Awesome feedback, BCrider!

"Or the other option is to simply let the casing head form back onto the rounded face. I seriously don't think it'll rupture."

Seeing how poorly supported the chamber is in my blowback semi (Baikal MP161K) shooting hot ammo, where the rim blows out into a near constant 45deg taper, I think the 22LR case can handle a little deformation without kaboom. In a higher power or centerfire gun, I think the problem would be more due to the relative rigidity of the cases and how they are glued to the chamber under pressure, which would put great stress on them where the case wall starts (truly poor headspace condition). The 22LR case is so thin and low pressure, the metal can more freely shift around without tearing --that's my theory, anyway.

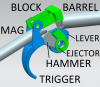

"Your animation has a few flaws though. The ejector is shown returning into position AFTER the new round is chambered. I'm thinking that it needs some way of returning or being pushed to return by the fresh round."

This is totally me being a lazy animator. It is incredibly tedious to make an animated GIF frame by frame; you have to create copies of every part at every position, then hide all the other copies not needed for each screenshot. The ejector is driven mechanically forward by a pin in the lever (only on the return stroke), but is on a slotted pivot hole so it can slide up and down enough to slip over the case rim when the block drops down behind the fully-chambered case(onto the tip of the extractor). In reality, this would occur in the last little bit of lever motion, which I did not bother to animate (which is why the lever appears to reach forward before the extractor slips over

). I may re-animate the last couple slides to reflect the reality, if I feel like it.

"The other thing I'm seeing is that the magazine catch is driven by the lever. But there's nothing to catch the round behind the one being chambered when the lever is cycled forward. With only the one rim catch in the magazine it would be free to double feed or even shoot out the whole lot. It needs a second lip or some other method to control and limit the feed to one round only."

The magazine catch actually does a little two-part motion (the spring seat shown is for a weak wire spring that coils around the mag tube). The first part, it pivots near the spring seat, and the

escapement catch at the rear/tail moves inward to catch the rim of the next shell (I modeled it wrong, though; it needs to be positioned just

after the next rim, not before. In the current shape, the new round would only feed .02" and then stop

), and once the

escapement catch has contacted the shell the tip of the forward catch will lift out of the way of the front case's rim; allowing the stack to move a little less than a full cartridge length. Once the catch lever is released on the return stroke, the stack will advance the rest of the way.

"Or is this intended to catch the new round on the ejector? And at that point the lever begins to come back which lets the rim catch in the magazine hold back the next round while at the same time the nose of that captured round keeps the chambering round pressed against the ejector?"

I thought briefly about this, but not much. I want to ensure the catch holds the rounds

outside the gun, so it can be stowed while loaded ('bout time someone made a front-loading tube mag --talk about fast reloads!). But let's see; if the extractor was a 'notch' instead of a blade, which engaged the rim, it would both push and pull the cartridge. You'd need some hammer relief to support the material added (so the ejector isn't supporting the case itself), but that's not a very big deal. So the new round would squirt out of the mag, come to rest against the ejector, then be dragged forward the rest of the way on the return stroke. That does sound like a pretty slick little system, depending on how 'slippery' those 22LR rims, are. I was more worried that the gyrations of the round slipping into the bore would cause it to 'fishtail' away from anything that could grab the rim, so I opted for a simple push system; but since I've had to add the sliding-axis element (it slides both ways, so the extractor has more "reach" when it comes to feeding the new round in), the true controlled feed extractor you've described might be possible, too.

"The first step would/should be to make up a barrel in a block receiver that copies your hinged breech block and test fire some rounds to see if the rounded face on the lower edge results in a lockup at all."

The block is rounded, so if the arc is correct there should be no reason it couldn't slide along the deformed case head. I had intended to do the test you described, if only because the true single-shot portion of the design would be completed way before the likely-to-be-obnoxious-if-not-non-functional repeating action. I'm an impatient man

"Ya know.... if the hinge pin for the rotating block and trigger could be located at or even a hair below the lower edge of the chamber the hinged block's face could be straight up and down and flat. And when it lifts it would be hinged in such a way that it would lift back a little off the case head as it rises. Much like the falling "L" block in a Stevens Favourite hinges down and back by having the hinge point located below the barrel."

