A Must Read for the Civilian M1 Rifle Owner:

The M1 Garand Gas Cycle

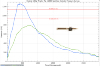

To interpret the data provided, we will need to define the gas cycle. The gas cycle on the M1 Garand can be broken up into several distinct stages. Each stage affects how the pressure in the gas cylinder is changing. The Gas cylinder and operating rod assembly on the M1 are lossy. That is to say, gas is always flowing past the gas piston when the pressure in the gas cylinder is greater than the pressure outside of the gas cylinder. The following stages will deal with gas flowing into the gas cylinder. A graph of a typical gas cycle when using M2 ball (HXP) is shown in Figure 2.

Stage 0: The first stage consists of the bullet traveling up the barrel, compressing the air in front of it. The bullet moves up the barrel faster than the gas can escape from it. This causes the pressure to rises in the barrel. This stage ends when the bullet has moved up the barrel and is blocking the gas port. The compressive force of the bullet traveling up the barrel combined with gas blow-by will pressurize the gas cylinder to approximately 10psi. This initial pressure transient is what we use to start the data acquisition process.

Stage 1: This stage is defined as the bullet having moved forward of the gas port, but is still in the barrel. This stage is responsible for the highest rate of change of pressure over time (dp/dt). However, it is also the shortest of the stages, lasting approximately 46 microseconds.

Stage 2: The bulk of the gas transfer will occur during this stage. The bullet has left the barrel and the barrel is now rapidly depressurizing. However, the pressure in the barrel is still greater than that in the gas cylinder; therefore, gas continues to flow from the barrel into the gas cylinder.

Stage 3: Pressure equalization has occurred in this stage. It marks the point of peak pressure in the gas cylinder. From this point forward, gas will be flowing from the gas cylinder back into the barrel. Gas is also flowing past the piston and exiting the gas cylinder as previously mentioned.

Stage 4: The gas cylinder is depressurizing. This stage normally lasts approximately three milliseconds.

Stage 5: The M1 Gas cycle is now complete. The gas cylinder has depressurized. The operating rod has reached its peak momentum. At this point the operating rod has moved rearward approximately 3/8 of an inch. The operating rod will coast rearward using the kinetic energy it gained to perform functions such as: unlocking the bolt, extracting the empty cartridge case, cocking the hammer, and compressing the operating rod spring.

...and one of these:

... if you plan to shoot modern, high power hunting ammo out of it.

GR