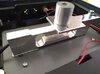

UPDATE: Fine tuning load cell mount plate

NOTE: DO NOT use magnetic screw driver or sources of magnetic field around the scale.

TIP: Level the scale with adjustable feet until slight force down on each corner won't affect display reading.

I turned on the scale (On battery power) and quickly found out magnetic screw driver around the load cell was affecting the display reading.

Out of curiosity, using non-magnetic screw driver, I applied slight force down near each of 4 mount screw and found 2 of them affected readings by .003 - .005 gram. So I loosened all the screws and display did not show change when I applied slight force down near each mount screw. Then I incrementally lightly tightened each mount screw while checking slight down force. (Too much tightening and display changed from "0.000 g")

I got to the point where I lightly tightened the 4 mount screws where pushing down near each mount screw did not change the display of "0.000 g".

With my zero now not affected by twist/flex of the steel mount plate, I calibrated the scale (Still with the cover off but all the windows/doors closed as air movement affected display reading) with the 100 gram calibration weight and started verifying Ohaus ASTM Class 6 check weights. (

TIP: Level the scale with adjustable feet until slight force down on each corner won't affect display reading)

Guess what?

Absolutely no drift of zero and no need for "tare".

Scale still with cover off verified check weights down to 0.005 gram (5 mg/.08 gr).

I put the cover back on and noticed too much tightening of any screw could affect display reading so go easy on the screws.

Thanks to jmorris who made me open up the scale to check the load cell, I learned a valuable takeaway - When load cell mount plate is not mounted/tensioned properly and used out-of-level, it could affect consistency of readings.

Next test is making a side panel with a hole for tip of powder trickler.