You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

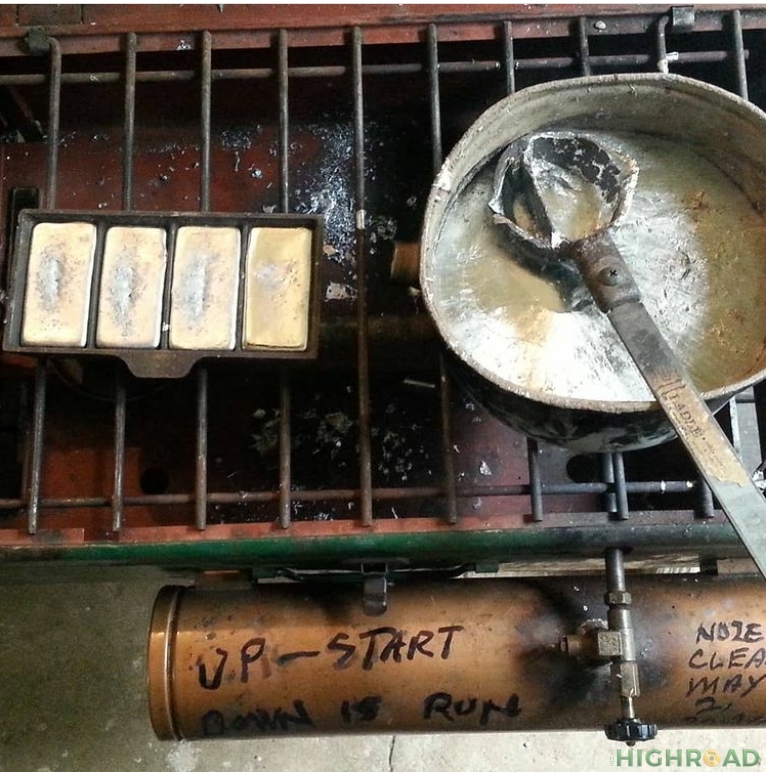

casting 12ga slugs ladle vs bottom pour

- Thread starter JO JO

- Start date

AJC1

Member

The velocity of the pour maters if your mould does not have enough material for thermal stability....casting 12ga slugs ladle vs bottom pour ?

I was talking with an old timer and he said that with big and heavy projectiles the mold will produce best results by ladle pouring has anyone found this to be true ?

Ladle pour.....

Fast/max volume flow/non-contact

...so air can escape

(trust me)

Fast/max volume flow/non-contact

...so air can escape

(trust me)

The Firing Line Forums - View Single Post - 12ga .69 Round ball load success (I think)

The Leading Online Forum for firearms Enthusiasts

thefiringline.com

Docendo Discimus

Member

- Joined

- Jun 30, 2021

- Messages

- 303

casting 12ga slugs ladle vs bottom pour ?

I was talking with an old timer and he said that with big and heavy projectiles the mold will produce best results by ladle pouring has anyone found this to be true ?

AJC and the old timer are right. Ladle is the way to go unless you have a bottom pour with a big spout and a really hot steel or brass mold.The velocity of the pour maters if your mould does not have enough material for thermal stability....

243winxb

Member

Lee 10 lb bottom pour pot used to cast Lee 12ga, 1 oz key drive slug. Pure lead , max temp.

Have not used my ladle in 40 years to fill molds. Pressure casting sometimes works better then a drop.

Have not used my ladle in 40 years to fill molds. Pressure casting sometimes works better then a drop.

For most of my sixty-five years of casting everything from .22 through 58 minies and hollow base slugs and hollow point bullets I have used a pot and ladle with the ladle in contact with the sprue hole. For me, most uniform. For gang moulds, get them hot and bottom pour. Cast 30 cal 170 grain bullets vary no more than +/- .2 grain.

(FWIW, guess how many words autocorrect told me I was spelling wrong)

(FWIW, guess how many words autocorrect told me I was spelling wrong)

nofendertom

Member

- Joined

- Sep 12, 2019

- Messages

- 1,019

I started casting Lee 1oz key drive slugs a few years ago. I use a Lee pot and a Lee ladle. This has worked for me for almost 50yrs of casting 38,44 and 45 bullets.

Last edited:

.38 Special

Member

- Joined

- Sep 15, 2006

- Messages

- 7,372

For my money, mold temperature is the critical part when casting big bullets. With a hot mold and hot alloy, I get fine results with both bottom pour and ladle. With lower temperatures, neither works especially well.

Having said that, I generally get more uniform weights when I use the ladle, especially with 500+ grain bullets. That matters quite a bit in some applications - long-range blackpowder target guns, for instance - but I'm not sure it would make any difference at all for things like shotgun slugs.

Having said that, I generally get more uniform weights when I use the ladle, especially with 500+ grain bullets. That matters quite a bit in some applications - long-range blackpowder target guns, for instance - but I'm not sure it would make any difference at all for things like shotgun slugs.

I'm going to cast the Lyman 525 slugespecially with 500+ grain bullets.

.38 Special

Member

- Joined

- Sep 15, 2006

- Messages

- 7,372

I'm going to cast the Lyman 525 slug

For shotgun slugs, I bring the alloy to 800 degrees F, dip the lower front edge of the mold into the molten lead for two minutes, and then begin casting. Sometimes the first drop will be a reject, but mostly I get good slugs right away - whether dipping or bottom pouring. Again, I get more consistent weights when I use the ladle, but for the life of me, I can't tell a difference in shooting, at least with slugs out of a smoothbore.

I probably take more care than necessary with casting slugs but in my strange mind I think that there are so many problems getting a slug from ingot to target I want to remove at least the weight variations. Can't say yet that it has made discernable improvements. At least not like with my 1954 30-06 Model 70.

Similar threads

- Replies

- 22

- Views

- 3K

- Replies

- 3

- Views

- 1K

- Replies

- 6

- Views

- 509

- Replies

- 7

- Views

- 977