Akula69

Member

Not sure whether this has been addressed before, but here goes:

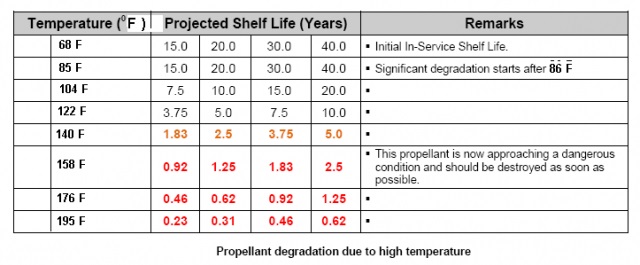

I am wondering whether the powder that I (we?) have on hand would be better preserved inside the original, unopened containers or safer sealed in a loaded round. Both would be stored properly in a climate-controlled environment...the loaded rounds are further protected in 1K round sealed bags with desiccant packs.

Specifics: I have 4 lbs. of AA#5 that I plan on using for .38 special. I have the projectiles and cases ready to go for loading...but I've had the powder now (in the original containers) for 4 years and don't want to lose it. The powder is stored in a powder cabinet at ~50% humidity and 67 degrees (as are all the loaded rounds). I probably go thru about 2K .38 rounds per year in instructor requalification and practice.

What do the masses say?

I am wondering whether the powder that I (we?) have on hand would be better preserved inside the original, unopened containers or safer sealed in a loaded round. Both would be stored properly in a climate-controlled environment...the loaded rounds are further protected in 1K round sealed bags with desiccant packs.

Specifics: I have 4 lbs. of AA#5 that I plan on using for .38 special. I have the projectiles and cases ready to go for loading...but I've had the powder now (in the original containers) for 4 years and don't want to lose it. The powder is stored in a powder cabinet at ~50% humidity and 67 degrees (as are all the loaded rounds). I probably go thru about 2K .38 rounds per year in instructor requalification and practice.

What do the masses say?