IWAC

Member

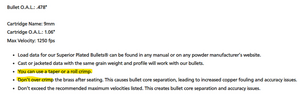

I have a lot of Berry's 125 gr. plated, supposedly .357 bullets. Measuring random projectiles, I get mostly .3565 diameter. Now, I realize my Caliper isn't one of the super accurate brands, and think that the difference may be related to the caliper's manufacturing tolerances. I also think that with a stiff .38 Special +P load...max, about 900 fps., the bullet should obturate enough to fill the chamber/grooves of my revolver. The bullets also have no crimping groove or cannelure, and Berry's website says DON'T crimp!  It will damage the plating! They recommend a taper crimp, just enough to move the case mouth back against the bullet, totally eliminating the flare. They say a taper crimp has enough neck tension to hold the bullet. My question is: My dies do both taper and roll crimping. What would happen if I seat the bullet deep enough that a teeny roll crimp over the curve where the body of the bullet tapers down to the nose, giving a bit more security from bullet "creep"? It seems to me the alternative would be to remove a smidgen from the expander plug diameter, providing a bit more neck tension. Am I on the right track? Suggestions, please!

It will damage the plating! They recommend a taper crimp, just enough to move the case mouth back against the bullet, totally eliminating the flare. They say a taper crimp has enough neck tension to hold the bullet. My question is: My dies do both taper and roll crimping. What would happen if I seat the bullet deep enough that a teeny roll crimp over the curve where the body of the bullet tapers down to the nose, giving a bit more security from bullet "creep"? It seems to me the alternative would be to remove a smidgen from the expander plug diameter, providing a bit more neck tension. Am I on the right track? Suggestions, please!

It will damage the plating! They recommend a taper crimp, just enough to move the case mouth back against the bullet, totally eliminating the flare. They say a taper crimp has enough neck tension to hold the bullet. My question is: My dies do both taper and roll crimping. What would happen if I seat the bullet deep enough that a teeny roll crimp over the curve where the body of the bullet tapers down to the nose, giving a bit more security from bullet "creep"? It seems to me the alternative would be to remove a smidgen from the expander plug diameter, providing a bit more neck tension. Am I on the right track? Suggestions, please!

It will damage the plating! They recommend a taper crimp, just enough to move the case mouth back against the bullet, totally eliminating the flare. They say a taper crimp has enough neck tension to hold the bullet. My question is: My dies do both taper and roll crimping. What would happen if I seat the bullet deep enough that a teeny roll crimp over the curve where the body of the bullet tapers down to the nose, giving a bit more security from bullet "creep"? It seems to me the alternative would be to remove a smidgen from the expander plug diameter, providing a bit more neck tension. Am I on the right track? Suggestions, please!