Got my new Dillon SDB in .45ACP setup today. I was able to get the powder thrower to throw the right amount and got the bullet seater set to the correct length. I have a problem and several questions. I will number them to make the replies easier.

1. What is the best primer to use with the Dillon primer system? I was using CCI Large Pistol today and was having problems getting the pickup tube to pick them up. One try I could get about 30 in and no more would go no matter how hard I pushed. Another time I could only get about ten. It seems they were getting hung up in the green tip. They slid up and down in the tube fine. I know I'm using the right adapter and tube. Any advice? I also have the Dillon Flip tray. Hope someone can tell me what I'm doing wrong.

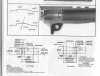

2. I loaded about 10 test rounds on the press today. Over half of the wouldn't go all the way into the case checker. There would be a little bit sticking out of the top. Not much, but they wouldn't just fall into the case checker like factory ammo or some of the others I loaded. Most of this brass was fired in a Glock 21, the rest in a 1911 or HK USP. Is this a case of the Glock buldge or is this something wrong with my crimp. My OAL on all of the rounds were 1.250 or 1.251. I know length isn't an issue? A'm I going to need to get a FCD or an Undersize die for EGW for my single stage?

1. What is the best primer to use with the Dillon primer system? I was using CCI Large Pistol today and was having problems getting the pickup tube to pick them up. One try I could get about 30 in and no more would go no matter how hard I pushed. Another time I could only get about ten. It seems they were getting hung up in the green tip. They slid up and down in the tube fine. I know I'm using the right adapter and tube. Any advice? I also have the Dillon Flip tray. Hope someone can tell me what I'm doing wrong.

2. I loaded about 10 test rounds on the press today. Over half of the wouldn't go all the way into the case checker. There would be a little bit sticking out of the top. Not much, but they wouldn't just fall into the case checker like factory ammo or some of the others I loaded. Most of this brass was fired in a Glock 21, the rest in a 1911 or HK USP. Is this a case of the Glock buldge or is this something wrong with my crimp. My OAL on all of the rounds were 1.250 or 1.251. I know length isn't an issue? A'm I going to need to get a FCD or an Undersize die for EGW for my single stage?

Last edited: