GW Staar

Member

- Joined

- Feb 26, 2009

- Messages

- 3,692

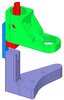

Test subject is the Lee 6000 which already has 6 stations, but that's the one I'm playing with because it's not dedicated to anything yet. Besides, for people who move their powder drop to #3, they have in effect only a 5 station press.

Not perfected yet......getting closer....need to close the bottom tighter.....third bullet got sideways and didn't fall. Using RCBS feeder and RCBS Gold Medal Seater......it's what I have right now.

Here's a little short video to show the idea behind it all. I know, not a critical project.....or everyone's cup of tea, but it's interesting to me...gives me something to do. Such a thing would be great for 5 station presses. Six stations on a five....

Guess I should mention that I was too lazy to put on the .223 shell plate......in the video is my 9mm shell plate for the last pistol loading session.....the cases wobble for that reason....but good enough for the first test.

Now if Lee would start making PISTOL bullet seaters with a drop-in window.....we could use their new inline pistol bullet feedrs with such a 2 in 1 coupler....

Not perfected yet......getting closer....need to close the bottom tighter.....third bullet got sideways and didn't fall. Using RCBS feeder and RCBS Gold Medal Seater......it's what I have right now.

Here's a little short video to show the idea behind it all. I know, not a critical project.....or everyone's cup of tea, but it's interesting to me...gives me something to do. Such a thing would be great for 5 station presses. Six stations on a five....

Guess I should mention that I was too lazy to put on the .223 shell plate......in the video is my 9mm shell plate for the last pistol loading session.....the cases wobble for that reason....but good enough for the first test.

Now if Lee would start making PISTOL bullet seaters with a drop-in window.....we could use their new inline pistol bullet feedrs with such a 2 in 1 coupler....

Last edited: