I do the same… I think it’s 3” pvc drain pipe. (Measure your die plate and take a tape measure to HD)! Sometimes they have short lengths in bins for quick repairs.Clever. What size PVC pipe did you use?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What clever little things have you "invented or discovered" that you can share?

- Thread starter James THR

- Start date

refuse2bafool

Member

Duh. I could have done that. Or I could have just taken the bottom of a red round box with me to the hardware store. Silly me. Type before thinking sometime.I do the same… I think it’s 3” pvc drain pipe. (Measure your die plate and take a tape measure to HD)! Sometimes they have short lengths in bins for quick repairs.

But thanks.

Bobaloo22

Member

- Joined

- Sep 19, 2019

- Messages

- 139

It is 3” schedule 40.Clever. What size PVC pipe did you use?

DustyRusty

Member

- Joined

- Jan 14, 2020

- Messages

- 292

toxophilus

Member

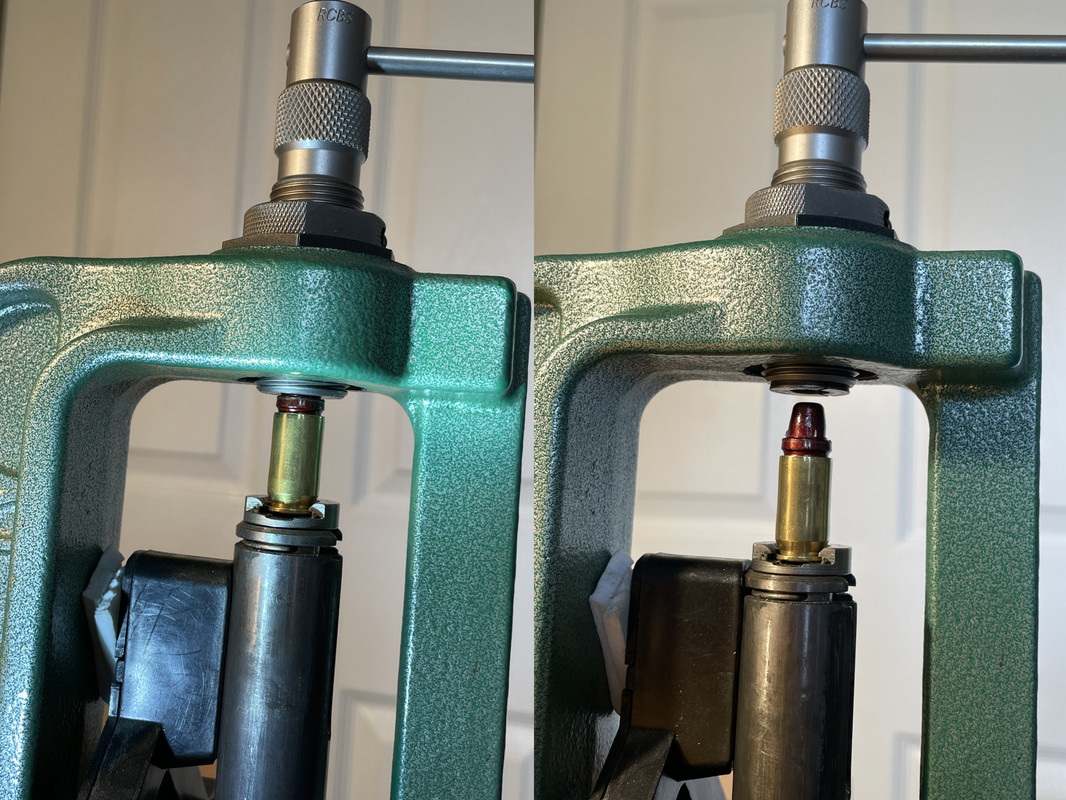

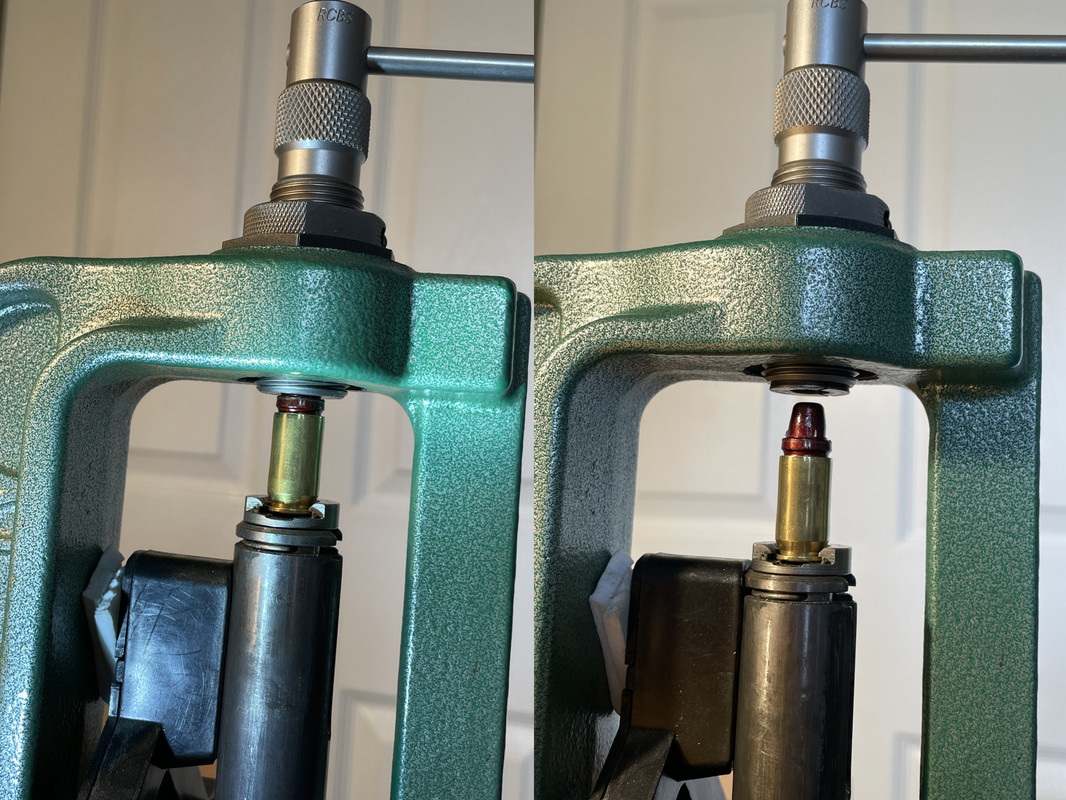

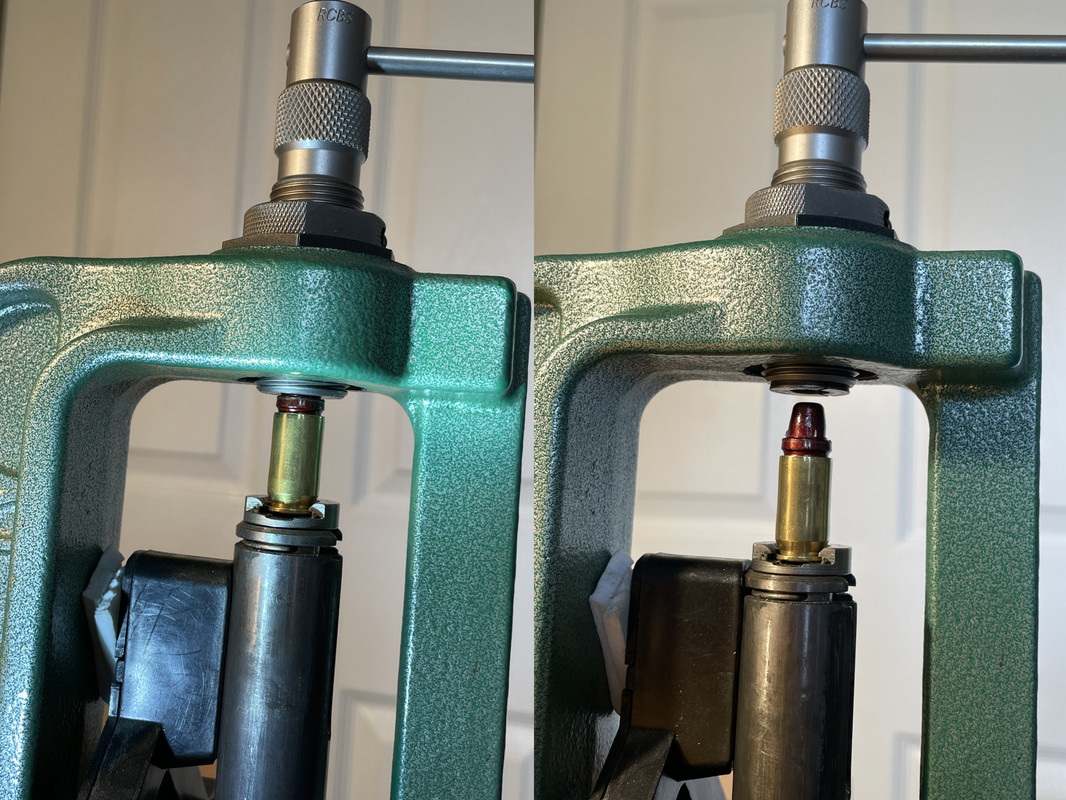

I needed to pull a gaggle of .45 SWC loads that I had previously built; using my RCBS bullet puller I measured above the shoulder of the base of the wadcutter where it starts to taper and the measurement came out to be around 35 caliber dimensions; I used my .357 collet to pull these rounds (it worked great without deforming the cone tapered part of the bullet).

