Are they truly the strongest? I have no idea currently. I like mine, and that's what is important but they are only 30-06.

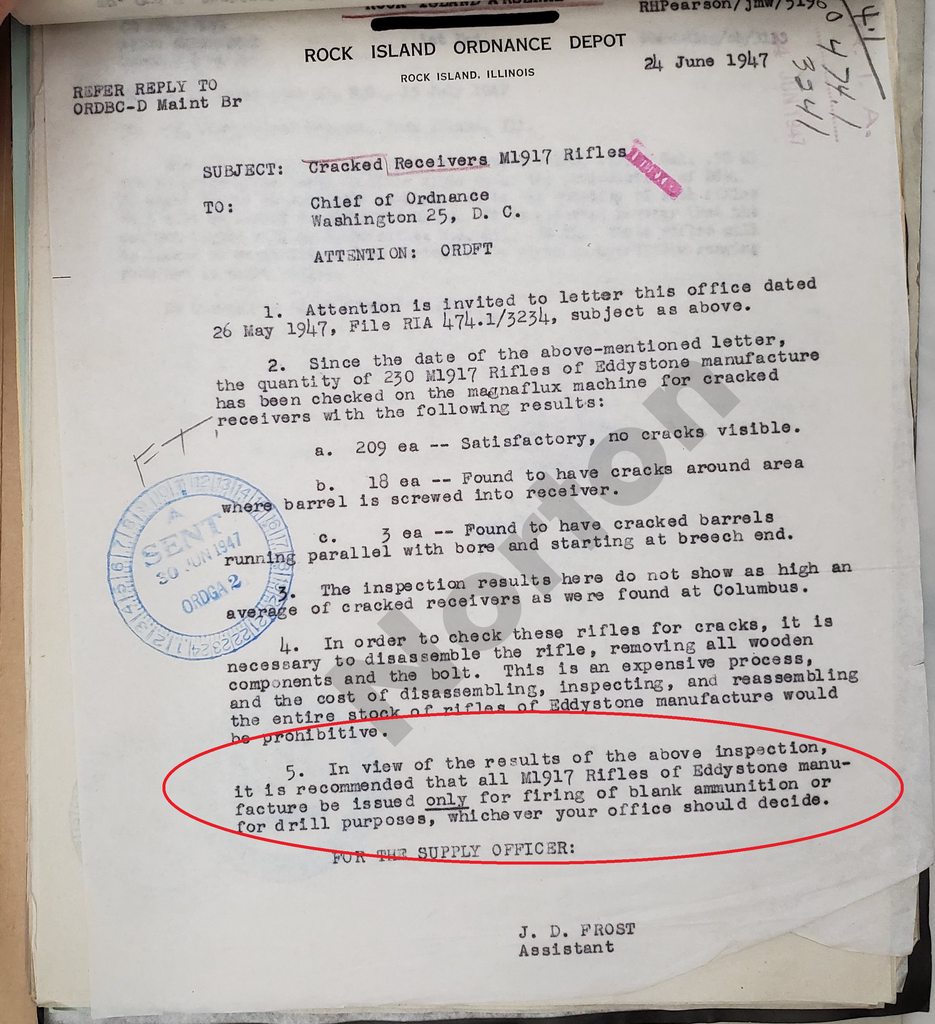

Prior to WW2, through the publication Man at Arms, and the American Rifleman, the Army Ordnance writers and the Regular Army Brigadier General who was the editor, promoted this Utopic view of all things Army. The Army was the best, its products were the best that ever was, and ever will be. And since the magazine was about shooting, both the M1903 and M1917 were of course, beyond perfection. Echos of this self serving, narcissistic grandiosity, are still rattling around in the shooting community.

The M1917 was a military action, and reflected some of the crazy military thinking of the time. Remember that the allies never issued parachutes to their pilots in WW1? Took the Germans a couple of years before their pilots had parachutes. Both sides considered pilots disposable, and if their planes went down, why should not the pilot? The German Military was running out of people faster, so they began to understand as disposable pilots were in normal situations, they were running out of them. Hence, parachutes. I am of the opinion this callousness towards human life, injuries, etc, is seen the M1903 and M1917 action. Shooter safety is not much of a consideration. If the action went bang, all was good. If the case head blew up, and the shooter lost his eye or face because the action vented gas directly in his face, well, there are always more Doughboys!

Gas handling in both the M1917 and M1903 is not even an after thought. Neither action protects the shooter against gas release. The M98 is just superb in this regard.

