I am going to say, the basic problem is, how do you or your gunsmith prove the action is metallurgically sound and safe? Reputation is one thing, old steel varies considerably, there is little to no consistency in the stuff. Claiming there are "good years" sort of assumes that all receivers in the "good years" are good. Not so, production in any period produces good things, and bad things off the same production line. If I were going to use a vintage receiver as a basis for a custom rifle, I would prefer a receiver that was "proven good". And I don't know how to do that. Not doing that risks injury, and a total waste of money if something breaks.

The older the receiver, the more suspect the metallurgy is. Something like a 1891 Argentine, that is very old. At the time the Germans were going through a scandal with their GEW 1888’s blowing up. Look at the book "

German Military Rifles , 88 and 91 firearms" by Dieter Storz. Mr Storz has a significant section on the

"Judenflinten" (Jewish Gun) scandal and metallurgical failures of the 1888 Commission rifles. The 1888 was an early smokeless round, the metals of the era, plain carbon steels had a lot of slag and impurities. So the occasional Ludwig and Loewe made 1888 blew up. And so did the occasional 1888's made by other manufacturers. But the fact that Ludwig and Loewe were Jewish owned, allowed German Anti Semitics to claim:

The next scandal was caused by a pamphlet of (Hermann) Ahlwardt, “ Judenflinten,” (jewish guns)

in which he accused the armament firm of Ludwig Lowe of being bribed by the Alliance Israelite of Paris to deliver inferior guns to the Prussian Army , so that the latter might be defeated in the next war of revenge. The falsity of the charge was proved by a Government official, but it was not until after thousands of copies of the pamphlet had been sold in the streets that it was confiscated, and Ahlwardt, after prosecution, was sentenced to five months imprisonment

the German author here:

Making Steel after 1870

states the Bessemer process produced ****ty iron and steel.

I really doubt the other processes made vastly better steel. Steel to the 1950’s had residuals, slag, and impurities. The older the steel, the more residuals, slag, and impurities you can expect.

Mausers up to 1918 were built for a round that operated at 43,371 psia. That includes the 6.5 X 55, 7 X57, and 8 X57.

Rifle Magazine Issue 159 May 1995 Dear Editor pg 10

Ludwig Olsen

Mauser 98 actions produced by Mauser and DWM were proofed with two loads that produced

approximately 1000 atmosphere greater pressure than normal factory rounds. That procedure was in accordance with the 1891 German proof law. Proof pressure for the Mauser 98 in 7 X57 was 4,050 atmospheres (57, 591 psi). Pressure of the normal 7 X 57 factory load with 11.2 gram bullet was given in Mauser’s 1908 patent boot as 3,050 atmosphere, or 43, 371 pounds.

While many Mausers in the 1908 Brazilian category will likely endure pressures considerably in excess of the 4,050 atmospheres proof loads, there might be some setback of the receiver locking shoulder with such high pressures.

WW2 Mausers used a 46,500 psia cartridge, I don’t know the time of transition.

Run the numbers, you will find modern cartridges such as the 308 Win are operating above the proof pressures of the original military actions.

A fellow shooter who is hired on firearm liability lawsuits told me to

“avoid wartime production, and that includes ours!”. That is not exactly comforting, but we do know standards are vastly relaxed during wartime. We also know conscripted German Jewish workers were actively sabotaging Nazi production, and after the German Jews were sent to the gas chambers, replacement slave laborers were brought in, and were also actively sabotaging Nazi war material production. German wartime metallurgical quality is therefore, iffy, if not unknown. Ditto for Japanese slave labor. The Japanese set up huge factories in China and manned them with Chinese slaves. It can be safely assumed , slaves wherever they are, are unhappy, and are not going to be contentious workers.

Period steels made by happy American’s had its issues:

PG&E Alerted To Risk of Worn Hooks Back in 1987

PG&E was alerted more than 30 years before the deadly Camp fire about the failure risk of worn steel hooks like the one that snapped and caused the most destructive wildfire in state history, documents obtained by NBC Bay Area’s investigative unit show.

www.nbcbayarea.com

PG&E was alerted more than 30 years before the deadly Camp fire about the failure risk of worn steel hooks like the one that snapped and caused the most destructive wildfire in state history, documents obtained by NBC Bay Area’s investigative unit show.

According to a February 1987 engineering evaluation, the company ordered the tests of two worn hooks that were found on a transmission line in Contra Costa county – hooks that look chillingly similar to ones taken from the nearly 100-year-old transmission line blamed for the fire that left 85 dead.

The two grooved hooks, as well as a third hook with no visible wear, all failed at loads far lower than capacity. The PG&E report called for more testing of hooks in stock for its system, especially given that unworn hook failed at about one quarter of the load it was supposed to handle. That was actually worse than the two worn hooks, however, which failed at about one third of the specified capacity of 30,000 pounds.

