ColoradoMinuteMan

Member

- Joined

- May 8, 2015

- Messages

- 702

Request:

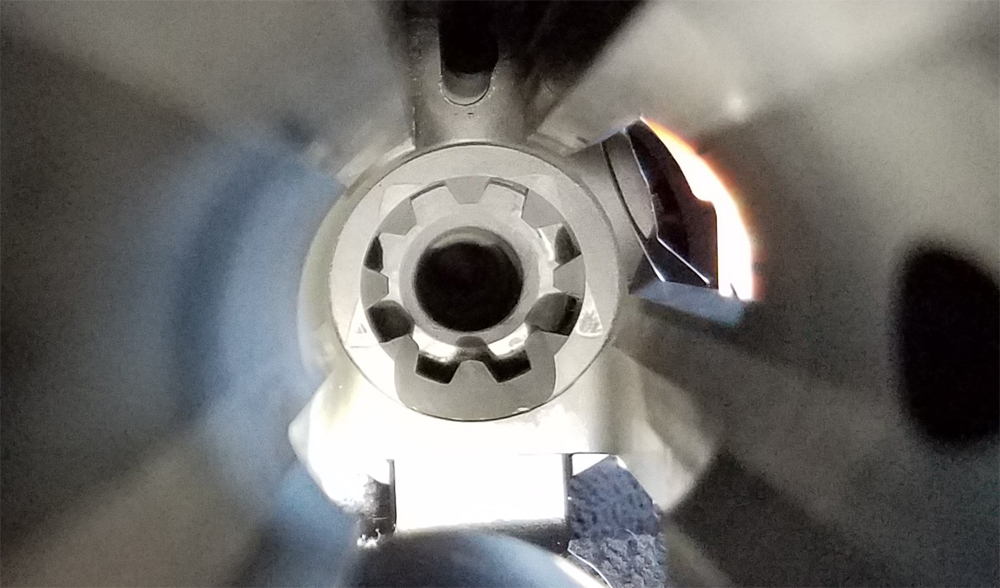

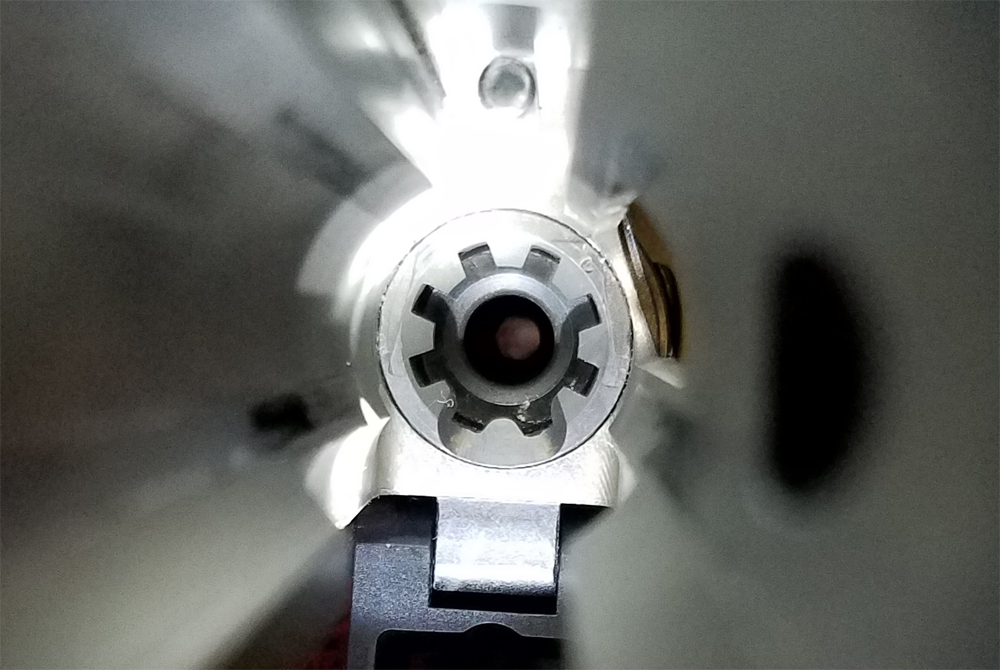

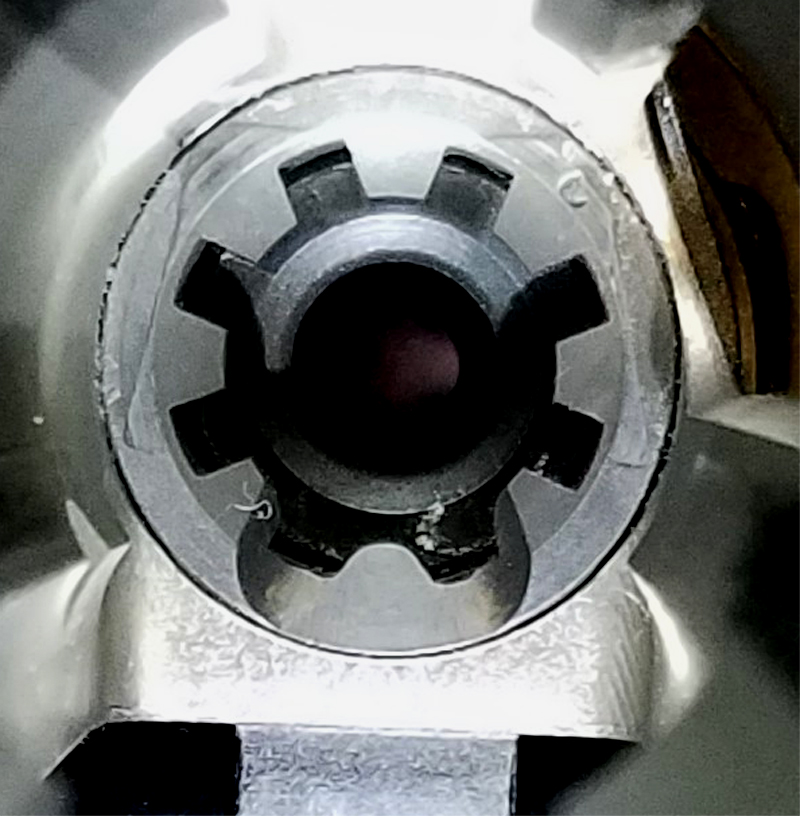

So, I'm looking for a little help here. I'm hoping that you can share a picture of the feed-ramps on your .308 AR with DPMS pattern barrel extension. If you can share the make of barrel an the make of the upper receiver that would help even more.

History:

We all know that the .308 AR doesn't have as much standardization as the AR-15 platform. I run into an issue that started showing itself as I began diagnosing some issues I discovered while reloading .308 ammunition from my .308 AR. At first I thought my loads were causing the case necks to split, but as it turns out it was a fairly deep scratch. I also found that there were several dents in the shoulder of the extracted cartridges. I didn't think much about it until my next range trip when I got a failure for the bolt to go into battery. It was difficult to manually extract the cartridge. I took a look at the cartridge and sure enough it had a massive dent on the shoulder.

I went home to diagnose the issue. The first thing I found was that the barrel extension was full of shavings of brass, much more than I had ever seen before. I tend to see a few flecks in my ARs from time to time but this was really bad for only shooting about 50 rounds. I made up a few dummy rounds to play with and I found the differential between my feed-ramps on the upper receiver and barrel extension was causing a nasty impact to the case neck and should which was causing the shaving and the deformed cases.

Anyway, I knew that there was not perfect alignment of the feed-ramps when I assembled this .308 AR using Aero Precision receivers and a Faxon barrel. My thought process at the time was that the smaller ramps feeding into the wider ramps will probably be fine. That doesn't appear to be the case. I know that I can correct this issue by blending the ramp using a file, but I'm not ready to do that quite yet. What I'd like to do is get a sampling of feed ramps from various vendors to determine if either the Faxon barrel ramps are unusually wide or the Aero Precision receiver ramps are unusually narrow. That way I can see which way I want to handle this. I don't want to widen the receiver ramps knowing that they will then be too wide for every other barrel extension I may replace it with down the road. If it is a matter of Faxon just being widely out of spec, I'll handle this with them. However, if it is simply a matter of Aero Precision just being conservatively narrow, then I don't mind adjusting them.

