Howdy

First of all, anyone who tells you to use Trailboss in a Cap & Ball revolver simply does not know what they are talking about. Trailboss is NOT a Black Powder substitute, it is a modern Smokeless powder and is not suited for Cap & Ball revolvers no matter what anybody tells you.

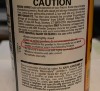

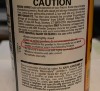

Here is what is printed on the back of a bottle of Trailboss:

****************************************************************

Correction: While Trail Boss is not recommended for Black Powder revolvers, modern conversion cylinders can be fired with Smokeless powder loads. However I still recommend against Trail Boss. It is a very fast powder, and some shooters still think it is a good substitute for Black Powder loads. I would recommend something a little bit slower, in a conversion cylinder in a steel frame, more like Unique. I would also be sure the loads are light.

*****************************************************************

The rest of this post deals with shooting Black Powder in various revolvers.

Now that we've got that out of the way, let's talk about Black Powder fouling in revolvers for a moment.

The main reason revolvers bind up with Black Powder is because fouling blasted out of the barrel/cylinder gap gets deposited on the cylinder pin. As the cylinder revolves, the fouling works its way down the pin and causes binding. Forget about the width of the barrel/cylinder gap, that has very little to do with it. Some folks will tell you to open the barrel cylinder gap to allow more space for fouling built up on the face of the cylinder. I can tell you from experience that this has little to do with BP binding. I have been shooting Black Powder in cartridges in revolvers for years, and all of them have their original factory barrel/cylinder gaps.

Those who posted about bushings on the front of the cylinder are correct. A cylinder bushing shields the underlying cylinder pin from the fouling blasted out of the barrel/cylinder gap. That is why it is there.

Here is a photo of three 45 Colt revolvers. Left to right they are from an Uberti Cattleman, stainless Ruger Vaquero, and Colt Single Action Army. You can see the bushing on the front of each cylinder. The bushings in the Cattleman and the Colt are removeable, and some will tell you that is an important feature to keep a revolver from biniding from BP fouling, but it is not true. That Ruger with the integral bushing in front shoots Black Powder cartridges just fine. I can go through an entire CAS match with any of these revolvers, and I never have to stop and clean anything. They just don't bind up.

Let's look for a moment at the relationship between the cylinder bushing and the barrel/cylinder gap. This photo of the stainless Ruger illustrates it very well. The barrel extends through the frame, to the front face of the cylinder. The cylinder bushing extends forward off the cylinder to the frame. The fouling blasted out of the barrel/cylinder gap blasts out in a pattern pretty much resembling a flat disk. So the bushing extending all the way to the frame provides enough horizontal separation to deflect the fouling away from the cylinder pin. Cylinder bushings such as this were developed during the Black Powder cartridge era for exactly this purpose, to deflect fouling away from the cylinder pin and prevent binding.

Now, let's look at a couple of Cap & Ball revolvers. The cylinder on the left is from a Pietta replica of the 1860 Colt. The cylinder on the right is from a replica 1858 Remington. The first thing we notice is there is no bushing on the front of either cylinders. They are completely flat across the front face.

Now look at the relationship of the barrel/cylinder gap to the front of the cylinder on the Remington. There is no horizontal separation, the Remington binds up quickly because there is nothing to prevent fouling blasted out of the barrel/cylinder gap from being deposited directly onto the cylinder pin. Now look back at the previous photo and notice how much larger in diameter the Colt type cylinder arbor is than the Remington cylinder pin. Notice too there is a helical pattern of grooves on the Colt arbor. The purpose of the grooves is to create clearance for any powder fouling that worked its way onto the arbor from the barrel/cylinder gap. And the larger diameter of the Colt arbor creates more surface area, so any fouling blasted onto the arbor will not build up as high to create binding. This is why the open top Colt designs generally can shoot longer with Black Powder and not foul out as badly as the Remington design does.

In point of fact, when Remington brought out their cartridge version of the 1858 in 1875, they had learned the lesson and there was a bushing on the front of the cylinder, just as there was when the Single Action Army came out in 1873. So the 1875 Remington cartridge revolver did not foul out as badly as the earlier C&B model did.

Now let's talk about cartridges for a moment. Black Powder cartridges require a different type of bullet lube than Smokeless cartridges do. Modern hard bullet lubes combine with Black Powder fouling to create a hard caked, difficult to remove fouling. Black Powder requires a softer fouling that remains soft and gooey after it becomes infused with BP fouling. There are many recipes for Black Powder bullet lubes, I used to make up a mix of about 50/50 Crisco and beeswax. These days I use a commercial BP bullet lube made by SPG. The point is, if fouling that is infused with modern Smokeless bullet lube gets blasted out of the barrel/cylinder gap and deposited onto the cylinder pin, it will tend to bind up the cylinder even quicker than the BP fouling would by itself. Use a good BP bullet lube, and plenty of it, and the fouling in the bore as well as any that gets deposited on the cylinder pin will remain softer and tend to bind up the gun less.

Which gets me to bullet selection. I used to use regular hard cast bullets for my Black Powder cartridges. I would melt the Smokeless lube out and pan lube with my Crisco/beeswax lube. But even so, the skimpy lube groove of a typical hardcast Smokeless bullet could not carry enough soft bullet lube to keep a rifle barrel covered with soft bullet lube for its entire length. The bullet would 'run out' of lube about 6" from the muzzle and leave hard fouling near the muzzle that had to be cleaned out or accuracy suffered. We could talk about lube cookies and all kinds of other stuff, but let's not go there. About this time I discovered the Big Lube family of bullets, designed specifically for Black Powder cartridges. These bullets feature a huge lube groove, that carries enough soft lube to keep a rifle barrel coated with soft lube its entire length. And they are the bees knees in revolvers too.

On the left in this photo is a 44-40 cartridge, and on the right is a 45 Colt. Next to each cartridge is their respective bullets, the 200 grain 44 caliber Mav-Dutchman Big Lube bullet for the 44-40, the 250 grain PRS Big Lube bullet for the 45 Colt. Each bullet is pictured with and without lube. Notice how huge the lube grooves are. These bullets carry enough lube to keep a rifle barrel lubed its entire length, and using them will also make almost any revolver perform like a champ with Black Powder.

Yes, I did say almost. Sadly, the exception is the 44 caliber 1858 Remington. Because of the lack of a cylinder bushing on this design, and the narrow cylinder pin with no relief cuts, the Remington still tends to foul out more quickly than any other revolver that I shoot with Black Powder. Even with the Big Lubes.

But take heart. You may have noticed the Remington I have pictured is equipped with the exact same style of conversion cylinder as the Original Poster's Remington. My solution is simple. Unlike the conversion cylinders that feature a loading gate, this style needs to be popped out of the frame to be loaded. Every time I reload, I wipe off the front of the cylinder with a damp cloth, wiping away any fouling that has built up on the face of the cylinder. In addition, while the cylinder is out of the gun, I take a quick peek at the cylinder pin and wipe off any fouling that has built up with the same damp cloth. Simple. Then I reload, pop the cylinder back in, and I am ready to go.

I actually have two Remingtons that have this style of conversion cylinder, and sometimes bring them to a CAS match. At the unloading table I do a quick wipe down, and am ready to load again. I can get through an entire match this way, without the Remingtons binding up.

P.S. you may have noticed that I cut some grooves into the cylinder pin of my Remington, in an effort to mimic the clearance grooves on the Colt style pin. Unfortunately, they really don't help much. Before a match I load up the pin and the grooves with Bore Butter, but the effect is only marginal, it has not helped much. But it is easy enough to cut some grooves chucking the pin into a drill press and using a file. Caution: don't cut too deep.

P.P.S Yes, it is possible for a skilled gunsmith to install a bushing on the front of the cylinder of a Remington style cylinder. I know one smith who used to do this, but he is retired now. Obviously, a clearance cut needs to be cut into the frame of the revolver for the bushing to nestle in.

P.P.P.S Here is the website of BIg Lube bullets. They only sell molds, not bullets. But they will send you a small sample of bullets to try out.

https://www.biglube.com/

I have not cast my own Big Lube bullets in a few years. Now I buy them from this guy:

http://www.whyteleatherworks.com/BigLube.html