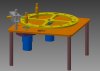

With the 308win new brass supply all dried up, figured it was time to start annealing. I rigged up a home made annealer to get consistency in results...and this is what I got.

Annealing time of 6 seconds for all brass yielded the results in the picture attached. Settled on 6 seconds because at 6.5 seconds, the FC brass started to get faint dull red.

Most of the brass is FC, but the 2 far right in the picture are Hornady. They weighed noticeably less than the FC. When observing in a darkened room, the case mouth definitely glowed dull red with the Hornady. A very brief release of orange flame also noticed right before it left the flame.

No glow and no orange flame for the FC brass. All brass were air cooled.

So my question is with regards to the Hornady brass. Are they ruined? Is it still safe to use?

Thanks!

Annealing time of 6 seconds for all brass yielded the results in the picture attached. Settled on 6 seconds because at 6.5 seconds, the FC brass started to get faint dull red.

Most of the brass is FC, but the 2 far right in the picture are Hornady. They weighed noticeably less than the FC. When observing in a darkened room, the case mouth definitely glowed dull red with the Hornady. A very brief release of orange flame also noticed right before it left the flame.

No glow and no orange flame for the FC brass. All brass were air cooled.

So my question is with regards to the Hornady brass. Are they ruined? Is it still safe to use?

Thanks!