Hey I'm getting lead shaving while seating my 125 grain 9mm LRN's. I've tried backing the crimp off up to the point where they no longer drop into the chamber, and also belled the cases an insane amount, but still shaving. Any suggestions? It's only a slight around the case mouth. Or is that normal?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

lead shaving

- Thread starter jrkfantom

- Start date

- Status

-

Not open for further replies.

beatledog7

Member

What's the bullet diameter? Did you chamfer the case mouths? Sometimes the sharp edge can cause shaving if you don't get the bullet started in perfectly straight.

john16443

Member

If your using a single die that seats and crimps, it may not be set up correctly. If you have enough flare on the case to accept the base of the bullet, you shouldn't get any shaving unless you're inadvertently removing the flare (or overcrimping) before the bullet is set at its final depth. I separate the seating and crimping in separate dies, no shaving with minimal flare.

LiveLife

Member

No, it's not normal. For .356" diameter lead bullet, adding .020" (average combined thickness of case walls) will give you .376", at which the flared case neck should return flat back against the side of the bullet.jrkfantom said:I've tried backing the crimp off up to the point where they no longer drop into the chamber, and also belled the cases an insane amount, but still shaving ... It's only a slight around the case mouth. Or is that normal?

I seat and taper crimp in the same step and sometimes get some lube pushed up on top of the case neck. I may get a sliver of lead if a case has particularly thick walls.

When I setup the bullet seat/taper crimp die, I use an empty resized/flared case (no primer) to set my taper crimp. For .356" diameter lead bullet, I would adjust the die body until the taper crimp measure .376". I would resize/flare the case again and seat the bullet to the determined Ideal OAL.

I use .376" taper crimp for .356" Missouri Bullet 9mm 125 gr RN, CN and SWC bullets and most of the times, do not get shaving of the lead.

beatledog7

Member

A related thought: what's the diameter of your flaring button/insert? It needs to be a thousandth or two bigger than the bullet you're using.

LiveLife

Member

I believe neck tension comes from the force/friction applied to the bullet by the wall of the resized case.

Flat taper crimp does not indent the surface of the bullet and allows the case neck rim to "head space" on the chamber. For this reason, even though you seat/taper crimp lead bullet in the same step, you should not shave the side of the bullet unless the case wall is thicker than typical.

Slight taper crimp (.001"-.002" less than the combined measurement of the bullet diameter/thickness of the case walls) slightly indents the surface of the bullet to allow better feeding/chambering of the finished round but does not increase the neck tension. If you apply too much taper crimp when seating/taper crimping lead bullet in the same step, you'll shave the side of the bullet. For this reason, some reloaders prefer to seat and taper crimp lead bullets in separate steps when using more than flat taper crimp.

Roll crimp applied into the crimp groove does not increase the neck tension, but "holds" the bullet from moving forward during heavy recoil (like .357/.44 magnum recoil) and provides increased resistance when powder ignites to help build more consistent chamber pressures. For this reason, many reloaders do not use roll crimp but taper crimp for lighter recoiling .38 Spl loads.

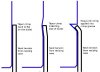

Below is a not-to-scale drawing to show comparison between flat taper, slight taper and heavy roll crimp.

Flat taper crimp does not indent the surface of the bullet and allows the case neck rim to "head space" on the chamber. For this reason, even though you seat/taper crimp lead bullet in the same step, you should not shave the side of the bullet unless the case wall is thicker than typical.

Slight taper crimp (.001"-.002" less than the combined measurement of the bullet diameter/thickness of the case walls) slightly indents the surface of the bullet to allow better feeding/chambering of the finished round but does not increase the neck tension. If you apply too much taper crimp when seating/taper crimping lead bullet in the same step, you'll shave the side of the bullet. For this reason, some reloaders prefer to seat and taper crimp lead bullets in separate steps when using more than flat taper crimp.

Roll crimp applied into the crimp groove does not increase the neck tension, but "holds" the bullet from moving forward during heavy recoil (like .357/.44 magnum recoil) and provides increased resistance when powder ignites to help build more consistent chamber pressures. For this reason, many reloaders do not use roll crimp but taper crimp for lighter recoiling .38 Spl loads.

Below is a not-to-scale drawing to show comparison between flat taper, slight taper and heavy roll crimp.

Attachments

Last edited:

Sounds like what may be happening. I almost had the same problem seating some .4545 lead bullets in .45 Colt cases using an RCBS die not long ago. The seater was removing some of the bell as the case was going up in the die. I had to get the bullets seated really straight before running them in the die.You can bell the crap out of the case mouth, but the seater die will unbell it when you seat the bullet. If the bullet diameter plus case wall thickness exceeds the die's internal diameter, the bullet will get shaved.

beatledog7

Member

No. It needs to be .001" or so smaller than the bullet he is using.

You're right. I misspoke

Fatelvis

Member

I seat and crimp in seperate steps (progressive machine), and think it is a much better way to go. You will never shave lead do it that way. I do see the appeal to a seat/crimp die, especially when not using a progressive setup though. Remember if you "overbell" your brass, you will get neck splits much faster.

The problem here is, I believe, a sizer squeezing the bell back in, plus fat bullets, which is causing some shaving upon seating. That would happen whether they crimped in a separate step or not. It isn't the crimp doing it, unless it is adjusted for too much crimp.

When properly taper crimped, there is so little bullet movement going on while the "crimp" is applied you will not get shaving, or at least I never did with auto calibers using a light taper crimp.

When properly taper crimped, there is so little bullet movement going on while the "crimp" is applied you will not get shaving, or at least I never did with auto calibers using a light taper crimp.

Fatelvis

Member

With all due respect Walk, The belling is after the sizing. I don't understand how the sizer could effect the belling.?? I've had plenty of shaved lead in my days of using the combo seat/crimp die. Doesnt matter if your using a roll or taper crimp, the fact remains that you're trying to push the bullet in, as you're crimping/ pinching the case mouth into it.The problem here is, I believe, a sizer squeezing the bell back in

Blue68f100

Member

Hey I'm getting lead shaving while seating my 125 grain 9mm LRN's. I've tried backing the crimp off up to the point where they no longer drop into the chamber, and also belled the cases an insane amount, but still shaving. Any suggestions? It's only a slight around the case mouth. Or is that normal?

When reloading lead bullets with flat bottoms, the cases need to be flared so the bullet can start without shaving. You only want to use the bare minimum required flaring to make the brass last long as possible. Then you set your crimp (TC) to remove the flare so the round will chamber easily. Most jacketed including plated bullets have a small radius on the bottom to make seating easier without having to open the mouth up more. It also helps to camphor the inside of the case. But being a pistol ammo this is a little impractical due to the volume.

Over bell a scrap case, measure its width, then run it in the sizer stopping short of the crimp. Measure it again. Some combinations can squeeze the bell down enough to shave lead on fat lead bullets. RCBS makes their "Cowboy" dies with a little extra room in them just for over sized lead bullets sized to fit throats. Most times this will not happen, but the OP said he is belling an "insane amount", so we know the belling is enough. That means the sizer is pushing the bell back in, or he is crimping too much, causing lead shaving. IMHO of course.I don't understand how the sizer could effect the belling.??

- Status

-

Not open for further replies.

Similar threads

- Replies

- 16

- Views

- 3K

- Replies

- 9

- Views

- 1K

- Replies

- 3

- Views

- 659