He's not the only one. Pretty impressed that transit time from Norway was only four days.Good to know someone is reading my post!

I know what could be wrong for $24+$9 shipping.

Slightly concerned about the small print: additional taxes and custom fees may apply

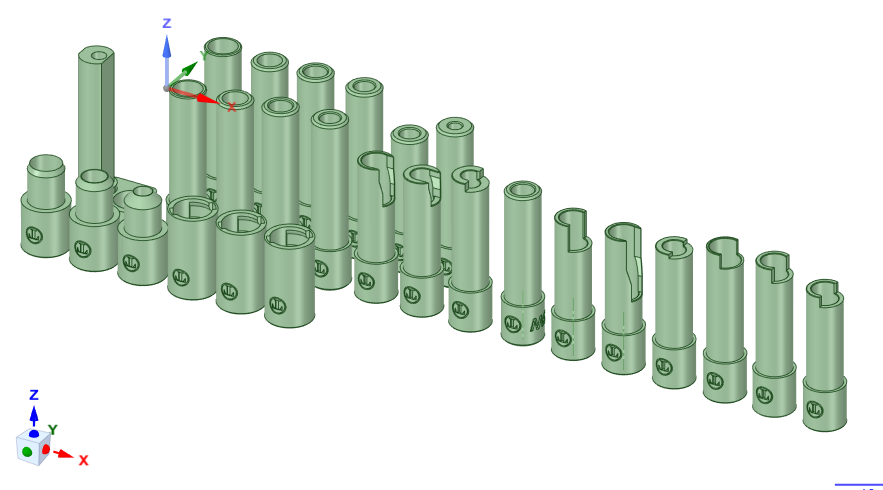

I was torn between the printed part or getting the file to print my own...then there's the choice of color. Figured there's be fewer issues with the correct spring in place and the metal pivot pin....so I ordered the one with all the hardware included