Yes, at this point I could move the breech/trigger pivot down without as much impact on function as I'd expected it to cause, initially (it's hard to visualize how much 'flex' a design can accommodate until it is completed). In fact, dropping the lever/pivot about a 1/4" and raising the bolt pivot the same would allow the block to drop

down like a proper falling block, without hitting anything.

The reason I'd rather not drop the rear pivot is because I'd have to drop the bolt forks. The mag tube is the same width as the forks, so they would interfere unless I cut the mag tube back quite a bit or cut reliefs in its sides. Raising the rear pivot and dropping the lever would have the beneficial opposite effect, but would make the action larger --I'm not sure it'd be worth growing the action above the top of the barrel, but it'd be kind of funny to use the bolt forks as the rear sight

. One super-cool side effect would be that the hammer would hold the bolt in line with the barrel like a rolling block, on such a setup. If the pivot is below, there will be significant upward force on the block during firing that will have to be contained, somehow.

"I'm also wondering what raises the block? Or is chambering a fresh round a two step process that starts with pivoting the block back and up and then cycling the trigger guard/lever? If so then what locks the hinged block in place? Or are you relying on the fact that the block is inline with the pressure? "

It's not modeled yet, but I have two pretty simple solutions. The most simple is to have one of the forks hang down lower, and come into cammed contact with the lever, rising fully to eject at the 1/2 stroke point (if I wanted to be fancy, the fork would hang down low enough to form a cam slot for a pin on alongside the lever, but it will only be a ramped surface on this design). The other solution is for a spring between the lever and block to be tensioned when the lever is rotated; like a pushrod, but with 'give' so they don't truly need to move in unison. In both cases, the block is dropped back down by a simple return spring (the trigger return spring) once everything is back in battery and out of the way. I suppose the 'forward assist' for sticky rounds would be slapping the top of the action to get the block down

. Being in line with the bore (or more likely, .01" or so above it) there should be no load acting in the upward direction on the block under pressure.

1) Trigger pulled, hammer drops

2) Lever pulled, drives up block, begins cocking hammer spring against ejector

3) ~1/2-3/4 lever draw, block rises fully, allowing ejector to freely eject spent case (can't make ejection/feeding too close or the cases will collide when levered rapidly)

4) Lever continues fully, actuating the shell release to advance one cartridge, and catching the hammer on the trigger sear

5) Lever reverses, driving the ejector forward against the case rim and hammer spring

6) Lever continues until the ejector fully chambers the case, allowing the block to fall onto the ejector blade

7) Blade is driven downward, and slips over the case head as the lever comes to rest

At this point, the ejector is tensioned, and pulling the case rim to the rear with the force of the hammer spring (which means the lever will not stay closed with an empty chamber until the hammer is discharged). It has no momentum, so I am not worried about ignition, but I do wonder if this effect could damage the case rim. At any rate, the gun would not be left cocked for very long.

I suppose I could add a feature to the block to 'hold' the ejector in place when no cartridge is present, which would allow for proper dry fire, but that's a fairly low priority (esp. when holding the lever back will still tension the hammer spring). If marketing, I'd call it a 'dry fire preventer' and claim it prevents damage (even though the ejector is the 'anvil' for the hammer, and will be both replaceable and very hard

)

"If I sussed this out right then I think you're onto a bit of brilliance here. If you can make this work you'll really have something. And a design which I suspect could be sold to some outfit to turn it into at least a small series production."

That'd be fun and all, but there're a few reasons I'm posting this online, as opposed to pretending like I have some great secret that needs guarding. 0) It's likely not half as good an idea as I think it is

, 1) It's probably already patented somewhere, same as every other gun-action idea, 2) I'd get all the satisfaction I desire from building even a single one of these, and 3) sales/marketing is not my day job for an even greater number of reasons

TCB