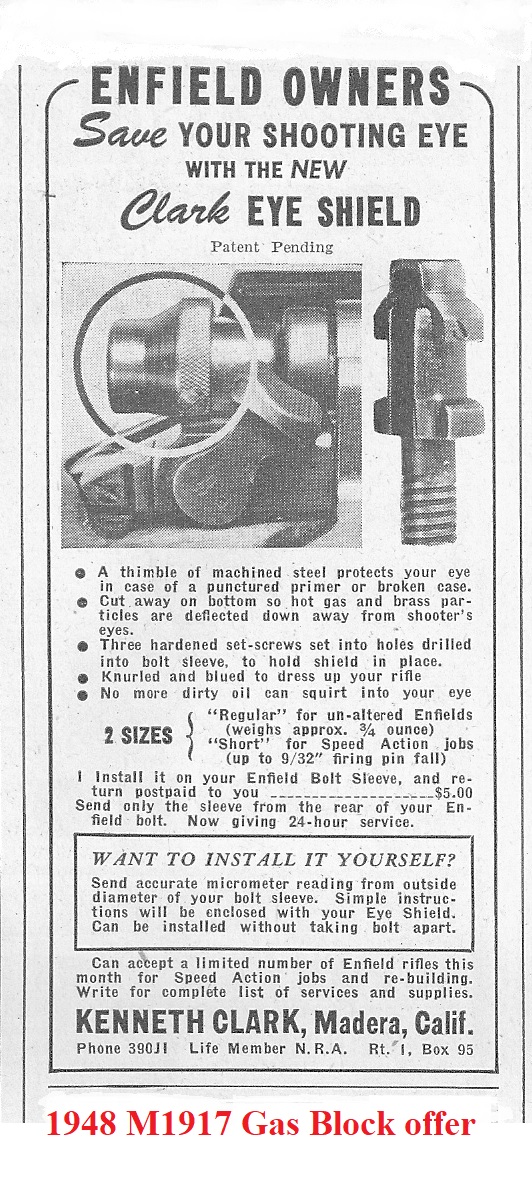

Pierce a primer and in both the M1903 and M1917, gas is going to flow straight down the firing pin into your eye. Gas will also travel down the left bolt race, under the bolt, directly into the shooters eyes and face. We know from ads, that this limitation was recognized in the M1917, and the after market was providing gas blocks for the firing pin.

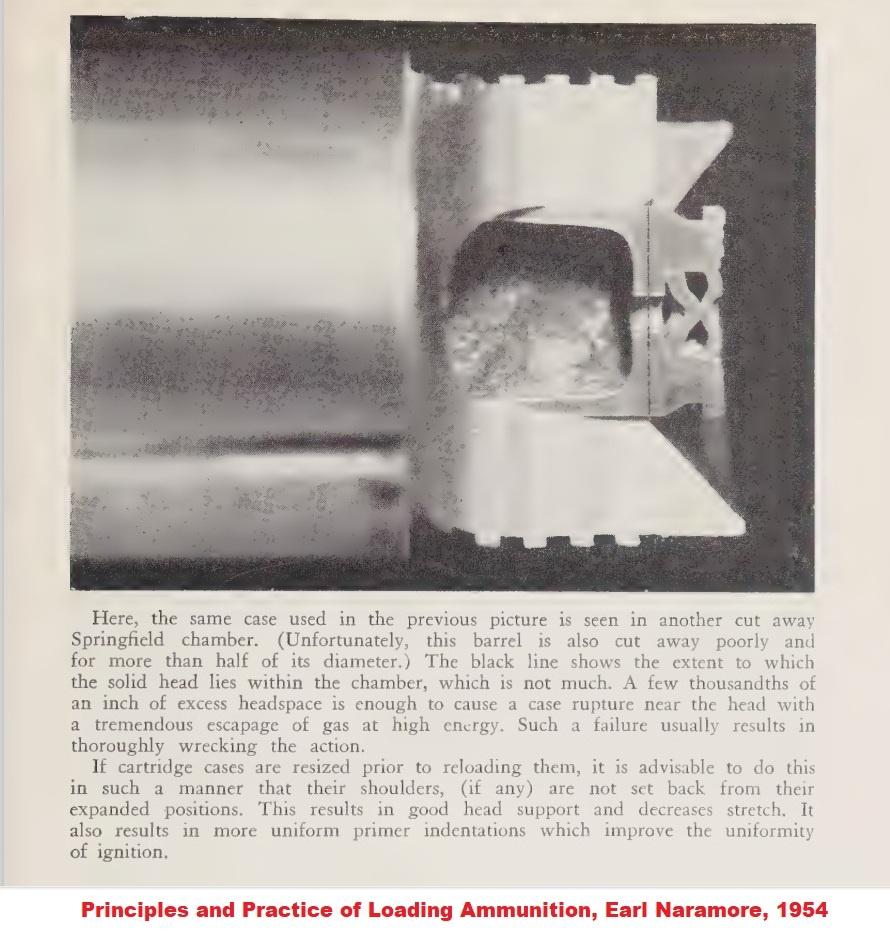

As so far as being "strong", both the M1903 and the M1917 are strong, till they are not. Neither supports the case head well, and that cone breech is going to vent gas inside that receiver ring, and it will be the lucky shooter whose receiver ring does not shatter in a case head rupture.