Thank you in advance.

So, I'm looking for a little help here. I'm hoping that you can share a picture of the feed-ramps on your .308 AR with DPMS pattern barrel extension. If you can share the make of barrel an the make of the upper receiver that would help even more.

History:

We all know that the .308 AR doesn't have as much standardization as the AR-15 platform. I run into an issue that started showing itself as I began diagnosing some issues I discovered while reloading .308 ammunition from my .308 AR. At first I thought my loads were causing the case necks to split, but as it turns out it was a fairly deep scratch. I also found that there were several dents in the shoulder of the extracted cartridges. I didn't think much about it until my next range trip when I got a failure for the bolt to go into battery. It was difficult to manually extract the cartridge. I took a look at the cartridge and sure enough it had a massive dent on the shoulder.

I went home to diagnose the issue. The first thing I found was that the barrel extension was full of shavings of brass, much more than I had ever seen before. I tend to see a few flecks in my ARs from time to time but this was really bad for only shooting about 50 rounds. I made up a few dummy rounds to play with and I found the differential between my feed-ramps on the upper receiver and barrel extension was causing a nasty impact to the case neck and should which was causing the shaving and the deformed cases.

Anyway, I knew that there was not perfect alignment of the feed-ramps when I assembled this .308 AR using Aero Precision receivers and a Faxon barrel. My thought process at the time was that the smaller ramps feeding into the wider ramps will probably be fine. That doesn't appear to be the case. I know that I can correct this issue by blending the ramp using a file, but I'm not ready to do that quite yet. What I'd like to do is get a sampling of feed ramps from various vendors to determine if either the Faxon barrel ramps are unusually wide or the Aero Precision receiver ramps are unusually narrow. That way I can see which way I want to handle this. I don't want to widen the receiver ramps knowing that they will then be too wide for every other barrel extension I may replace it with down the road. If it is a matter of Faxon just being widely out of spec, I'll handle this with them. However, if it is simply a matter of Aero Precision just being conservatively narrow, then I don't mind adjusting them.

Thank you in advance.