The report can be found here:

https://s3.documentcloud.org/documents/6588959/PG-E-1987-Report-on-Worn-C-Hooks-J-Hooks.pdf

Old Joe remembered a 1930 National Geographic ad in which Chrysler bragged that its cars could go 33,000 miles before valve grinding! I did find a 1932 Chrysler Imperial owners manual pdf on the web, and it had a section on valve grinding.

Start at page 52

https://www.web.imperialclub.info/Yr/1932/32Owners/Page052.htm

I really doubt anyone here has ground their valves recently. This was interesting, a Mauser in the “good period” blowing its barrel.

Mauser belge Kaboom

https://armes-et-tirs.forumpro.fr/t12653-mauser-belge-kaboom

His Belgian mauser of 1935 exploded at the level of the affraid chamber it was not a bullet stuck in the barrel, not a cartridge reloaded too hard, no, just a weapon whose steel had decided that it was the blow too much Evil or Very Mad My friend escapes unscathed left for a good fright. But it is to meditate, a weapon has its limit in time and even without martyring it, one day it can fart you to the g..... e

It's called metal fatigue, it's best known in aviation. It should also be noted that the steels of those years are less elaborate and refined than those of today, there are a lot of impurities, especially residues of other soft metals. From the danger of old weapons: always be wary of them, observe if nothing moves after each shooting session, a digital caliper, a notebook and take notes on the most sensitive points, as here the Ø outside the room.

The “safest” approach is not to buy some old military action and use it at all. There are plenty of nice, new, actions made of modern materials. I am going to claim the actions built in the 1930’s, were built in a period of peace, and metallurgy was much improved over the pre 1918 stuff. Even so, as the 1935 Mauser above, it was not perfect. Quality and consistency varied.

But if you have to have a military action do not chamber the rifle in a cartridge that exceeds the period operating pressures, nor the bolt loading of the original cartridge.

Exceed the bolt loading, by going to a belted magnum for example, and you may experience lug set back.

6.5 Swede Mauser and loading manuals

I shoot a model 94 Swedish mauser with the 17.5 inch barrel so bullet speeds are slow. Hornady lists 44 grains IMR 4350 with their 140 grain bullet as Max load. Everyone else lists 45 grains of the same powder and bullet weight as Max. Is Hornady just cautious or is their bullet bearing...

www.thehighroad.org

@22250Rem

This thread had become very interesting and informative. Since my last two posts back in November I came across something on another site that dealt with the Swedish Mauser receivers that Kimber had re-barreled to higher pressure rounds like .308, .243 and .22-250. They said that those re-barreled Swedes eventually developed "set back" issues. Wouldn't that be due to the lugs and/or the lug recesses deforming under excessive repeated pressures and creating excessive headspace? I'm glad my Kimber Swede is still in the original 6.5x55 chambering as I've not heard or seen anything about problems with those. I'm sure my headspace is still correct after 23 years because I reload everything that goes into it (pretty much just one load nowadays; a 129 gr. Hornady at about 2620 fps, nice but not a hot rod) and brass seems to last through many, many reloading cycles. So would I be correct on my assumption that those "set back" issues were due to lugs / lug recesses deforming at those higher pressures?

@boom boom

Yes. I did not add the Kimber experience as I usually run long on posts anyway but you are correct. Firing these rifles over time with higher pressure rounds does cause lug setback which will eventually cause the rifle to become unserviceable. The high pressure when the bolt is locked swages the softer underlying material in the lug locking recesses in the receiver producing ridges, humps, etc. It can be felt if you have small enough fingers or a dental mirror and light can help determine it. It is often diagnosed as problems with the chamber or extractor as it becomes more difficult to run the bolt properly when this happens. Try a bing image search for mauser lug setback for some good pictures of this.

argentine mauser build or sell?

forums.accuratereloading.com

Kabluewy:

I found that one of the 1909 actions was already set back from the military ammo.

Another one set back after I had it barreled.

Later, I sent another one, unmodified, to a barrel maker to install one of their barrels, but they refused. They said the action was too soft, and they wouldn't install one of their barrels.

I have had several other good mil-surp actions, all sold now but three.

I managed to get rid of all the 1909s, at a significant loss.

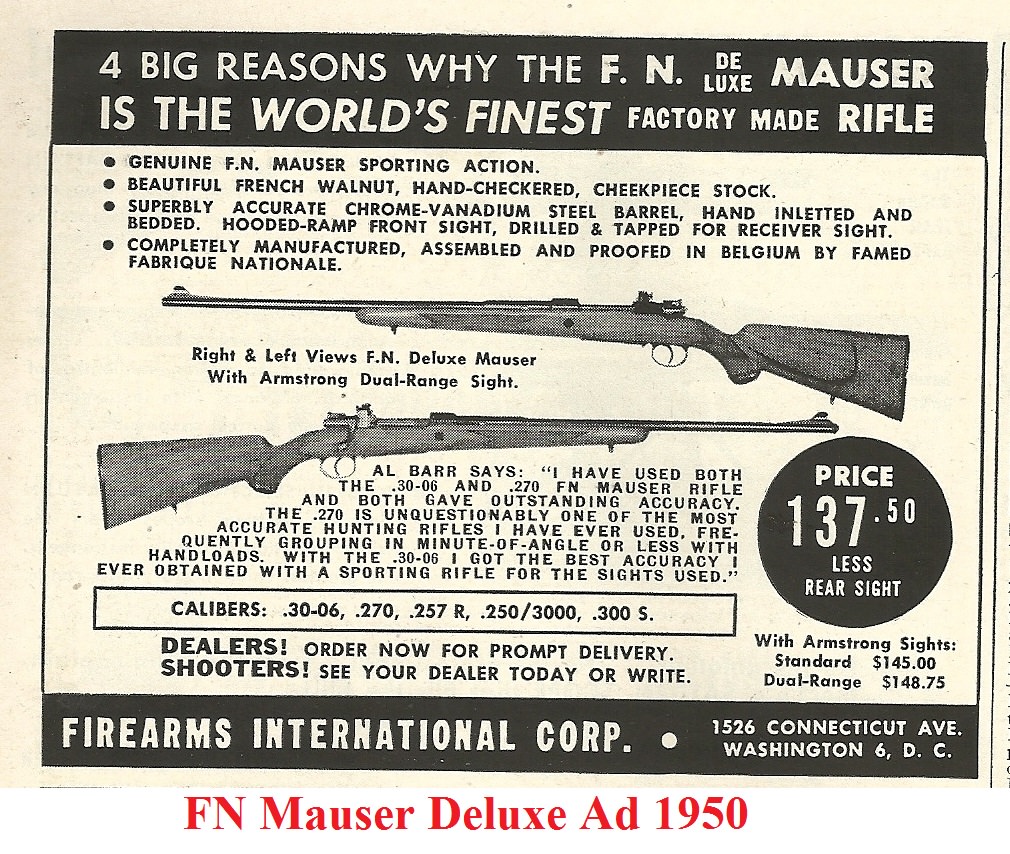

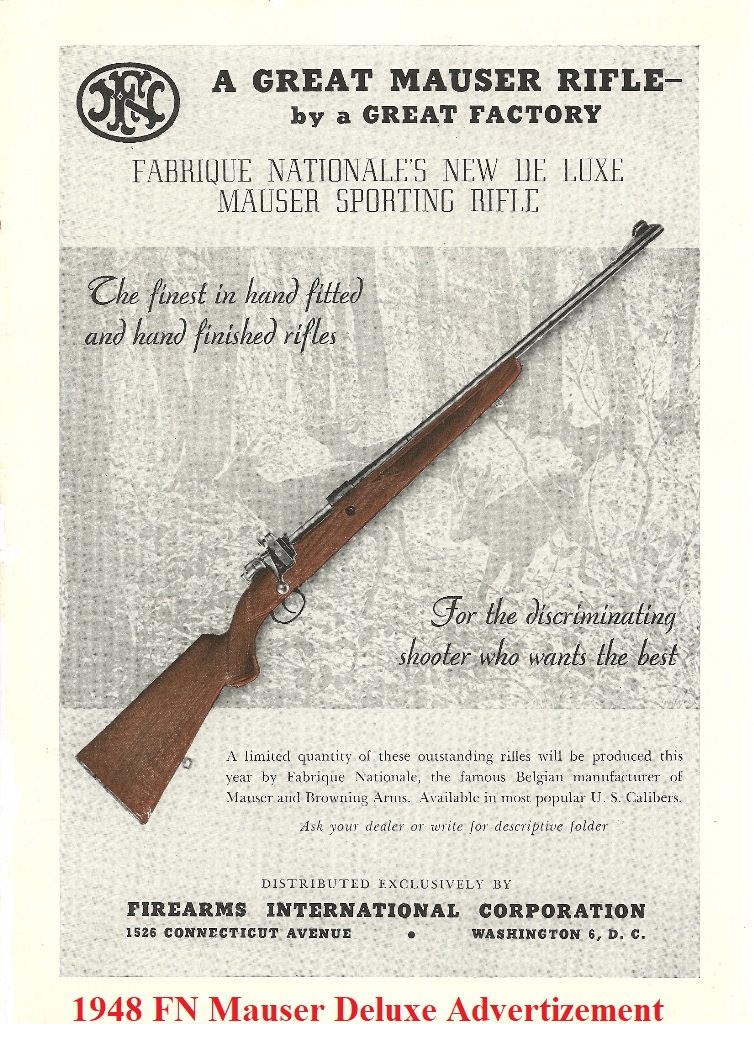

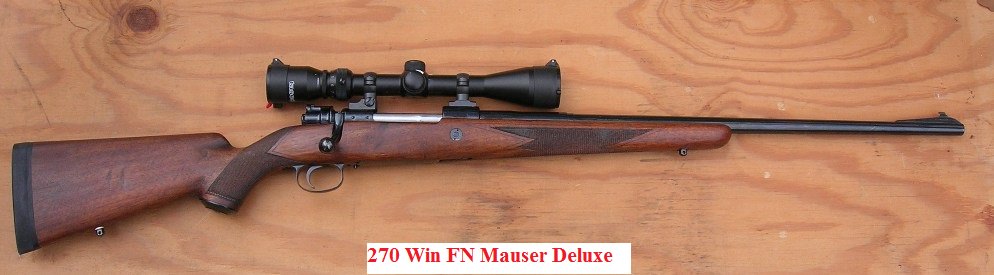

I believe the "safetest" non communist block Mausers are going to be the post WW2 FN Actions. They were not cheap then, in fact, cost more than a contemporary pre 64 M70.

If you look, you can find them. They still ain't cheap:

But at least they were built for 30-06, 270 Win cartridges. They were too structurally weak for Weatherby magnums.

You can look at the history, Weatherby claimed he could not get the "quality" he wanted from FN, and therefore had to make his own