WW1 military actions all have their issues. As a class, they are not as safe as later actions. The Mauser M1898 had the best shooter safety features, but WW1 era M1898 fired cartridges of 43,300 psia, and the metallurgy of the era makes the use of higher pressure cartridges in those actions, risky. Period metallurgical technology produced crappy steel regardless of whether the steel was made in German, the US, or the UK. Old World technology in the Old World produced steels inferior in metal properties compared to the same composition today.

Go to this site if you want an extensive education on the material properties of

IRON, STEEL and SWORDS, . The author put a lot of work into the subject.

So the thing is, no one knows how strong, or how metallurgically good, their M1917 receiver is. I invite ideas about non destructive techniques. I think a test sequence similar to what is used for fire extinguishers. Fire extinguishers are expanded and contracted in a water tank. The amount of expansion has limits, and so does contraction. If the fire extinguisher expands too much, or bursts, it is bad. If if does not relax enough, it is bad. The shooting community thinks if the rifle survives one overload, that makes it good. Well, not in the long run. Naramore was warning about fatigue lifetime:

Principals and Practice of Loading Ammunition Earl Naramore

Page 86

Kinds of failures

There are two kinds of failures. Failure occurs when a single application of force exceeds the ultimate strength of the steel. This is the kind of failure that results from head separation or failures and is mistakenly believed by many shooter to be the only kind of failure that occurs; i.e, as long as a load does not develop enough pressure to burst the gun, it is safe. It is probably this mistaken belief that leads to the overloading of ammunition.

The second kind of failure is classed as a fatigue failure. Most mechanical parts fail as the result of the repeated applications of forces that are well below their yield strengths. The repeated stressing, however small, results in the accumulation of stress that concentrates around some stress raiser. When the total stress is high enough, the part breaks. These failures always occur suddenly and without warning. There is no initial expansion or visible cracking to give the least indication of any weakness.

All the conditions for fatigue failure are present in firearms. The forces applied in them are suddenly applied and the unit stress and unit deformation are double those of static or slowly applied loads of equal value. The forces are repeatedly applied, although not in the sense of the frequency that stress is imparted to an automobile connecting rod. What is more, the forces are of a magnitude that it is high in proportion to the yield strength of the steels used. ……………

Page 88

We have seen that, in the .30-06, with a chamber pressure of 48.000 psia, the effective total force on the bolt face could not exceed 8,000 pounds by very much. This is reduced by the stretch of the cartridge case. More of this would be lost in compressing the bolt lugs and their shoulder so, under these conditions, the amount of tensile stress reaching the outside of the receiver might not exceed two or three tons.

When the pressure drops, all of the stress does not leave the steel and the amount retained as stored energy is not the same at all points. The maximum rated pressure takes into account the accumulation of these stresses, the presence of the stress raisers normally present in the design and manufacture and the elastic limits of the steels used. As long as reloaders heed this limitation on pressure, they can expect a long and trouble free service from their firearms. However, when these pressure are grossly and persistently exceeded, the stored energy builds up much more rapidly for it increases, not directly as the increase in force, but as the square of it. The fact that a rifle may stand a few loads developing excessively high pressures does not signify that it will stand them if they are used persistently. If the tensile strengths of the steels were known, the areas of stressed surfaces could be measured and with known pressures, the probable life of a rifle could be figured. As I said before, there is nothing magic about this.

