Have you considered the cyl. gap? It can be loosing up to 100 fps / .001" of gap.

To test, place empty unprimed case in bottom chamber and slide a thick enough feeler gage in behind that empty to hold the cyl. ahead against the forcing cone. No gap. See how much it gains.

I would also not compress the powder at all. Bullet just sitting on settled powder. no wad for a test at least.

I would think crushing the powder as much as you have been doing is forcing the powder to burn from one end to the other of it's length in chamber by not letting the flame travel around and through the powder granules to ignite it all quicker.

roddoc,

I have to disagree with you on this. You need a refresher in Fluid Dynamics, specifically on gas flow. Go crack the books and get back to us.

A loss of 100fps/.001" is totally erroneous, where did you pull that from?

I need to look through my old files, but about 40 years ago (probably in the late 60's or early '70s) there was a good article in the American Rifleman about the effects of cylinder gap and velocity loss. This was a subject of interest at the time because of the introduction of the .22 Jet in the S&W 53. "Everyone" was convinced it was a losing velocity because of the revolver's cylinder gap. A chambered test barrel was constructed and they found there was NOT a significant loss as they expected. The author of the article set out to find just how much of a loss there was for each .001" of cylinder gap. He started with the cylinder literally butted up against the barrel face using shims and a yoke he sacrificed for the project. Then he moved it back in .001” increments until he reached .010”. He found the first .001” experienced a 3% loss in velocity. Then contrary to what anyone besides someone who understands gas flow, each additional .001” only experienced an incremental (not overall) additional 1% loss.

So if you started at 1,800 fps with zero gap you would be at 1,579 with .010” That’s a loss of 220 fps. No one in their right mind would run a revolver at “zero” so let’s extrapolate a bit and assume a “super tight” gap of .002” That means it would start at 1,728 (which is actually about right for a .22 Jet) and then end at 1,579 for a .01” gap that a loss of only 149fps or 8.6%. I have an interest in that info because I have built some improved short .22 K-Hornets on Smith revolvers, not the Kay-Chuk I had to be difficult and do it the hard way with a personal wildcat ( I was younger and more hard headed then…).

Then there are several articles that have been done using Dan Wesson revolvers because you can set the barrel gap. They have been done with the .44 mags, .357 and at least one with the .22LR. I had a “kit” model 15-V and I played around with it in the ‘80s. That’s what taught me the practical application of cylinder gap.

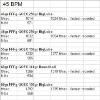

Here is an article from Shooting Times, June 1983 about a well done test with a Dan Wesson 22-VH. You will see the results were once again different than what the wives’ tales recount and even what the author expected.

ADDED 4/20

I couldn't find my older American Rifleman magazines but this report was originally published on THR a couple of years ago.

Notice how little it changes per .001". The .38 spl low pressure loads are what we should be looking at for BP, it is right in the velocities and corresponding pressures we discuss on this forum. The high pressure table is there to provide another set of data points. Notice how this correlates well with what I remembered from the American Rifleman article and correlates with the Dan Wesson test above.

So, Clembert I wouldn’t worry too much about your cylinder gap. The problem is the amount of BP and the barrel length to burn it in. You’ve run up against the wall of diminishing returns even with the fastest granulation that would be safe in that revolver. I will recommend that you compress the “tar” out of your loads and apply a very heavy crimp. Fill your case vibrate it down and add more if necessary, a drop tube might be called for. Then make sure you get at least 1/8” compression (more if you can get it).

BP is a very inefficient propellant, you get 60% uncombusted materials even with an optimized barrel length for the charge. So, only 40% of the charge is potentially converted into propelling gases and that once again assumes you have a tube long enough to take advantage of it. At some point you’re just spewing burning and unburned particles out the muzzle. It makes for “purty” night shooting and some hair singing results…

Try and compress it more and see if you can squeeze a bit more velocity out of it. Crimp it hard to help the pressure build a bit.

You seem like a bright guy, what is your training in? I have several friends who are engineers out of Clemson.

Regards,

Mako

whenever he shoots those 40 grain .45 Colts. I told him they were "fun" loads.

whenever he shoots those 40 grain .45 Colts. I told him they were "fun" loads.

whenever he shoots those 40 grain .45 Colts. I told him they were "fun" loads.

whenever he shoots those 40 grain .45 Colts. I told him they were "fun" loads.