I have been powder testing for my 6.5/284 and have narrowed my powder and charge weight down.

The next step i took was using the hornady OAL gauge to find my seating depth.

I am a bit inexperienced in using it. My reading which i took 6 times was 3.140 with a 140 grain 6.5 sierra matchking

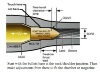

I am a bit concerned because at that depth very little of the bullet is in the case mouth. Actually just barely past the boat tail contour makes it into the case mouth.

I do know i would back of the lands a touch but this seems to far to seat this particular projectile.

Anyone reloading for 6.5 have some advice on it?

Thanks

The next step i took was using the hornady OAL gauge to find my seating depth.

I am a bit inexperienced in using it. My reading which i took 6 times was 3.140 with a 140 grain 6.5 sierra matchking

I am a bit concerned because at that depth very little of the bullet is in the case mouth. Actually just barely past the boat tail contour makes it into the case mouth.

I do know i would back of the lands a touch but this seems to far to seat this particular projectile.

Anyone reloading for 6.5 have some advice on it?

Thanks