hey all

i have just loaded my first batch of bullets, 45 apc

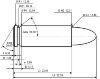

in the lynman manual they show at the beginnning of the section on 45 apc a lover alll length of 1.275 and then at the end of each load group they show an oal measurement , this measurement is less than the 1.275 at the beginning ,on my loads 200 grain led bullet the oal is 1.235

is the one they show at the beginning the maximum and the one with each group the minimum cartridge length

i set my seating depth right at 1.265

i cant find anywhere in the manual it says minimum and maximum

thanks for any help

i have just loaded my first batch of bullets, 45 apc

in the lynman manual they show at the beginnning of the section on 45 apc a lover alll length of 1.275 and then at the end of each load group they show an oal measurement , this measurement is less than the 1.275 at the beginning ,on my loads 200 grain led bullet the oal is 1.235

is the one they show at the beginning the maximum and the one with each group the minimum cartridge length

i set my seating depth right at 1.265

i cant find anywhere in the manual it says minimum and maximum

thanks for any help