action. I am certain, given the bolt thrust of his cartridges, the lugs were cracking on FN Deluxe actions, and that's why he had to create his massive action.

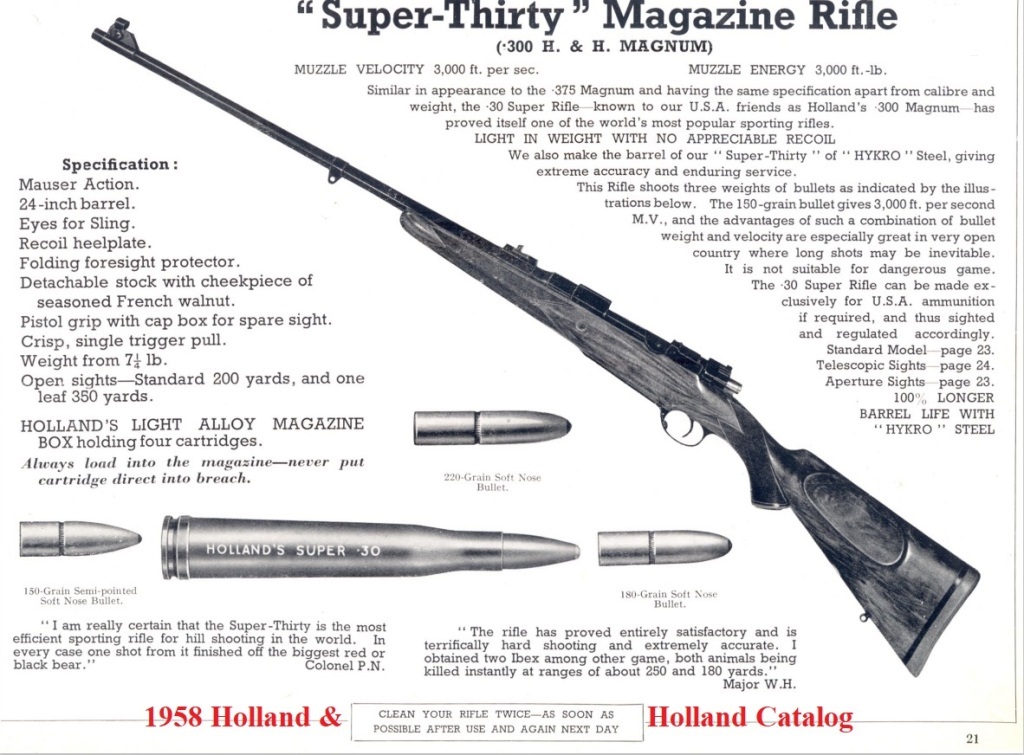

Late 1950's FN actions used by H&H, were not operating at US "Magnum" pressures:

Someone can run the numbers and see what it takes to push a 150 grain bullet 3000 fps in a 24 inch barrel with a 300 H&H cartridge.

Take a look at the price of creating a custom rifle around a military action, and compare to the price of a used FN Deluxe. If the FN Deluxe is equal to , or less, get the FN Deluxe.