Michael Tinker Pearce

Member

- Joined

- Oct 23, 2016

- Messages

- 1,576

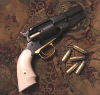

I've got a lot of oddball guns and usually have leather around owing to my to work so I am in the habit of making my own holsters. These aren't anything like professional quality but they work, and I keep trying to improve. This is my latest effort- a western-style holster for my Remington Bulldog. Fully lined, stitching inletted into the leather; it's quite stout. Not there yet, but getting closer...