work with over about 150 pounds at a time. Here is where I should mention to make sure the platform your heat source is mounted in is strong enough to hold that much weight. The thought of a couple hundred pounds of molten metal flowing across the floor/ground, will certainly give one pause to reflect on the results.

When adding more reclaimed bullets to the pot, you can put a layer of about an inch of sawdust on your molten alloy, and then add the bullets to the top of it. This allows the heat to bake the moisture out of the newly added bullets. There will be lots of smoke from this, but it will smell like a campfire if you don't use some odorous wood for the sawdust. Oak sawdust smells good, as does pine.

You'll need ingot molds, and the types are endless, depending on the size of your casting pot. For most home casting pots, one pound ingots are about ideal, though you can go to two pound ingots and still be ok.

I could go on and on about this subject, but this should give you an idea of how it's done. This last batch of recovered bullets yielded a BHN of 12, which is perfect for most handgun applications, and some rifle uses, too. I've pushed a 420 gr. bullet of Bhn 12 to 2,200 fps in my .45-120 Sharps without any leading, but this is because of several factors that I won't go into now, since it's off topic.

Hope this helps.

Fred