rdnktrkr said:A good addition is a power strip and a good light, I use big desk lights and the big circle ones with a magnifying glass.

The Husky I've ordered has ...

- Built-in power strip w/ 6 outlets and 2 USB for easy charging

rdnktrkr said:A good addition is a power strip and a good light, I use big desk lights and the big circle ones with a magnifying glass.

......The problem with mounting presses to the front of a 32" deep bench is that you lose access to so much usable space. With a 2' deep bench, you're not giving up so much. When I pick up the Husky workbench tomorrow I'll be able to see if the bench will tuck away under the 8'x2' bench. If so, I'll be able to roll it out and use the worktop for gun cleaning, case trimming, working on stocks, barreled actions etc., and then roll it back under when done.

dredd said:You will be happy with that box.

I picked one up last year on sale because it was super cheap.

I have several big Kennedy's that I have accumulated over the years.

"Cheap" boxes have come a long way since the 70's & 80's.

I was hoping to situate the rolling bench under an 8'x2' table, but with the added height of the casters it's not going to happen.

jmorris said:What if you put casters on the 8x2 table? Then you could nest and move both easily.

So far I'm really pleased with how this is going. I've got the 6' bench set up and dedicated to the single stage press which I moved from the center to the end of the bench. I have room for powder dispensing and annealing and there's enough room on the bench for other "projects" or activities such as case trimming, priming etc. For now I'm going to focus on getting the three progressive presses set up on the other bench to the left. I might even be able to have case trimming and priming set up "permanently" on that bench too. I need to clean up and organize the shelves above the toolbox but that'll have to wait. I should have bought a tool box for this room a long time ago. I haven't figured out what I'm going to put in the drawers yet but I can roll the bench into the center of the room and use if for cleaning firearms or anything else that requires some space.

In case anyone's wondering, the bench in the corner is 6'x30", the tool box top is 52"x24" and the bench to the left is 5'x32".

I am 100% going to build a gun rack to go on the wall to the right of the shelves. It's a pain when I take rifles out of the safe and put them all over the place trying to get to one in the back. A gun rack or maybe two will be very useful.

View attachment 961148

View attachment 961149

horsemen61 said:Room looks awesome can’t wait to see that Gun Rack!!!!!

Thanks. I'll post pictures of the entire room once I'm done which should be soon. I'm still thinking about the design and materials for a wall-mounted gun rack. I know it'll involve steel and welding though!

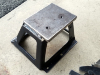

I'm an inveterate hoarder when it comes to anything metal and I've been thinking about re-purposing the item shown below. Does anyone know what it is, and more importantly, what I'm thinking of using it for? Hint: If you have a Dillon press you might have a good idea.

View attachment 961413

View attachment 961411

I'm an inveterate hoarder when it comes to anything metal and I've been thinking about re-purposing the item shown below. Does anyone know what it is, and more importantly, what I'm thinking of using it for? Hint: If you have a Dillon press you might have a good idea.

View attachment 961413

View attachment 961411

Looks like a spare tire holder off a Jeep.I'm an inveterate hoarder when it comes to anything metal and I've been thinking about re-purposing the item shown below. Does anyone know what it is, and more importantly, what I'm thinking of using it for? Hint: If you have a Dillon press you might have a good idea.

BreechFace said:But today after knocking the bolts off, a little bit of cleanup, paint and new bore holes in a specific layout it looks like a riser stand for a Dillon press.

WeekendReloader said:Could be used as a nice press stand.

BreechFace said:I was an overland adventurer in my college days, had to get away from civilization somehow. I passed a lot of Jeeps on the trail in my Tacoma.

If I had a $ for every Toyota I've had to winch out of puddles over the last 20 years it would pay for my walk-in gun vault!In fact, a Toyota driving father and son from 2008 or so still owe me money from a recovery that took more than 3 hours ... bastards never paid me!

I've done a lot of rock crawling but overland is way more fun, and tends not to break as many parts. .

It looks to be one of a pair of mounting stands used to mount a "fifth wheel" trailer hitch onto a pickup truck bed.I'm an inveterate hoarder when it comes to anything metal and I've been thinking about re-purposing the item shown below. Does anyone know what it is...

View attachment 961413