mofosheee

Member

Hello The High Road

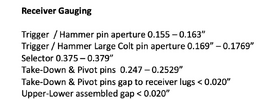

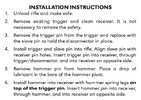

Recently purchased a new lower.........assembled with a new parts kit without issue to include a Geiselle trigger. Ran two mags and noticed that the the hammer pin had migrated out of the left side of the receiver, approx 0.125".

Reviewed the Midway and Brownells online tutorials to confirm proper assembly and searched the forum for a solution. I'm not understanding the errors in my assembly and prefer not to install an anti walk kit.

Please advise.

Thank again!

Recently purchased a new lower.........assembled with a new parts kit without issue to include a Geiselle trigger. Ran two mags and noticed that the the hammer pin had migrated out of the left side of the receiver, approx 0.125".

Reviewed the Midway and Brownells online tutorials to confirm proper assembly and searched the forum for a solution. I'm not understanding the errors in my assembly and prefer not to install an anti walk kit.

Please advise.

Thank again!