That’s a perfect solution!I needed to pull a gaggle of .45 SWC loads that I had previously built; using my RCBS bullet puller I measured above the shoulder of the base of the wadcutter where it starts to taper and the measurement came out to be around 35 caliber dimensions; I used my .357 collet to pull these rounds (it worked great without deforming the cone tapered part of the bullet).

James Collins

Member

- Joined

- Jul 30, 2019

- Messages

- 167

I remember using those loopy thingsMy primers end up here. The tethers on the bench leg are tent peg loopy things.

View attachment 1176144

barnfrog

Member

I respectfully request that you refrain from using such technical jargon. It's obvious you're just trying to show off your immense vocabulary.My primers end up here. The tethers on the bench leg are tent peg loopy things.

James Collins

Member

- Joined

- Jul 30, 2019

- Messages

- 167

Haha

Freudianfloyd

Member

Delete

Last edited:

entropy

Member

Neat, but how does that relate to Handloading?

Freudianfloyd

Member

Sorry, didn't realize it was in the handloading section. In that case, I will quietly back out of the room.Neat, but how does that relate to Handloading?

HEAVY METAL 1

Member

- Joined

- Jan 18, 2005

- Messages

- 418

Perhaps this will be of some help to someone, somehow. I bought a RCBS powder thrower at a yard sale for only $2.00. The drum for rifle powder was rusty and while RCBS may have been willing to send me a drum for free I just didn't feel right even asking them. I used 0000 steel wool, lots of elbow grease and oil to buff the rust off, then rubbing alcohol to remove all traces of the oil and steel wool residue. I applied several coats of cold blue and the drum has been rust free now for several years.

sparkyv

Member

