So Ive got new casts for 357 Mag that I'll be trying out soon.

My old alloy was range scrap and 1% 95/5 solder, new alloy is COWW with the same 1% solder added.

NOE moulds:

360-158-WFN-T4 with the deep HP pins

Range scrap casted at 148gr

COWW casts at 146gr

360-182-WFN-U2 with the deep HP pins & alum GC (weights with GC installed)

Range scrap casted 172gr

COWW casts at 169gr

I bought a PB solid version of each profile, the solid T4 cast right at 158gr, U2s cast at 185gr with COWW alloy.

Now what I'm curious to see is how groups are going to change with my best loads accounting for the 2-3gr differences in weight.

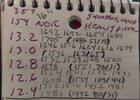

13.0gr and 12.9gr N110 are the best loads for the range scrap casts of the T4 HP and U2 HP GC respectively, I would imagine the charge may need to come up a .1gr with slightly lighter bullets of the same length and profile, but maybe not at all.

Also curious to see if those charge weights will come down significantly (.3gr or more) for the solids. 10-13gr of lead must surely make a difference in grouping and POI.

I've got a good amount of casts to figure it out though:

T4-PB HP: around 1500 by weight (to be counted and bagged)

T4-PB Solid: 1500 as well by weight, to be counted etc.

U2-GC HP: 400 or so, didn't cast as many of these because I want to move away from the GC version of the mould

U2- PB Solids: around 1200 by weight

These are all coated as of today, but I still need to size them. I have one last set of 100ct T4 PB HPs of the old range scrap alloy to load for March's silhouette match, but after that I'll need to have figured something out for the April match.