All,

I have just started casting my own bullets. After a bit of practice, I was finally able to turn out near 100% keepers of 124gr Lee TC out of a 6 cavity mold. The mold was turning out slightly oversize and out-of-round bullets, so I sized them to .3563 and tumble lubed them with Lee Liquid Alox. Let the bullets 'dry' for two days before loading- they were no longer tacky.

I shot them in a Ruger SR9, that was broken in with about 700 rounds of quality FMJ bullets. I followed this with a thorough cleaning of the barrel. No problems with these cartridges functioning in the Ruger- it eats everything I feed it. BUT- I believe I'm getting more leading that I should.

The alloy is very close to Lyman #2, with a BHN of around 15 or 16. I loaded the rounds with 4.2gr of Winchester WSF, and the chronograph showed I was getting average speed of 989fps, ES of 30, and Std. Dev of 10 (wow... that surprised me). That was over a 10 shot string, after breaking in the barrel with 15 rounds first. I was concerned that I had to put my COL at 1.065, due to the last micro groove on the Lee bullet being quite near the shoulder of the bullet. I usually run XTPs at 1.085, but I've never had to put a bullet this deep in the case (this bullet is the same OAL as a Hornady 115 FMJ.)

Here's a typical as-cast bullet- no resizing yet:

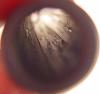

Now for the ugly- here's the pics. This is the barrel after shooting 200 rounds of these bullets over an afternoon of shooting:

Any thoughts how to improve the leading situation? I may move up to .357 or so on the sizing- but have not yet slugged the barrel (don't have a way to do that yet).

Is this considered bad, medium, low, or normal lead fouling for 9mm?

Thanks!

I have just started casting my own bullets. After a bit of practice, I was finally able to turn out near 100% keepers of 124gr Lee TC out of a 6 cavity mold. The mold was turning out slightly oversize and out-of-round bullets, so I sized them to .3563 and tumble lubed them with Lee Liquid Alox. Let the bullets 'dry' for two days before loading- they were no longer tacky.

I shot them in a Ruger SR9, that was broken in with about 700 rounds of quality FMJ bullets. I followed this with a thorough cleaning of the barrel. No problems with these cartridges functioning in the Ruger- it eats everything I feed it. BUT- I believe I'm getting more leading that I should.

The alloy is very close to Lyman #2, with a BHN of around 15 or 16. I loaded the rounds with 4.2gr of Winchester WSF, and the chronograph showed I was getting average speed of 989fps, ES of 30, and Std. Dev of 10 (wow... that surprised me). That was over a 10 shot string, after breaking in the barrel with 15 rounds first. I was concerned that I had to put my COL at 1.065, due to the last micro groove on the Lee bullet being quite near the shoulder of the bullet. I usually run XTPs at 1.085, but I've never had to put a bullet this deep in the case (this bullet is the same OAL as a Hornady 115 FMJ.)

Here's a typical as-cast bullet- no resizing yet:

Now for the ugly- here's the pics. This is the barrel after shooting 200 rounds of these bullets over an afternoon of shooting:

Any thoughts how to improve the leading situation? I may move up to .357 or so on the sizing- but have not yet slugged the barrel (don't have a way to do that yet).

Is this considered bad, medium, low, or normal lead fouling for 9mm?

Thanks!

Last edited:

all out... or you can cough up the price of one box of pistol ammo for a Lewis Lead Remover from Brownell's.

all out... or you can cough up the price of one box of pistol ammo for a Lewis Lead Remover from Brownell's. all the lead out - mechanically - so you can clean your bore from there. No point in just polishing up the lead that's staying in your barrel. This tool is one item I wish I'd had decades before. I guarantee you'll like it.

all the lead out - mechanically - so you can clean your bore from there. No point in just polishing up the lead that's staying in your barrel. This tool is one item I wish I'd had decades before. I guarantee you'll like it.