Like this? And this happened in my reloading room (garage)!  Fortunately, I caught it before going beyond just surface damage.

Fortunately, I caught it before going beyond just surface damage.

Perhaps this will be of some help to someone, somehow. I bought a RCBS powder thrower at a yard sale for only $2.00. The drum for rifle powder was rusty and while RCBS may have been willing to send me a drum for free I just didn't feel right even asking them. I used 0000 steel wool, lots of elbow grease and oil to buff the rust off, then rubbing alcohol to remove all traces of the oil and steel wool residue. I applied several coats of cold blue and the drum has been rust free now for several years.

entropy

Member

Perhaps this will be of some help to someone, somehow. I bought a RCBS powder thrower at a yard sale for only $2.00. The drum for rifle powder was rusty and while RCBS may have been willing to send me a drum for free I just didn't feel right even asking them. I used 0000 steel wool, lots of elbow grease and oil to buff the rust off, then rubbing alcohol to remove all traces of the oil and steel wool residue. I applied several coats of cold blue and the drum has been rust free now for several years.

Hmmm........maybe I should try that with guns sometime.

And it's not rust free........blueing is a form of rust, only because selenium is used, (at least in cold blue) the rust is blue-black in color.

Good save, nonetheless.

JohnMc

Member

Cold blue is typically copper selenide deposited on the surface. It is a layer of protection.

Hot bluing results in iron oxides that are stable, black, and don't flake. Magnetite is one.

Hot bluing results in iron oxides that are stable, black, and don't flake. Magnetite is one.

Andrew Leigh

Member

RCBS Chargemaster 1500 accuracy. I could never get my Chargemaster to throw accurate loads consistently. It was so bad that I packed her back in the box and reverted back to my RCBS beam scales.

I then read about the McDonalds straw conversion which was supposed to help but did not do much for me. In my research I happened upon an article that credited a fellow South African with the modification that worked.

Step 1

1. I searched for found and metal straw that was a nice firm slide fit up the dispensing tube. The straw was cut to remove the belled over edge at the end, the end was cut and deburred and this end was inserted into the dispensing tube. This straw protrudes into the powder pick up area as follows;

There is a gap of circa 13/64".

2. The straw was then marked at the point where it protruded circa 25/64" out from the existing dispensing tube and then it was cut and deburred. The straw does two things, it reduces the amount of powder pickup which in turn improved the accuracy. Secondly the straw cancels out the coarse thread of the dispensing tube which dispenses too rapidly.

[

Step 2

3. The software that alters the ramp up, dispensing and slow down speed are accessible to the normal user. There are three parameters that can be tweaked to suit your specific needs. The system is really simple and is laid out below. For interest my setting are in bold below. The calibers are 6.5x55mm to .375H&H

With that out of the way time for the software. The first three parameter ONLY require changing. My parameters have been fine for 6.5mm to .375 loading.

a. Turn the Chargemaster 1500 unit on.

b. When 0.0gn. is on the display, press BOTH the ENTER and the EDIT MEM keys on the dispenser at the same time. Hold for a second and then release. If done properly ADJUST PARAMETERS should scroll across the display followed by HSP_A1 00015.68 (This number represents the number of grains away from your entered charge when the tube will shift from fast speed to medium speed. That is at 15.68gn. from your target charge the dispenser will shift from fast to medium speed.) To speed up the unit, this number needs to be decreased, and to slow down the unit, this number needs to be increased. I have mine set on 8.0gr. this is done by pressing the following keys: 8 0 0 ENTER (pressing the enter key sets that value and moves to next setting in program in this case, to medium speed to slow speed setting)

c. HSP_B1 00003.42 should scroll across the display now. This number represents where the unit will shift from medium to slow speed. Use the same process as in step 2 to enter updated values. I have set mine to 2.50gr. this is done by pressing the following keys: 2 5 0 ENTER (pressing the enter key sets that value and moves to the next setting in the program. In this case, the slow speed to trickle speed transition)

d. HSP_C1 00001.08 should now scroll across the screen. This number represents where the unit will shift from slow speed to trickle. Use the same process as before to enter the value. I have mine set to 1.0gn. This is done by pressing the following keys: 1 0 0 ENTER

e. This is all the adjustment that needs to be done to the unit. You then need to press the ENTER key to cycle through the rest of the program without changing any of the values (approx. 22 times). Once complete, the unit will start its normal initial countdown process. Next, test the dispenser by entering a target charge (i.e. 44.5 ENTER, and pressing DISP). Disregard the first charge and throw a few charges at these settings to see if they satisfy your needs. If not, return to step 2 and repeat the process to program in different values.

NOTE: Due to powder variations, you may have to adjust the unit for each different powder type used. I use it for stick powders and use three different local variants and have seen no need to alter the settings.

I then read about the McDonalds straw conversion which was supposed to help but did not do much for me. In my research I happened upon an article that credited a fellow South African with the modification that worked.

Step 1

1. I searched for found and metal straw that was a nice firm slide fit up the dispensing tube. The straw was cut to remove the belled over edge at the end, the end was cut and deburred and this end was inserted into the dispensing tube. This straw protrudes into the powder pick up area as follows;

There is a gap of circa 13/64".

2. The straw was then marked at the point where it protruded circa 25/64" out from the existing dispensing tube and then it was cut and deburred. The straw does two things, it reduces the amount of powder pickup which in turn improved the accuracy. Secondly the straw cancels out the coarse thread of the dispensing tube which dispenses too rapidly.

[

Step 2

3. The software that alters the ramp up, dispensing and slow down speed are accessible to the normal user. There are three parameters that can be tweaked to suit your specific needs. The system is really simple and is laid out below. For interest my setting are in bold below. The calibers are 6.5x55mm to .375H&H

With that out of the way time for the software. The first three parameter ONLY require changing. My parameters have been fine for 6.5mm to .375 loading.

a. Turn the Chargemaster 1500 unit on.

b. When 0.0gn. is on the display, press BOTH the ENTER and the EDIT MEM keys on the dispenser at the same time. Hold for a second and then release. If done properly ADJUST PARAMETERS should scroll across the display followed by HSP_A1 00015.68 (This number represents the number of grains away from your entered charge when the tube will shift from fast speed to medium speed. That is at 15.68gn. from your target charge the dispenser will shift from fast to medium speed.) To speed up the unit, this number needs to be decreased, and to slow down the unit, this number needs to be increased. I have mine set on 8.0gr. this is done by pressing the following keys: 8 0 0 ENTER (pressing the enter key sets that value and moves to next setting in program in this case, to medium speed to slow speed setting)

c. HSP_B1 00003.42 should scroll across the display now. This number represents where the unit will shift from medium to slow speed. Use the same process as in step 2 to enter updated values. I have set mine to 2.50gr. this is done by pressing the following keys: 2 5 0 ENTER (pressing the enter key sets that value and moves to the next setting in the program. In this case, the slow speed to trickle speed transition)

d. HSP_C1 00001.08 should now scroll across the screen. This number represents where the unit will shift from slow speed to trickle. Use the same process as before to enter the value. I have mine set to 1.0gn. This is done by pressing the following keys: 1 0 0 ENTER

e. This is all the adjustment that needs to be done to the unit. You then need to press the ENTER key to cycle through the rest of the program without changing any of the values (approx. 22 times). Once complete, the unit will start its normal initial countdown process. Next, test the dispenser by entering a target charge (i.e. 44.5 ENTER, and pressing DISP). Disregard the first charge and throw a few charges at these settings to see if they satisfy your needs. If not, return to step 2 and repeat the process to program in different values.

NOTE: Due to powder variations, you may have to adjust the unit for each different powder type used. I use it for stick powders and use three different local variants and have seen no need to alter the settings.

ballman6711

Member

When removing the ram from my single stage press for cleaning, I leave a shell holder in place on top of the ram. When taking the linkage off, if you slip you won't drop the ram onto the floor, or your foot, because the little wire that holds the shell holder sticks out just enough to catch it. Once the linkage is off, the shell holder is easily removed so the ram can be lowered/removed and cleaned.

When putting the press back together, slide the ram up into the frame, put a shell holder on, and it won't fall out while you reattach the linkage.

chris

When putting the press back together, slide the ram up into the frame, put a shell holder on, and it won't fall out while you reattach the linkage.

chris

Blue68f100

Member

RCBS Chargemaster 1500 accuracy. I could never get my Chargemaster to throw accurate loads consistently. It was so bad that I packed her back in the box and reverted back to my RCBS beam scales.

I then read about the McDonalds straw conversion which was supposed to help but did not do much for me. In my research I happened upon an article that credited a fellow South African with the modification that worked.

Step 1

1. I searched for found and metal straw that was a nice firm slide fit up the dispensing tube. The straw was cut to remove the belled over edge at the end, the end was cut and deburred and this end was inserted into the dispensing tube. This straw protrudes into the powder pick up area as follows;

There is a gap of circa 13/64".

2. The straw was then marked at the point where it protruded circa 25/64" out from the existing dispensing tube and then it was cut and deburred. The straw does two things, it reduces the amount of powder pickup which in turn improved the accuracy. Secondly the straw cancels out the coarse thread of the dispensing tube which dispenses too rapidly.

[

Step 2

3. The software that alters the ramp up, dispensing and slow down speed are accessible to the normal user. There are three parameters that can be tweaked to suit your specific needs. The system is really simple and is laid out below. For interest my setting are in bold below. The calibers are 6.5x55mm to .375H&H

With that out of the way time for the software. The first three parameter ONLY require changing. My parameters have been fine for 6.5mm to .375 loading.

a. Turn the Chargemaster 1500 unit on.

b. When 0.0gn. is on the display, press BOTH the ENTER and the EDIT MEM keys on the dispenser at the same time. Hold for a second and then release. If done properly ADJUST PARAMETERS should scroll across the display followed by HSP_A1 00015.68 (This number represents the number of grains away from your entered charge when the tube will shift from fast speed to medium speed. That is at 15.68gn. from your target charge the dispenser will shift from fast to medium speed.) To speed up the unit, this number needs to be decreased, and to slow down the unit, this number needs to be increased. I have mine set on 8.0gr. this is done by pressing the following keys: 8 0 0 ENTER (pressing the enter key sets that value and moves to next setting in program in this case, to medium speed to slow speed setting)

c. HSP_B1 00003.42 should scroll across the display now. This number represents where the unit will shift from medium to slow speed. Use the same process as in step 2 to enter updated values. I have set mine to 2.50gr. this is done by pressing the following keys: 2 5 0 ENTER (pressing the enter key sets that value and moves to the next setting in the program. In this case, the slow speed to trickle speed transition)

d. HSP_C1 00001.08 should now scroll across the screen. This number represents where the unit will shift from slow speed to trickle. Use the same process as before to enter the value. I have mine set to 1.0gn. This is done by pressing the following keys: 1 0 0 ENTER

e. This is all the adjustment that needs to be done to the unit. You then need to press the ENTER key to cycle through the rest of the program without changing any of the values (approx. 22 times). Once complete, the unit will start its normal initial countdown process. Next, test the dispenser by entering a target charge (i.e. 44.5 ENTER, and pressing DISP). Disregard the first charge and throw a few charges at these settings to see if they satisfy your needs. If not, return to step 2 and repeat the process to program in different values.

NOTE: Due to powder variations, you may have to adjust the unit for each different powder type used. I use it for stick powders and use three different local variants and have seen no need to alter the settings.

I've done similar but went 1 step further. I insert the tube all the way in and drilled a hole in brass tube to reduce the amount of powder being dumped into tube. Works really good with very fine powder and tubular powder. Keeps the level low in the tube so you don't get over shoots.

Andrew Leigh

Member

Due to resume reloading 9mm and .357 soon, will make up another straw for the purpose. What size drill did you use?I've done similar but went 1 step further. I insert the tube all the way in and drilled a hole in brass tube to reduce the amount of powder being dumped into tube. Works really good with very fine powder and tubular powder. Keeps the level low in the tube so you don't get over shoots.

Blue68f100

Member

I think I used a 3/16" drill. You have to insert the tube all the way in so it can not back fill. Start off small and enlarge as needed. You can actually run 2 different size holes 180 apart and rotate the tube for what your doing.Due to resume reloading 9mm and .357 soon, will make up another straw for the purpose. What size drill did you use?

Legionnaire

Contributing Member

Cool. Have a source and dimensions for the brass tube? Interested in trying this in a Chargemaster Lite. Thanks.I've done similar but went 1 step further. I insert the tube all the way in and drilled a hole in brass tube to reduce the amount of powder being dumped into tube. Works really good with very fine powder and tubular powder. Keeps the level low in the tube so you don't get over shoots.

BreechFace

Member

- Joined

- Mar 2, 2020

- Messages

- 3,512

@Andrew Leigh

@Blue68f100

Also, is it just a snug fit that makes the metal straw turn in the tube; or are you applying any dab of adhesive to keep it in position and attached to the dispensing tube as it spins?

@Blue68f100

Also, is it just a snug fit that makes the metal straw turn in the tube; or are you applying any dab of adhesive to keep it in position and attached to the dispensing tube as it spins?

Blue68f100

Member

Mine is a brass tube I got at Hobby Lobby if my memory is any good.Cool. Have a source and dimensions for the brass tube? Interested in trying this in a Chargemaster Lite. Thanks.

@Andrew Leigh

@Blue68f100

Also, is it just a snug fit that makes the metal straw turn in the tube; or are you applying any dab of adhesive to keep it in position and attached to the dispensing tube as it spins?

The tube is just a slight friction fit, no adhesive required. If your going to use a plastic stray, Wataburger was the place that had the large dia strays that worked the best.

Andrew Leigh

Member

Being across the pond I could not tell you where to buy but the friction fit is sufficient to keep the straw in place. I used metal to avoid static, probably not an issue but why risk it.

Similar threads

- Replies

- 47

- Views

- 3K

- Replies

- 0

- Views

- 76K

- Replies

- 1

- Views

- 253

- Replies

- 60

- Views

- 3K

- Replies

- 16

- Views

- 8K