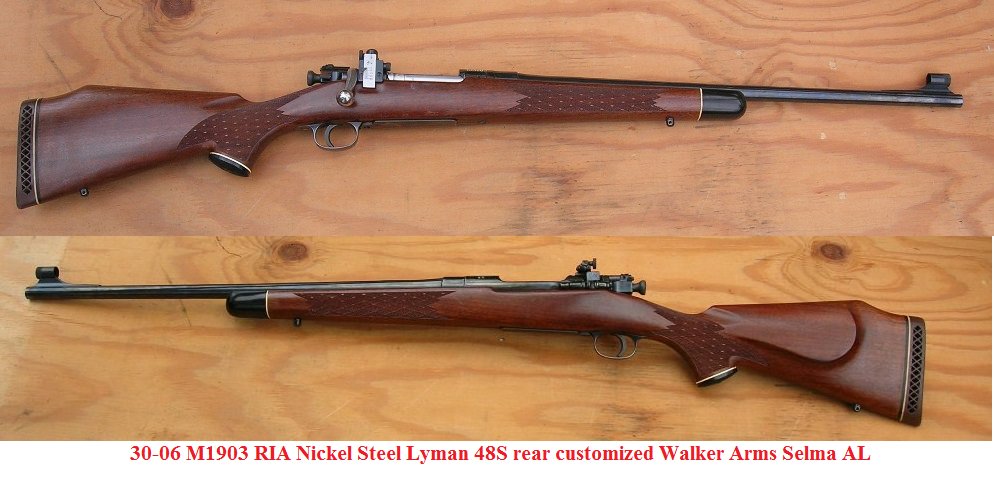

Post WW2, gunsmiths in print where shilling up a storm, all trying to sell their services. Foreign military rifles and actions were cheap, and the articles in print, fooled potential customers that they could create a rifle as good, or not better, than a M70 or M721, using a military action as the basis. Even at the time, even with relatively cheap gunsmithing labor, at the end of the process, a custom rifle like this

was going to be as expensive, if not more, than a brand new M70 or this rifle:

and I am going to say, that Remington M722 is absolutely superior in shooter protection features, and is made of better steels, under better process controls, than that WW1 era Rock Island receiver above.

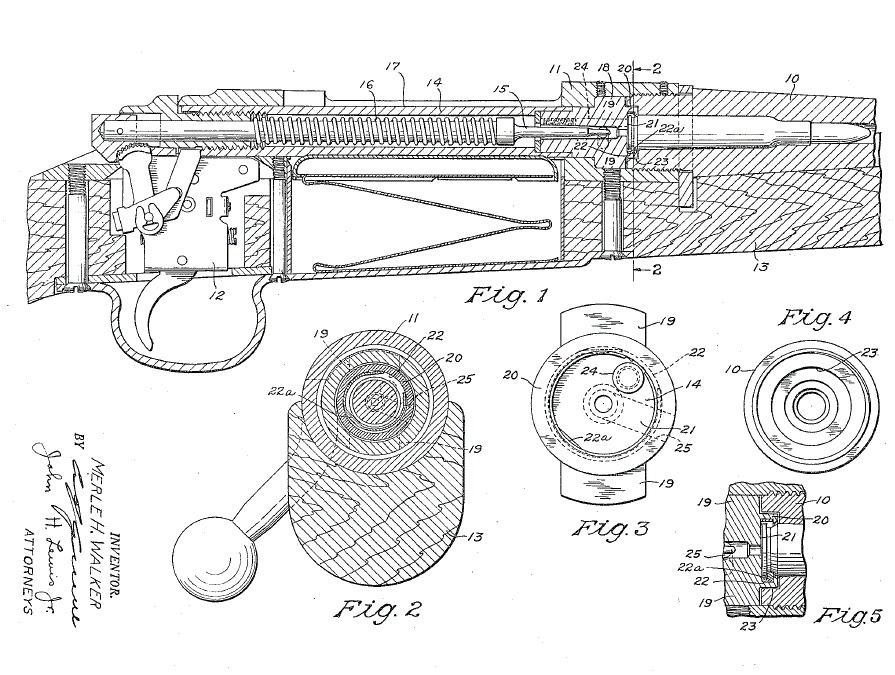

three rings of steel support the case head:

BREECH CLOSING CONSTRUCTION FOR FIREARMS 2,585,195

Merle H. Walker, lion, N. Y., assignor to Rem ington Arms Company, Inc., Bridgeport, Conn., a corporation of Delaware Application

Prior art firearms of the type employing fixed metallic ammunition have always been dependent upon the metallic cartridge case for securing obturation with the walls of the barrel chamber and preventing the rearward escape of gas from the barrel. As a result, the head of high intensity center-fire rifle cartridges has always been a massive chunk of brass of usually adequate strength to bridge over gaps between the end of the bolt and the chamber mouth, or clearance cuts for extractors, ejectors, and the like. However, in spite of this massive construction, the heads of cartridges, due to metallurgical deficiencies, barrel obstructions, or other difficulties, all too often fail in service, releasing white hot gas at pressures in excess of 50,000 pounds per square inch into the interior of the receiver. With some modern commercial and military rifles the effects of a burst head are disastrous, completely wrecking the action and seriously injuring or killing the shooter. One of the better known military rifles (M1903)

presents in alignment with the shooter's face a straight line passage down the left hand bolt lug guide groove, which, even though the receiver proper does not blow up, channels high pressure gas and fragments of the cartridge head into the location where they can do the most damage. It has been often, and truthfully, said that the Strength of most rifles is no greater than that of the head of the cartridges intended for use therein. The primary object of this invention is the provision of a firearm construction which is not thus dependent upon the strength of a cartridge head, ordinarily formed of a material of relatively low strength by comparison with the ferrous alloys used for the firearm structure.