grubbylabs

Member

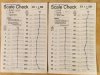

So I just got my beam scale back from Hornady. They were supposed to check it out and make sure it was weighing correctly. I was specious because I was getting different results between it and my RCBS Charge Master. The Charge Master seemed to be more along the lines of what I would suspect. I was weighing match grade bullets and the charge master said .1-.2 grain difference, so a 200 grain bullet would weigh 199.9 or 199.8 but my beam scale put the same exact bullets at 200.6 to 200.8.

So I called Hornady and they had me send it in. I got it back and it was still off. It zeros out just fine, but it is still off. So I had my wife take it to work and check it against the test weights they use in their lab at the Hospital.And sure enough, my scale is off from their weights. And it seems that the more weight you add the worse it gets. at 30 grams it was 1 full grain off. the bullets that I weighed on my Charge master came back the exact same weight. So I know at least the charge master is on.

So what beam scale do I try next?

So I called Hornady and they had me send it in. I got it back and it was still off. It zeros out just fine, but it is still off. So I had my wife take it to work and check it against the test weights they use in their lab at the Hospital.And sure enough, my scale is off from their weights. And it seems that the more weight you add the worse it gets. at 30 grams it was 1 full grain off. the bullets that I weighed on my Charge master came back the exact same weight. So I know at least the charge master is on.

So what beam scale do I try next?

Last edited: