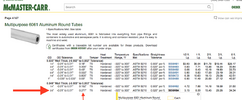

So, I was assembling a Geissele buffer tube (with their Super 42 braided wire H1 buffer spring and a Leitner-Wise bolstered buffer retainer) to a Arizona Rangers legacy M4 receiver. Wanted to use the TechCo reaction block. The problem was unlike using the Geissele block wherein the back of the castle nut can be abutted against the block to shoulder support the castle nut wrench, which prevents the wrench from slipping off / out of the castle nut notches as the torque wrench is being manipulated to spec. I needed to fabricate a wrench shoulder-support-spacer for the TechCo block as its integral buffer-receiver alignment notch does not allow the rear surface of its reaction block to support the wrench.....too much space. Fabricated aluminum spacers (0.3" & 1.2" length) to solve the current problem and future installations.

,

,

Last edited: